Product Description

The unique shape memory effect of nickel-titanium (nitinol) alloy sheets enables them to adapt to their surroundings in remarkable ways.

These sheets can be programmed to change shape in response to changes in temperature, allowing them to be used in smart structures, actuators, and adaptive systems.

Their responsiveness, combined with their high strength-to-weight ratio and fatigue resistance, make Nitinol Sheets a valuable material for aerospace, robotics, and biomedical applications where dynamic behavior and reliable performance are essential.

Applications

Characteristics:

1. Thermal Adaptability:

- Nitinol sheets can be engineered to undergo phase transformations at specific temperature thresholds.

- This thermal responsiveness allows for the development of self-regulating systems and devices that can automatically adapt to environmental conditions.

2. Mechanical Resilience:

- Nitinol sheets exhibit exceptional resistance to mechanical fatigue, enabling them to withstand millions of loading cycles without failure.

- This property is crucial for applications that require durable and long-lasting performance.

3. Precise Shapability:

- Nitinol sheets can be easily formed, bent, and shaped into complex geometries using various manufacturing techniques.

- This allows designers to create customized solutions that closely match the requirements of their applications.

4. Electrical Conductivity:

- Certain types of nitinol sheets possess good electrical conductivity, enabling their use in applications that require the transfer of electrical signals or energy.

- This characteristic opens up opportunities for integrating nitinol into smart and interactive systems.

Advantages:

1. Adaptive Functionality:

- The thermal responsiveness of nitinol sheets can be leveraged to create self-adjusting and self-regulating devices that can autonomously adapt to changing environmental conditions.

- This adaptability can lead to improved efficiency, reliability, and user experience in various applications.

2. Space and Weight Savings:

- The unique shape memory and superelastic properties of nitinol sheets can enable the design of compact and lightweight components.

- This advantage is particularly valuable in applications where size and weight are critical factors, such as aerospace and portable electronics.

3. Reduced Manufacturing Complexity:

- Nitinol sheets can often simplify the design and manufacturing of certain components and devices by eliminating the need for complex assemblies or additional mechanisms.

- This can lead to cost savings and streamlined production processes.

4. Expanded Design Possibilities:

- The versatile nature of nitinol sheets, in terms of their shapability and responsiveness, allows designers to explore novel and innovative solutions that were previously not feasible with traditional materials.

- This can drive the development of groundbreaking products and technologies across multiple industries.

By leveraging these distinctive characteristics and advantages, engineers and designers can unlock the full potential of nitinol sheets and push the boundaries of what is possible in their respective fields.

Detailed Photos

Lustrous Appearance:

Nitinol sheets produced through advanced manufacturing processes exhibit a remarkably lustrous and polished surface finish.

This eye-catching appearance is achieved through the precise control of production parameters, ensuring a uniform and consistent sheen across the entire surface of the sheets.

The lustrous quality not only enhances the aesthetic appeal of nitinol but also contributes to its exceptional corrosion resistance,

as the smooth surface minimizes the likelihood of pitting and discoloration over time.

Dimensional Precision:

Nitinol sheets are manufactured to exacting dimensional specifications, guaranteeing a high degree of size accuracy and consistency.

The thickness, width, and length of these sheets can be meticulously tailored and maintained within tight tolerances, making them suitable for applications that demand stringent dimensional requirements. This precision in size allows for the seamless integration of nitinol components into complex assemblies and structures, enabling engineers to design with unwavering confidence.

Comprehensive Safeguarding:

Nitinol sheets are meticulously packaged to safeguard their pristine condition during transportation and storage.

The sheets are carefully wrapped in protective materials, such as anti-tarnish paper or plastic, to prevent any surface scratches or contamination.

The packaging also includes detailed labeling and comprehensive documentation, providing critical information about the material's specifications, lot numbers, and traceability.

This comprehensive packaging approach ensures that the nitinol sheets maintain their exceptional quality and performance characteristics throughout the supply chain.

By combining these features of lustrous appearance, dimensional precision, and comprehensive safeguarding,

nitinol sheet suppliers offer a high-quality product that meets the demanding requirements of various industries, from medical devices to aerospace components.

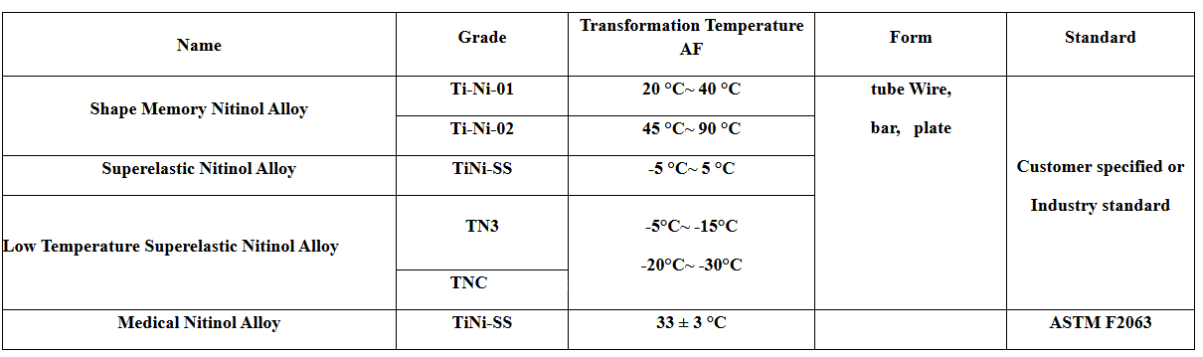

Product Parameters

Nickel-Titanium (Nitinol) Alloy Composition and Key Characteristics

Nickel-Titanium (Nitinol) Alloy Composition:

Nitinol is a binary alloy composed primarily of nickel (Ni) and titanium (Ti). The typical composition of nitinol is around 50-60% nickel and 40-50% titanium,

with the exact percentages varying depending on the specific application and desired properties.

Key Characteristics of Nitinol Alloy Composition:

1. Equiatomic Composition:

- The optimal nitinol composition is often close to an equiatomic ratio, meaning the atomic percentages of nickel and titanium are approximately equal.

- This equiatomic composition is critical for achieving the unique shape memory and superelastic properties that make nitinol a versatile material.

2. Precise Nickel-Titanium Ratio:

- Slight variations in the nickel-to-titanium ratio can significantly impact the alloy's characteristics, such as the transformation temperatures, strength, and ductility.

- Manufacturers carefully control the composition to obtain the desired properties for specific applications.

3. Microstructural Stability:

- The equiatomic composition of nitinol contributes to its excellent microstructural stability, ensuring the alloy maintains its unique properties over time and under various operating conditions.

- This stability is crucial for ensuring the long-term reliability and performance of nitinol-based components and devices.

4. Tailored Properties:

- By adjusting the nickel-titanium ratio, manufacturers can fine-tune the characteristics of nitinol, such as its transformation temperatures, mechanical strength, and corrosion resistance.

- This flexibility allows for the optimization of nitinol's properties to match the specific requirements of different applications.

The careful control of the nitinol composition, particularly the nickel-to-titanium ratio, is a critical factor in unlocking the full potential of this remarkable alloy.

The unique properties and performance advantages of nitinol stem from this precisely engineered composition, making it a versatile material for a wide range of industries,

from medical to aerospace and beyond.

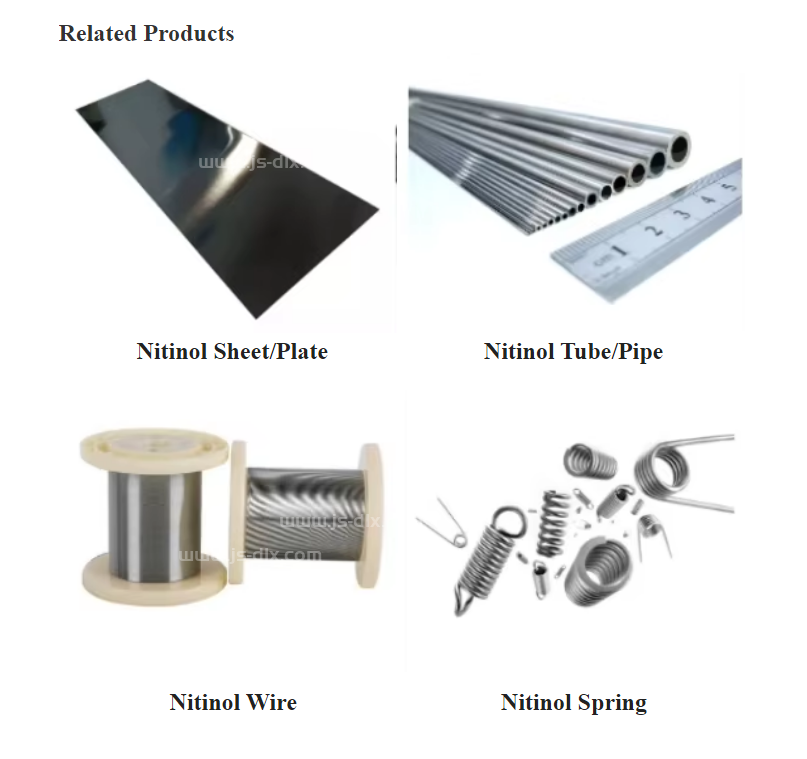

Recommended Products

Company Profile

Our company Principle is " Quality first, Customer first".

CHANGZHOU DLX ALLOY CO, LTD was established in 2002 and has got Iso9001 International Quality Management System Certificate and SGS Certificate. Our factory is professional in researching and producing special alloy material. From melting, drawing, heat treatment, finishing and testing .We offer nickel-based, copper-based, and iron-based alloys, including super alloy, welding materials, anti-corrosion alloy, precision alloy, FeCrAl alloy, NiCr alloy, CuNi alloy, thermocouple and etc, in the form of wire, strip, ribbon, bar, tube, plate.

If any requirements and questions, please feel free to reach:

Sophie Wang | Sales +86 13275217619

International Sales Depart.

Jiangsu Victory Technology Co., Ltd

A: NO.32 West Taihu Road, Xinbei District, Changzhou, Jiangsu

FAQ

Oct.1-7 and Chinese New Year holiday . Pls email us during our holiday if u have any question.

Do you provide free samples?

Yes,we can provide a free sample for testing,buyer should bear all the shipping costs.

What is your payment terms?

T/T,L/C,D/A,D/P,Western Union,MoneyGram,Paypal

What is the lead time?

Usually sample lead time is 7 days after payment has been confirmed.