Product Description

Forged in the crucible of innovation, the Nitinol Rod stands as a testament to the ingenuity of humankind. Its cylindrical form, a meticulously crafted canvas, plays host to a symphony of properties that defy convention. From the whisper-soft caress of its superelastic nature to the unwavering resilience that defies the passage of time, this alloy marvel embodies the very essence of adaptability. Like a chameleon shifting its hue, the nitinol rod can be tailored to the precise needs of its domain, be it the delicate mechanisms of medical devices or the unyielding demands of aerospace engineering. In its very essence, this metallic marvel represents the triumph of human imagination, a testament to our ability to harness the power of the elements and mold them into solutions that propel us ever forward.

Applications

Nitinol Tubes: Engineered for Exceptional Performance

Pioneering Nitinol Alloy Tubing:

Crafted from a meticulously designed nickel-titanium alloy, nitinol tubes offer an unparalleled combination of advanced properties and versatile applications.

Unrivaled Flexibility and Resilience:

- The unique composition of these tubes endows them with a remarkable shape memory effect, allowing them to recover their original form after substantial deformation.

- Their exceptional superelastic characteristics enable them to withstand significant bending and compression without permanent damage, ensuring reliable performance in demanding environments.

Exceptional Strength and Lightweight:

- Nitinol tubes exhibit an outstanding strength-to-weight ratio, combining remarkable strength with a lightweight design.

- The material's inherent flexibility and durability make it an ideal choice for applications where both strength and flexibility are required.

Corrosion-Resistant and Biocompatible:

- The nitinol alloy provides superior resistance to corrosion, ensuring the long-term integrity and performance of the tubes.

- Additionally, the biocompatible nature of the material allows these tubes to be safely used in medical devices and implants, opening up a wide range of innovative healthcare applications.

Precision Engineering and Quality Assurance:

- Nitinol tubes are manufactured to exacting dimensional tolerances, enabling seamless integration into diverse products and systems.

- Rigorous quality control measures guarantee the consistency and reliability of our nitinol tube offerings, ensuring customer satisfaction.

Boundless Application Potential:

- The unique properties of nitinol tubes make them versatile and suitable for a wide range of applications, including medical devices, aerospace components, automotive parts, and industrial equipment.

- Innovative engineers and designers can harness the transformative potential of these advanced tubes to create pioneering solutions.

Trusted Partner for Exceptional Quality:

- Customers can rely on the exceptional quality and performance of our nitinol tubes, backed by our commitment to excellence.

- Secure packaging and reliable delivery ensure the safe and efficient supply of these precision-engineered components.

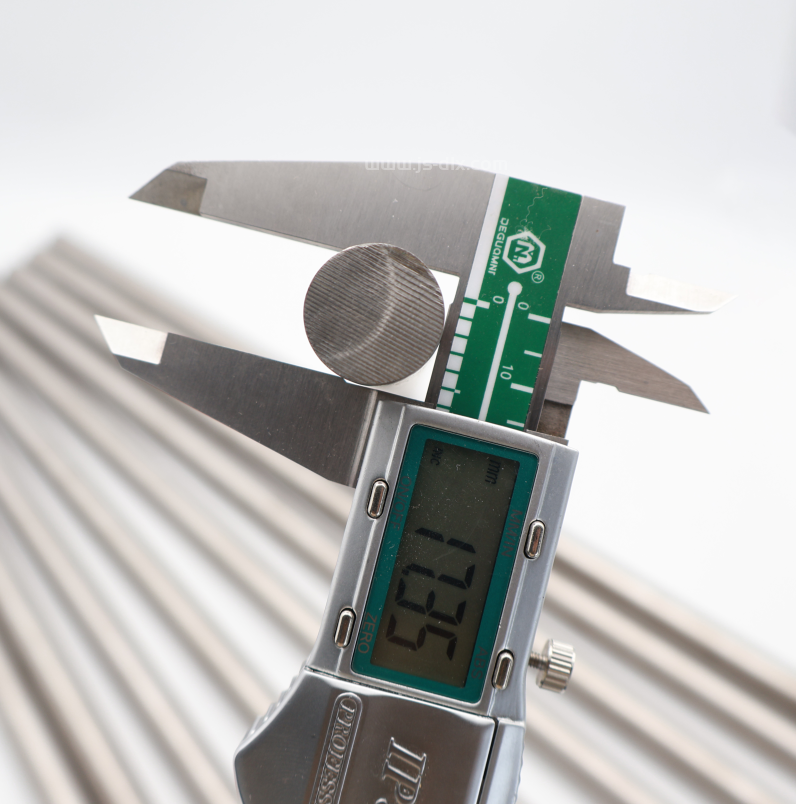

Detailed Photos

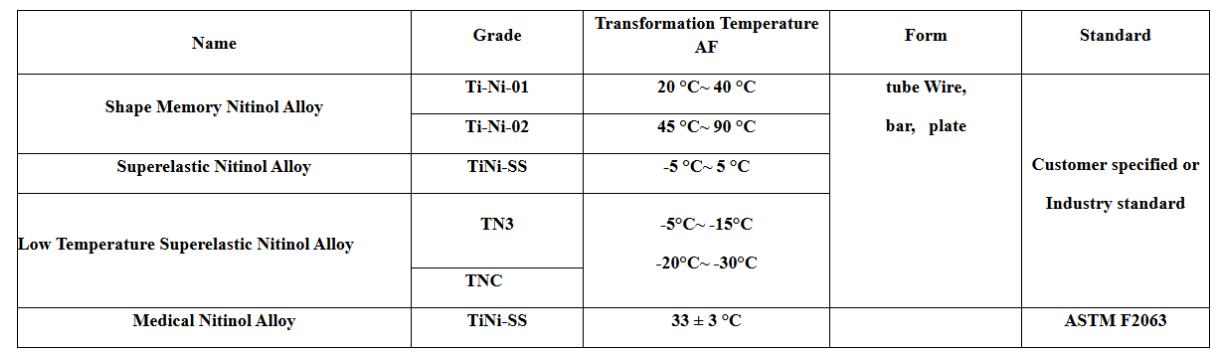

Product Parameters

The Nitinol Alloy: A Smart Combination of Nickel and Titanium

Nitinol Composition

Nitinol is an alloy primarily made up of nickel and titanium. The precise balance between these two key elements is the driving force behind the material's exceptional properties.

Nickel's Role

Nickel is the dominant component, typically accounting for 50-60% of the nitinol alloy. This significant nickel presence is the foundation of the material's shape memory and superelastic characteristics.

Titanium's Contribution

While nickel is the primary element, titanium plays a crucial supporting role, making up 40-50% of the alloy. Titanium's inclusion adds strength, corrosion resistance, and biocompatibility to the material.

-Engineered Synergy

The specific nickel-to-titanium ratio is the result of extensive research. This carefully balanced composition is the key to the material's unparalleled combination of advanced properties.

-Manufacturing Excellence

Maintaining the optimal nickel-titanium ratio is essential for ensuring the consistent performance and reliability of nitinol products. Our rigorous manufacturing and quality control measures guarantee the exceptional quality of our nitinol offerings.

-Transformative Potential

The unique blend of nickel and titanium in nitinol unlocks its transformative potential, making it a highly sought-after material. By harnessing the power of this versatile alloy, we can revolutionize innovative projects and unlock boundless possibilities.

Recommended Products

Company Profile

Our company Principle is " Quality first, Customer first".

CHANGZHOU DLX ALLOY CO, LTD was established in 2002 and has got Iso9001 International Quality Management System Certificate and SGS Certificate. Our factory is professional in researching and producing special alloy material. From melting, drawing, heat treatment, finishing and testing .We offer nickel-based, copper-based, and iron-based alloys, including super alloy, welding materials, anti-corrosion alloy, precision alloy, FeCrAl alloy, NiCr alloy, CuNi alloy, thermocouple and etc, in the form of wire, strip, ribbon, bar, tube, plate.

If any requirements and questions, please feel free to reach:

Sophie Wang | Sales +86 13275217619

International Sales Depart.

Jiangsu Victory Technology Co., Ltd

A: NO.32 West Taihu Road, Xinbei District, Changzhou, Jiangsu

FAQ

Oct.1-7 and Chinese New Year holiday . Pls email us during our holiday if u have any question.

Do you provide free samples?

Yes,we can provide a free sample for testing,buyer should bear all the shipping costs.

What is your payment terms?

T/T,L/C,D/A,D/P,Western Union,MoneyGram,Paypal

What is the lead time?

Usually sample lead time is 7 days after payment has been confirmed.