Production Description:

HC-276 nickel alloy spray wire is designed for thermal spray applications, offering outstanding resistance to a wide range of corrosive environments. It excels in protecting equipment exposed to harsh chemicals, including acids and chlorides. Commonly used for coating pumps, valves, and heat exchangers, this wire ensures enhanced durability and extended service life in aggressive industrial settings.

Advantages of HC-276 Nickel Alloy Spray Wire

Exceptional Corrosion Resistance: Offers superior protection against a wide range of aggressive chemicals, including acids, chlorides, and seawater environments.

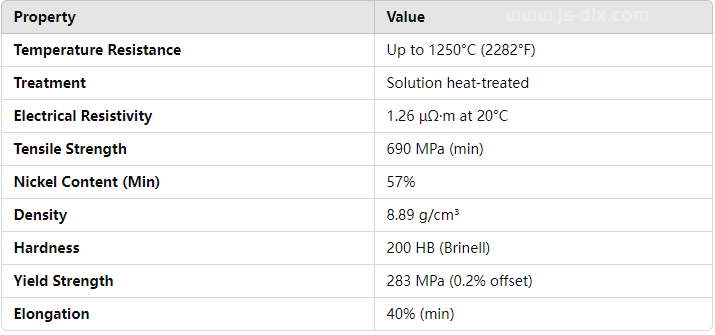

High-Temperature Stability: Performs well in extreme temperatures, with resistance up to 1250°C, making it suitable for demanding industrial applications.

Versatile Applications: Ideal for thermal spray coatings on pumps, valves, heat exchangers, and other critical components exposed to harsh environments.

Mechanical Strength: High tensile strength and yield strength ensure durability and long service life in challenging conditions.

Good Ductility: Excellent elongation properties, allowing it to withstand mechanical stress and deformation.

Low Electrical Resistivity: Provides reliable performance in environments where electrical properties are important.

Ease of Application: Compatible with various thermal spray techniques, ensuring efficient and consistent coating processes.

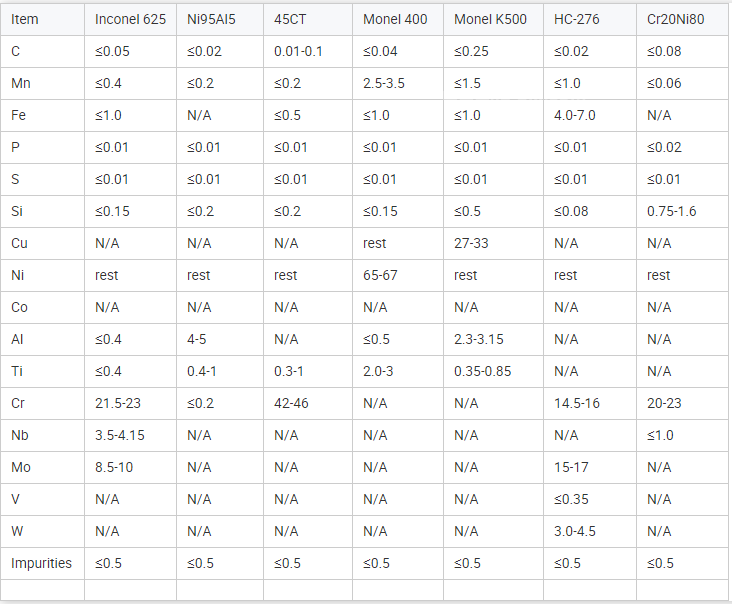

Thermal spray wire series: Inconel 625, 45CT, Ni95Al5, Monel 400, Monel K500, Hastelloy C276,Cr20Ni80

Features:

High mechanical properties

High corrosion resistance

High temperature coefficient of electrical resistance

Applications:

—For vacuum coating

—For making valves grid, inner components of vacuum valves

—Components insides the electron tubes

—For making lead, supporting wire

—For Electronic components

—For battery production

—Strong base of the filter

—manufacture of connections for heating elements as well as heating spirals in spark-plugs

FAQ – HC-276 Nickel Alloy Spray Wire

What is HC-276 nickel alloy spray wire used for?

HC-276 is used for thermal spray coatings to protect equipment like pumps, valves, and heat exchangers from corrosion in aggressive environments.What industries use HC-276 spray wire?

It is commonly used in industries such as chemical processing, marine, power generation, and oil & gas.What is the maximum temperature resistance of HC-276?

HC-276 can withstand temperatures up to 1250°C (2282°F).What makes HC-276 highly resistant to corrosion?

Its high nickel and molybdenum content provides excellent resistance to acids, chlorides, and other harsh chemicals.What is the minimum nickel content in HC-276 spray wire?

The nickel content is at least 57%.Can HC-276 be used in seawater environments?

Yes, HC-276 is highly resistant to corrosion in seawater, making it suitable for marine applications.What thermal spray techniques can be used with HC-276?

HC-276 is compatible with a variety of thermal spray processes, including arc spraying and flame spraying.