Product Description

Engineered for demanding environments, Nitinol plates boast exceptional corrosion resistance that allows them to reliably operate in harsh conditions. From offshore renewable energy systems battling saltwater exposure to medical implants requiring biocompatibility, these versatile plates can be tailored to withstand the toughest challenges. Leveraging their superb mechanical properties and customizable capabilities, Nitinol plates are transforming the landscape of advanced engineering.

Applications

1. Aerospace Industry: Nitinol plates are widely used in various components and structures in the aerospace industry,

such as aircraft hydraulic line connectors and spacecraft structural elements, due to their excellent corrosion resistance, high-temperature tolerance, and shape memory effect.

These critical components require high strength and reliability in harsh environments.

2. Medical Devices: Nitinol Materials' excellent biocompatibility and superelasticity make them widely used in the manufacture of various medical implants and surgical instruments,

such as orthopedic stents, vascular stents, dental orthodontic wires, and surgical clamps.

These devices need to function reliably within the human body without causing rejection.

3. Automotive Industry: Leveraging the exceptional shape memory characteristics and corrosion resistance of Nitinol alloys,

the automotive industry utilizes them in a variety of applications, including car door locks, airbag release mechanisms, and engine thermostats.

These components must maintain stable and reliable performance in harsh environments.

4. Consumer Electronics: Nitinol plates find numerous applications in consumer electronic products,

such as vehicle navigation system antennas, mobile phone antennas, and flexible structural components in laptops, cameras, and other devices.

Their superior mechanical properties and fatigue resistance meet the usage requirements of consumer electronics.

5. Industrial Automation: Nitinol materials can be used to manufacture robotic joints, sensors, and actuators in industrial automation equipment,

utilizing their shape memory and superelastic properties to achieve precise positioning and flexible motion control.

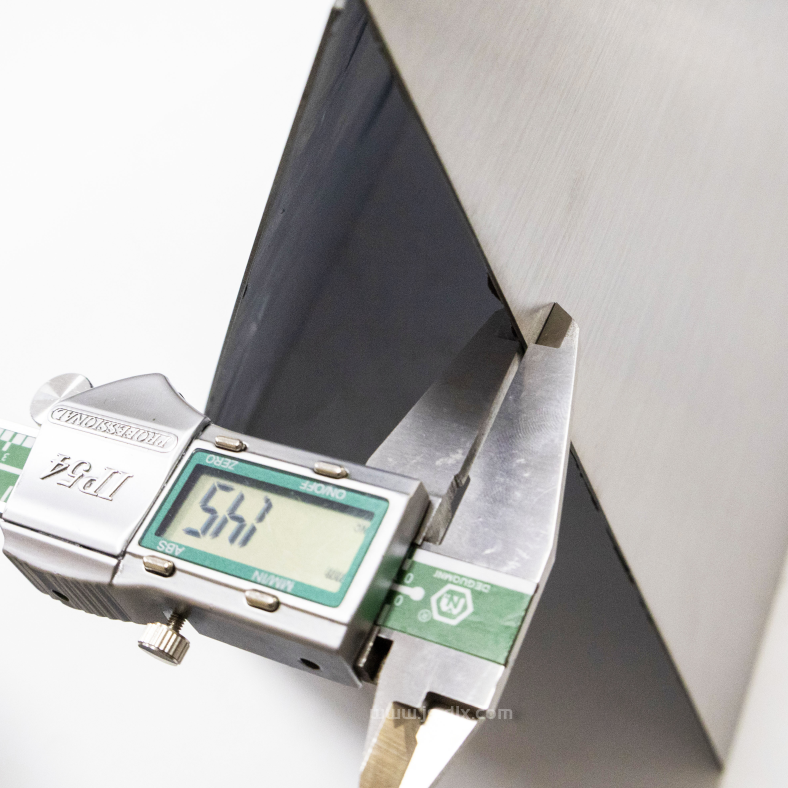

Detailed Photos

Bright surface

Precise size

Complete package

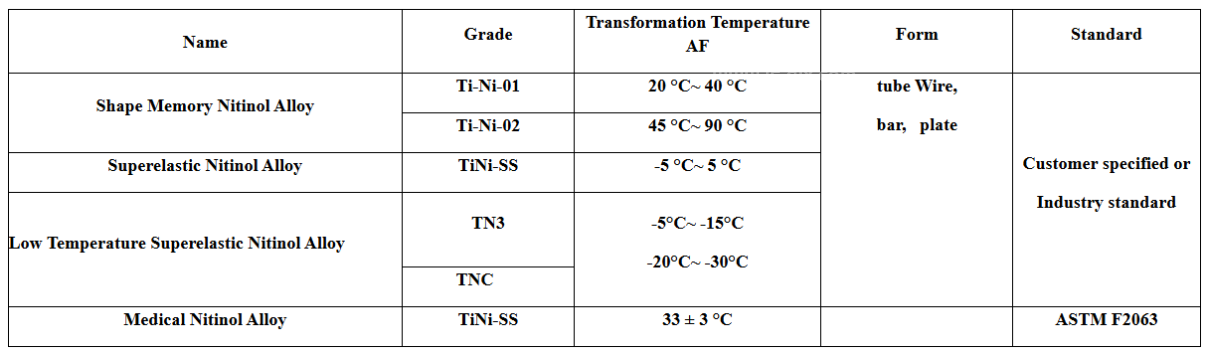

Product Parameters

Nitinol plates are an advanced alloy material primarily composed of two key metallic elements - nickel, which makes up 50-56% of the overall composition, and titanium, accounting for 44-50%. This near-equiatomic ratio between the nickel and titanium components is the foundation of Nitinol's renowned shape memory and superelastic properties. By carefully adjusting the precise proportions of the nickel and titanium, often fine-tuned to 55% nickel paired with 45% titanium or 50.8% nickel paired with 49.2% titanium, engineers can optimize the transformation temperatures, strength, and other critical performance characteristics of the Nitinol plates to meet the specific requirements of a wide range of applications. In some specialized cases, small amounts of additional alloying elements such as copper, iron, or aluminum may be introduced to enhance particular attributes. However, the nickel and titanium remain the dominant and defining constituents that endow Nitinol plates with their exceptional capabilities across diverse industries, from aerospace and medical devices to automotive and consumer electronics.

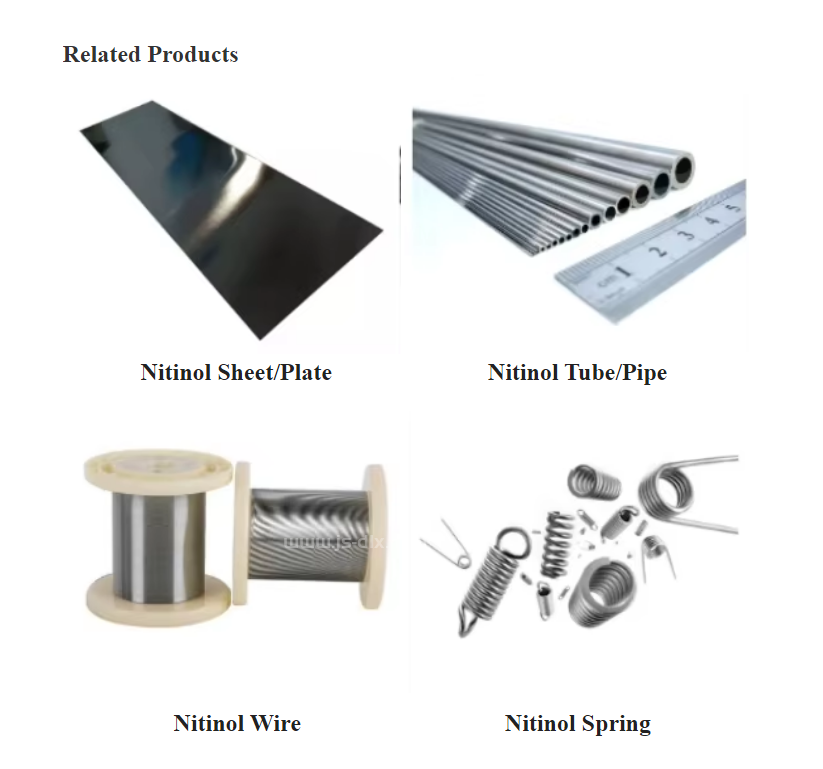

Recommended products

Company Profile

Our company Principle is " Quality first, Customer first".

CHANGZHOU DLX ALLOY CO, LTD was established in 2002 and has got Iso9001 International Quality Management System Certificate and SGS Certificate. Our factory is professional in researching and producing special alloy material. From melting, drawing, heat treatment, finishing and testing .We offer nickel-based, copper-based, and iron-based alloys, including super alloy, welding materials, anti-corrosion alloy, precision alloy, FeCrAl alloy, NiCr alloy, CuNi alloy, thermocouple and etc, in the form of wire, strip, ribbon, bar, tube, plate.

If any requirements and questions, please feel free to reach:

Sophie Wang | Sales +86 13275217619

International Sales Depart.

Jiangsu Victory Technology Co., Ltd

A: NO.32 West Taihu Road, Xinbei District, Changzhou, Jiangsu

FAQ

Oct.1-7 and Chinese New Year holiday . Pls email us during our holiday if u have any question.

Do you provide free samples?

Yes,we can provide a free sample for testing,buyer should bear all the shipping costs.

What is your payment terms?

T/T,L/C,D/A,D/P,Western Union,MoneyGram,Paypal

What is the lead time?

Usually sample lead time is 7 days after payment has been confirmed.