In oil and gas applications, control lines made from Alloy 825 are employed in downhole operations for hydraulic control, chemical injection, and signal transmission. They are often chosen for environments with high pressures, temperatures, and corrosive elements like hydrogen sulfide (H₂S) and carbon dioxide (CO₂). Alloy 825 provides a balance of strength, flexibility, and resistance to sour gas corrosion, making it an ideal choice for downhole tubing in offshore and onshore oil fields.

Alloy 825 (UNS N08825) is a nickel-iron-chromium alloy with additions of molybdenum, copper, and titanium. It is designed to provide excellent resistance to both reducing and oxidizing acids, stress-corrosion cracking, and localized attack such as pitting and crevice corrosion. Due to its superior corrosion resistance and strength, Alloy 825 is widely used in harsh environments, including oil and gas applications.

Corrosion Resistance Of Different Materials(G28 A Methord)

| Grade | Rate(mm/a) |

| N08825 | ≤ 0.9 |

| N08020 | ≤ 0.5 |

| N08367 | ≤ 0.5 |

| N06625 | ≤ 0.9 |

| N10276 | ≤ 10 |

| N06200 | ≤ 1.5 |

| N06022 | ≤ 1.0 |

| N06600 | ≤ 1.0 |

| N06601 | ≤ 1.0 |

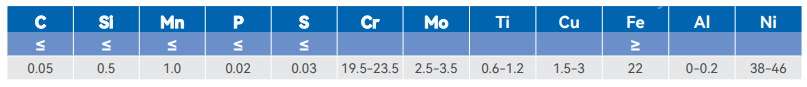

825 825E Chemical Composition

Mechanical Propertie

| Property | 825 Mln. | 825E Mln. | Max. |

|---|---|---|---|

| Tensile strength (psi) | 85000 | 95000 | - |

| Yield strength (psi) | 35000 | 60000 | - |

| Elongation (%) | 30 | 18 | - |

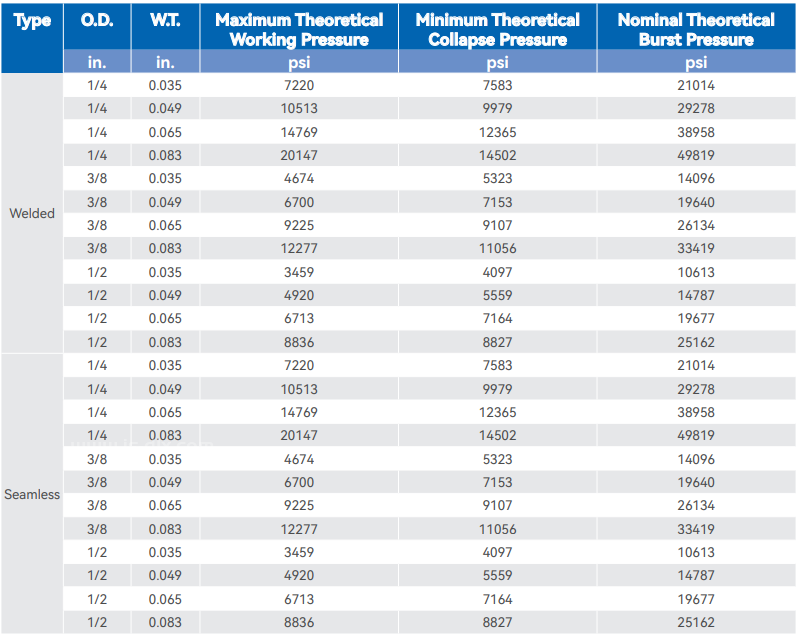

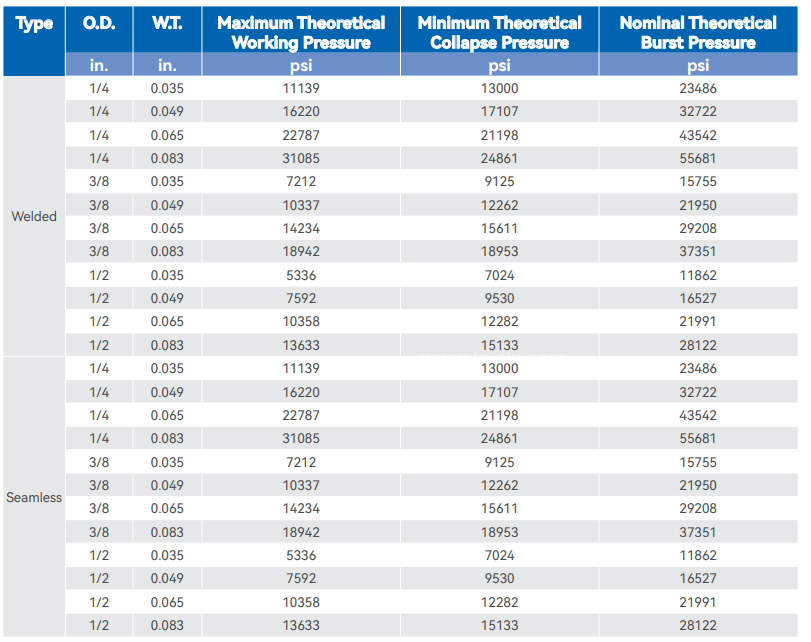

Size Dependant Characteristics (Based Upon Nominal Tubing Dimensions)

Key Properties of Alloy 825:

Corrosion Resistance: Excellent resistance to a wide range of corrosive environments, especially sulfuric acid, phosphoric acid, and seawater. It also resists stress-corrosion cracking, making it suitable for environments with high levels of chloride.

High Strength and Durability: The alloy exhibits good mechanical properties at both room temperature and elevated temperatures up to about 538°C (1000°F).

Oxidation Resistance: Good resistance to oxidation and scaling at elevated temperatures.

Localized Corrosion Resistance: The molybdenum and copper in Alloy 825 provide resistance to reducing environments, while chromium enhances resistance to oxidizing conditions.

APPLICATION

Key Properties:

Oil and Gas Control Lines: Alloy 825 is used in control line tubing in oil and gas applications, particularly for downhole systems exposed to corrosive environments with high chloride concentrations, acids, or sour gas. These control lines deliver hydraulic control, transmit pressure signals, or inject chemicals.

Chemical Processing: Used in chemical processing industries where sulfuric acid, phosphoric acid, and other corrosive agents are present.

Nuclear Fuel Reprocessing: The alloy is resistant to nitric acid and other radioactive environments, making it suitable for nuclear fuel reprocessing.

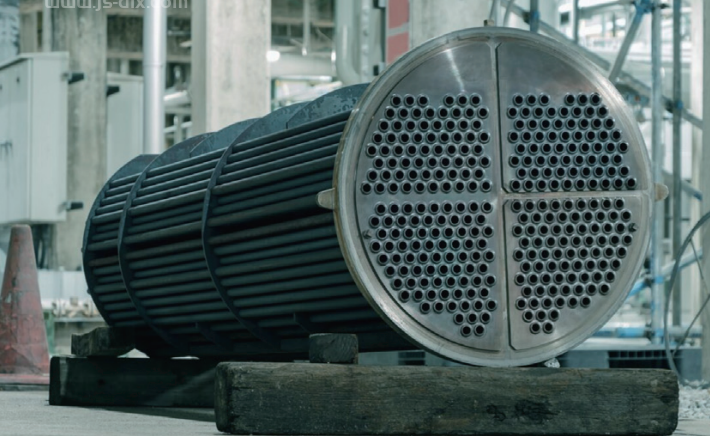

Heat Exchangers and Piping: Ideal for heat exchangers, piping, and tanks exposed to seawater or industrial chemicals.