Product Description

Nitinol plates are marvels of material engineering, exhibiting a rare combination of superelasticity and shape memory. These nickel-titanium alloy plates can undergo extreme deformations of up to 8% strain and then fully recover their original shape, making them incredibly resistant to fatigue and impact. Their uncanny ability to "remember" a pre-defined form and revert to it when exposed to specific temperatures unlocks a world of possibilities for adaptive, responsive, and morphing structures.

Applications

Here are the 6 main application areas for Nitinol plates:

1. Aerospace Applications:

- Deployable and retractable satellite antennas and solar panels

- Adaptive wing and tail designs

- Aircraft structural components and brackets

2. Medical Device Applications:

- Expandable stents and support structures

- Foldable and adjustable prosthetics and orthotic devices

- Surgical instruments and implantable materials

3. Automotive and Transportation Applications:

- Shock absorbing and vibration damping systems

- Adaptive body structures and components

- Wheel hubs and suspension systems

4. Architecture and Infrastructure Applications:

- Adaptive shading and facade systems

- Adjustable piping and conduit

- Seismic and fire safety devices

5. Energy and Industrial Applications:

- Critical components for marine energy generation equipment

- Sensors for high-temperature and corrosive environments

- Damping and vibration-absorbing elements for industrial machinery

6. Consumer Electronics and Smart Devices Applications:

- Foldable and expandable screens and displays

- Adaptive wearable and body-conforming technologies

- Smart accessories with shape memory capabilities

These application areas showcase the diverse utility of Nitinol plates, spanning from aerospace and medical devices to automotive, construction, industrial,

and consumer electronics sectors. The material's exceptional mechanical properties, adaptability, and corrosion resistance enable it to excel in a wide range of advanced engineering challenges.

Detailed Photos

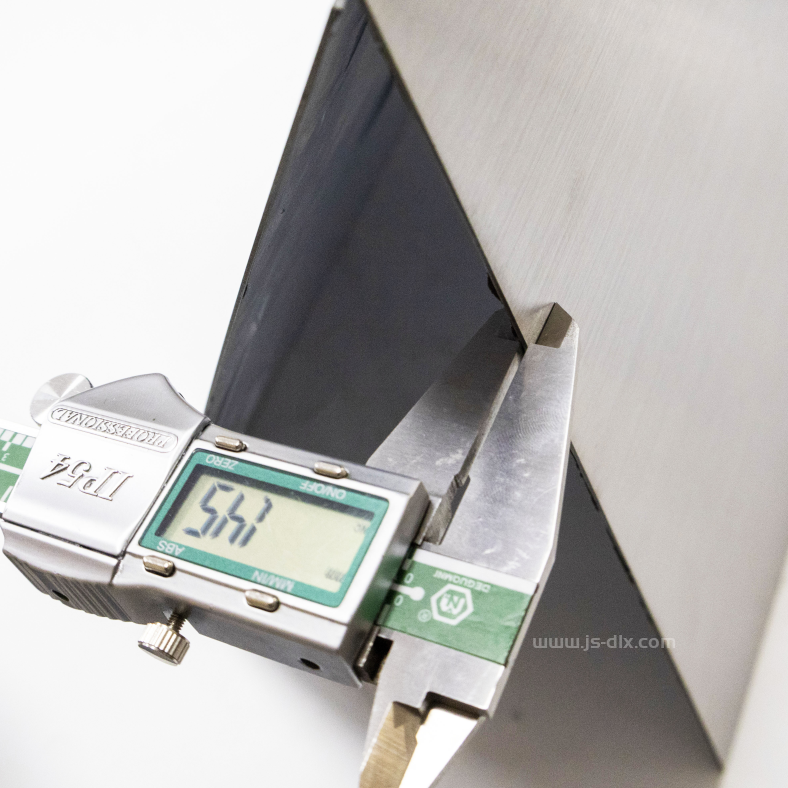

Bright surface

Precise size

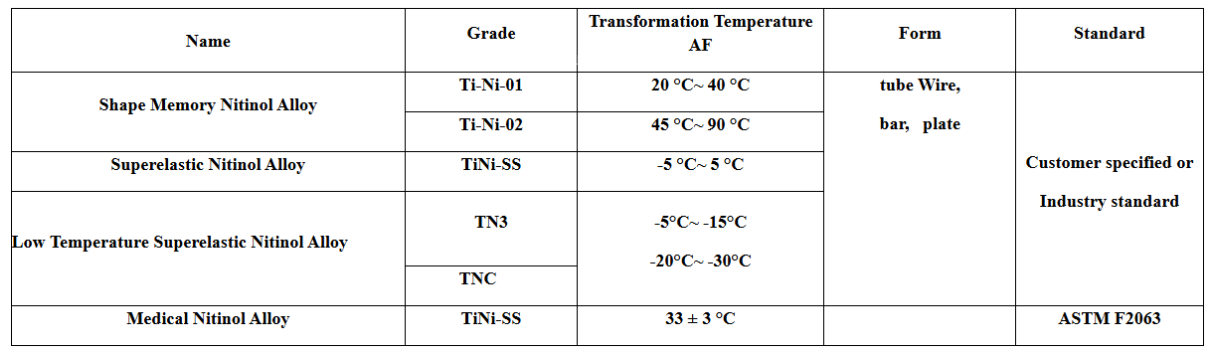

Product Parameters

Description of the typical composition of Nitinol plates:

Nitinol plates are primarily composed of nickel and titanium, with the nickel content typically ranging from 50% to 56% and the titanium content ranging from 44% to 50%. This near-equiatomic ratio of nickel to titanium is what gives Nitinol its signature shape memory and superelastic properties.

The precise nickel-to-titanium composition of Nitinol plates can be adjusted based on the specific performance requirements of the application. Common Nitinol plate compositions include:

- 55% Nickel - 45% Titanium

- 50.8% Nickel - 49.2% Titanium

By carefully controlling the alloy composition and implementing precise heat treatment processes,

the transformation temperatures, strength, ductility, and other key characteristics of the Nitinol plates can be optimized to meet the needs of diverse industries,

from aerospace and medical devices to automotive and consumer electronics.

In some cases, small amounts of additional elements like copper, iron, or aluminum may be alloyed with the nickel and titanium to further enhance specific properties.

However, the nickel and titanium remain the principal and defining components of Nitinol plates, accounting for the vast majority of the material's composition.

The exceptional combination of properties exhibited by Nitinol plates, derived from their carefully engineered chemical composition,

has made them an increasingly valuable and versatile material in a wide range of advanced engineering applications.

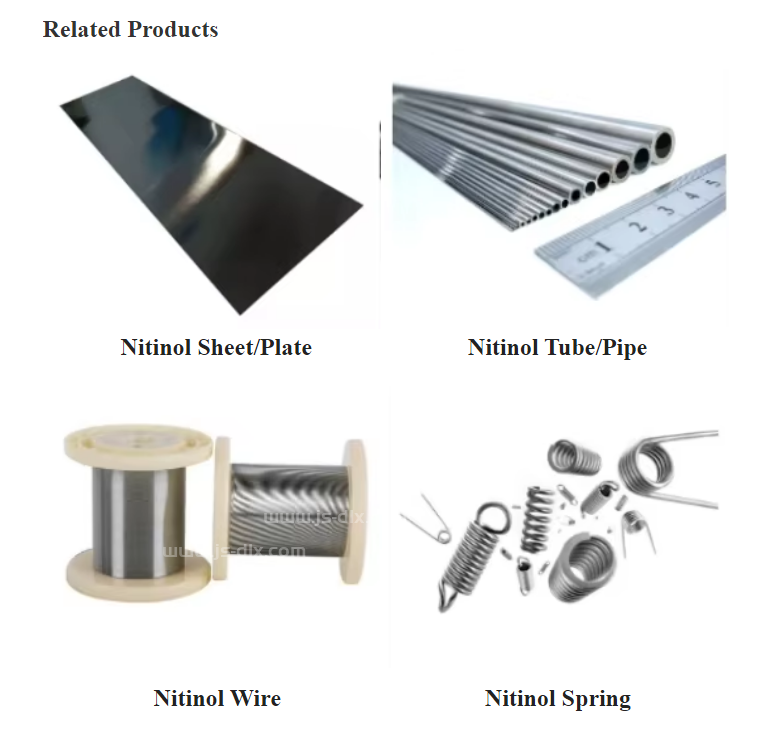

Recommended products

Company Profile

Our company Principle is " Quality first, Customer first".

CHANGZHOU DLX ALLOY CO, LTD was established in 2002 and has got Iso9001 International Quality Management System Certificate and SGS Certificate. Our factory is professional in researching and producing special alloy material. From melting, drawing, heat treatment, finishing and testing .We offer nickel-based, copper-based, and iron-based alloys, including super alloy, welding materials, anti-corrosion alloy, precision alloy, FeCrAl alloy, NiCr alloy, CuNi alloy, thermocouple and etc, in the form of wire, strip, ribbon, bar, tube, plate.

If any requirements and questions, please feel free to reach:

Sophie Wang | Sales +86 13275217619

International Sales Depart.

Jiangsu Victory Technology Co., Ltd

A: NO.32 West Taihu Road, Xinbei District, Changzhou, Jiangsu

FAQ

Oct.1-7 and Chinese New Year holiday . Pls email us during our holiday if u have any question.

Do you provide free samples?

Yes,we can provide a free sample for testing,buyer should bear all the shipping costs.

What is your payment terms?

T/T,L/C,D/A,D/P,Western Union,MoneyGram,Paypal

What is the lead time?

Usually sample lead time is 7 days after payment has been confirmed.