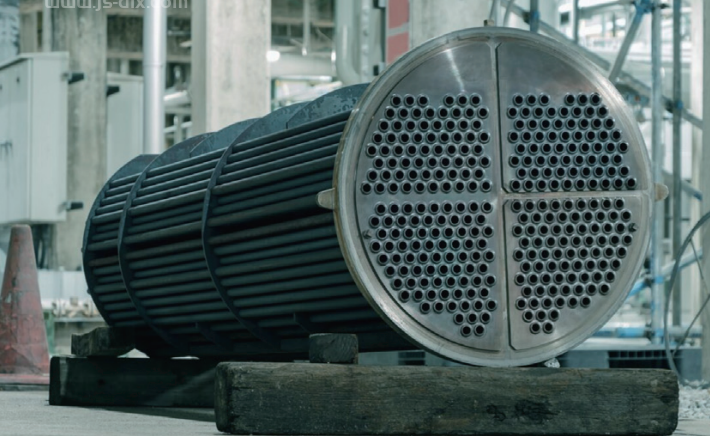

When referring to "Control Line," it typically refers to a small-diameter, high-strength, corrosion-resistant tubing used in subsea and downhole oil and gas applications, often to control subsurface safety valves or other equipment.

Differences between Super Duplex 2507 and Duplex 2205 in Control Line Applications:

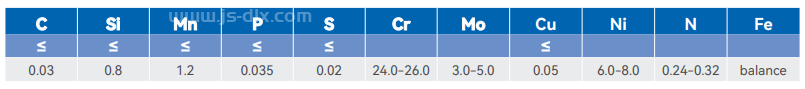

Super Duplex 2507:

Composition: It has hig

Strength: It

Corrosion Resistance: Excellent resistance to pitting and crevice corrosion in harsh environments, particularly in seawater applications.

Applications: Used in more demanding environments, like deep-sea control lines where high pressure, temperature, and chloride-induced stress cracking are concerns.

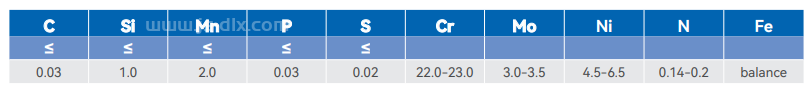

Duplex 2205:

Composition: Lower chromium, molybdenum, and nickel content than 2507.

Strength: While it still has high tensile and yield strength, it is lower than that of 2507.

Corrosion Resistance: Good corrosion resistance but less than 2507. Suitable for applications with moderate chloride exposure.

Applications: Often used in control lines for less aggressive environments compared to 2507.

Corrosion Resistance Of Different Materials(G28 A Methord)

| Grade | Rate(mm/a) |

| N08825 | ≤ 0.9 |

| N08020 | ≤ 0.5 |

| N08367 | ≤ 0.5 |

| N06625 | ≤ 0.9 |

| N10276 | ≤ 10 |

| N06200 | ≤ 1.5 |

| N06022 | ≤ 1.0 |

| N06600 | ≤ 1.0 |

| N06601 | ≤ 1.0 |

Chemical Composition

Mechanical Propertie

| Property | 2507 Mln. | 2205 Mln. | Max. |

|---|---|---|---|

| Tensile strength (psi) | 116000 | 95000 | - |

| Yield strength (psi) | 8000 | 7000 | - |

| Elongation (%) | 15 | 25 | - |

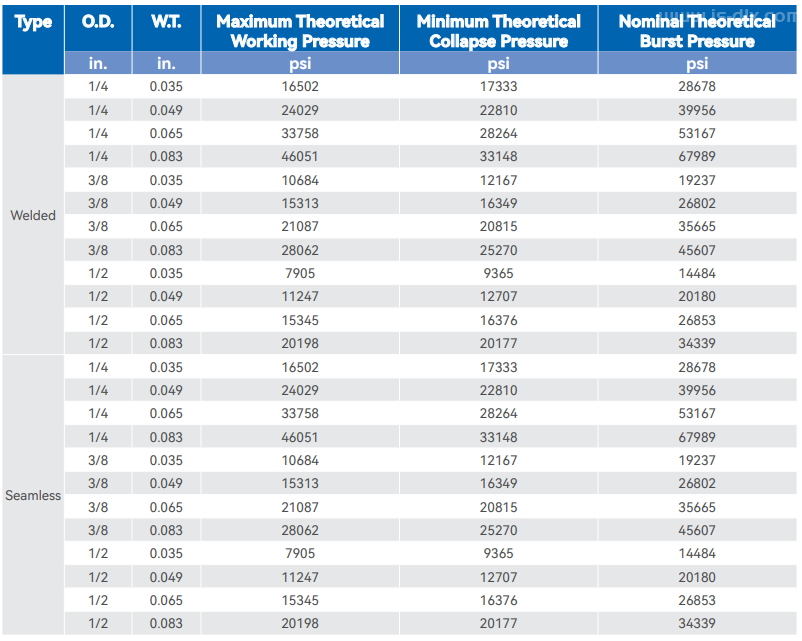

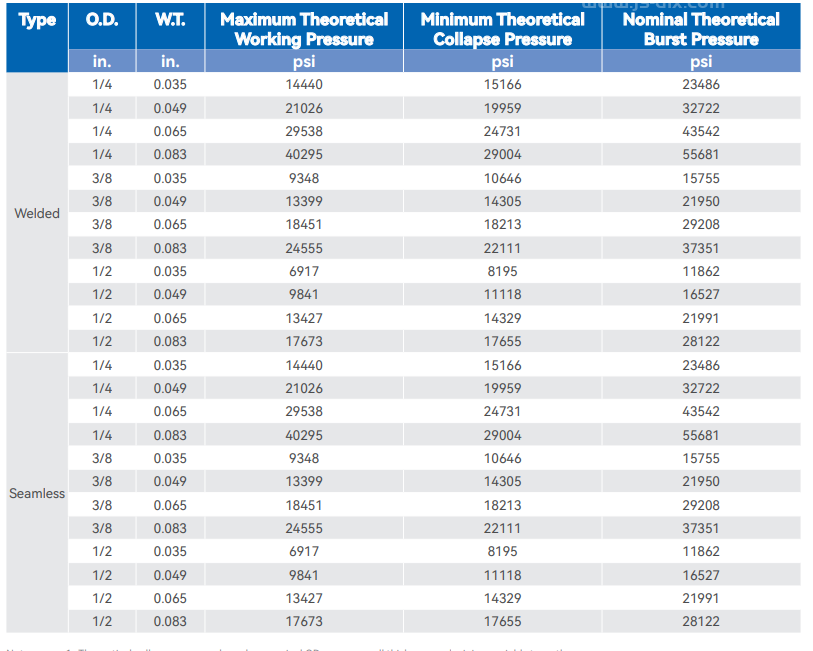

Size Dependant Characteristics (Based Upon Nominal Tubing Dimensions)

Key Benefits of Super Duplex and Duplex Control Lines:

Durability: Their high strength and corrosion resistance make them ideal for use in extreme environments, such as deepwater oil fields.

Reduced Weight: Due to the high strength-to-weight ratio, thinner walls can be used without compromising performance, reducing overall we

Cost-Effectiveness: Duplex

APPLICATION