Product Description

The adaptability of Nitinol allows for the creation of advanced orthopedic implants that respond to the body’s movements. This functionality enhances patient mobility and comfort, making recovery after surgery more manageable.

Applications

Surgical Instruments

Used in a variety of surgical tools and devices for enhanced functionality.Stents for Blood Vessels

Essential in the development of stents to keep arteries and veins open.Implants in Dentistry

Employed in dental implants to ensure better fit and comfort for patients.Instruments for Minimally Invasive Techniques

Utilized in equipment designed for less invasive surgical interventions.Scaffolding in Tissue Regeneration

Serves as a framework in tissue engineering applications to support cell growth.Prosthetic Joints

Incorporated into prosthetic joints for improved mechanical performance.Orthopedic Fixation Devices

Utilized in the production of devices that stabilize broken bones.Sensors for Biological Applications

Integrated into biosensing technologies to enhance detection capabilities.Thermal Sensing Devices

Used in devices that respond to temperature changes for various applications.Surgical Closure Devices

Employed in fasteners that secure tissues during surgical procedures.

Advantages

Exceptional Elasticity

Capable of reverting to its initial shape after substantial deformation.Compatibility with Biological Systems

Demonstrates high compatibility with living tissue, reducing the risk of rejection.Resistance to Corrosion

Offers durability in bodily fluids, ensuring long-term functionality.Weight Efficiency

Lightweight properties make medical devices more manageable for patients.Responsive to Temperature Changes

Can alter its shape based on temperature, suitable for innovative medical uses.Remarkable Strength

Provides high tensile strength, allowing it to endure significant stress.Adaptability

Its flexible nature enables ease of use in intricate surgical procedures.Longevity

Maintains effectiveness over extended periods, even with repetitive use.Precision Engineering

Allows for exact movements and placements in delicate medical applications.Minimally Invasive Options

Promotes less invasive surgical techniques, leading to faster patient recovery.

Detailed Photos

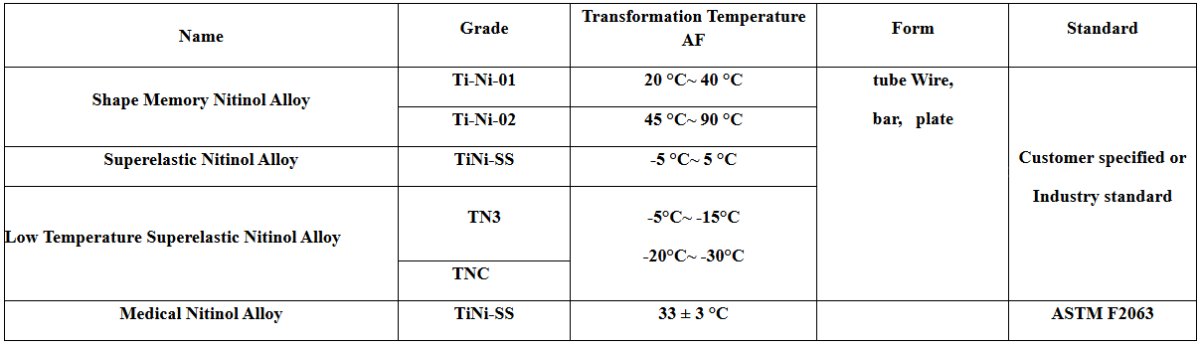

Product Parameters

Recommended products

Company Profile

Our company Principle is " Quality first, Customer first".

CHANGZHOU DLX ALLOY CO, LTD was established in 2002 and has got Iso9001 International Quality Management System Certificate and SGS Certificate. Our factory is professional in researching and producing special alloy material. From melting, drawing, heat treatment, finishing and testing .We offer nickel-based, copper-based, and iron-based alloys, including super alloy, welding materials, anti-corrosion alloy, precision alloy, FeCrAl alloy, NiCr alloy, CuNi alloy, thermocouple and etc, in the form of wire, strip, ribbon, bar, tube, plate.

If any requirements and questions, please feel free to reach:

Sophie Wang | Sales +86 13275217619

International Sales Depart.

Jiangsu Victory Technology Co., Ltd

A: NO.32 West Taihu Road, Xinbei District, Changzhou, Jiangsu

FAQ

Oct.1-7 and Chinese New Year holiday . Pls email us during our holiday if u have any question.

Do you provide free samples?

Yes,we can provide a free sample for testing,buyer should bear all the shipping costs.

What is your payment terms?

T/T,L/C,D/A,D/P,Western Union,MoneyGram,Paypal

What is the lead time?

Usually sample lead time is 7 days after payment has been confirmed.