Product Description

Nitinol Tubes

Nickel Titanium (Nitinol) tubes are a specialized metal tubing with unique shape memory and superelastic properties. They offer high strength, corrosion resistance, and fatigue/wear durability.

These tubes are used in various applications, including medical devices, aerospace, and electronics.

The composition and manufacturing process of Nitinol tubes can be tailored to meet specific industry requirements.

Nickel Titanium (Nitinol) tubes have a wide range of applications across different industries due to their unique properties. Some of the key application areas for Nitinol tubes include:

Applications

1. Medical Applications:

- Cardiovascular stents

- Catheters and guidewires

- Orthopedic implants (e.g., bone fixation devices)

- Dental and orthodontic applications

- Surgical instruments and tools

2. Aerospace and Automotive:

- Aircraft and spacecraft components

- Actuators and sensors

- Engine and fuel system parts

- Vibration damping systems

3. Electronics and Robotics:

- Micro-electromechanical systems (MEMS)

- Flexible electronics

- Robotic joints and actuators

4. Industrial and General Engineering:

- Couplings and connectors

- Valves and flow control devices

- Springs and fasteners

- Vibration damping applications

The shape memory effect, superelasticity, and corrosion resistance of Nitinol tubes make them invaluable in a wide range of industries,

from medical and aerospace to electronics and industrial applications.

Detailed Photos

We can customize the thickness of the Nickel Titanium tubes to precisely match your specific requirements. Prior to shipment, we will provide you with detailed photographs showcasing the exact measurements, ensuring the dimensions meet your expectations. This step allows you to thoroughly review and confirm the product specifications, guaranteeing that the final item perfectly aligns with your needs.

To ensure the Nickel Titanium tubes arrive in pristine condition, we will securely package them using sturdy wooden pallets or crates. This durable packaging method effectively shields the product from any potential damage during transit, giving you the confidence and peace of mind that you will receive a high-quality product as expected.

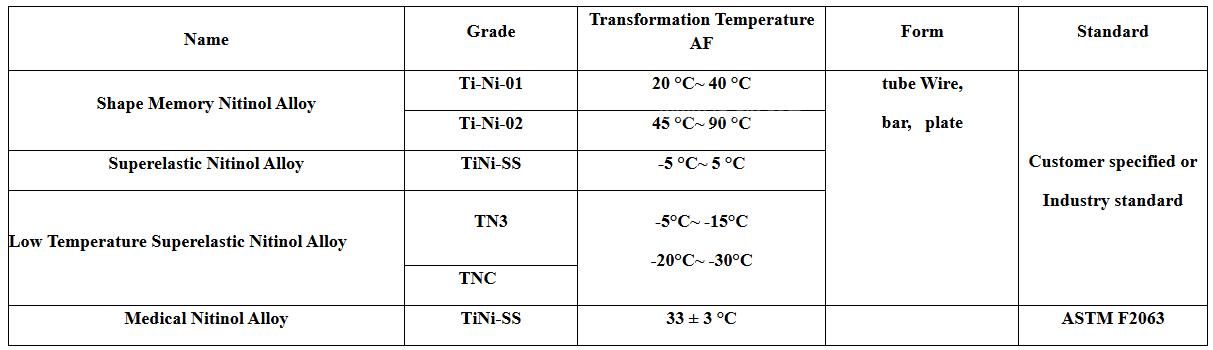

Product Parameters

Nitinol Alloy Bar Composition and Advantages

Nickel Titanium (Nitinol) alloy bars are composed of approximately 50-55% nickel and 45-50% titanium. This balanced composition gives the alloy its unique properties:

1. Shape Memory Effect:

Nitinol bars can "remember" their original shape and return to it after deformation.

This provides flexibility and self-adjusting capabilities.

2. Superelasticity:

Nitinol bars exhibit exceptional elasticity, able to undergo large deformations and quickly recover their original shape.

This offers superior flexibility, shock absorption, and impact resistance.

3. Corrosion Resistance:

The alloy's composition and protective oxide layer make it highly resistant to corrosion.

This ensures long-lasting durability, even in harsh environments.

4. Biocompatibility:

Nitinol is widely used in medical applications due to its excellent biocompatibility.

The alloy is non-toxic and compatible with human tissue and bodily fluids.

These unique properties make Nitinol alloy bars ideal for a wide range of applications, from medical devices to industrial tools and consumer products. The composition and processing of Nitinol bars can be tailored to meet specific industry requirements.

Company Profile

Our company Principle is " Quality first, Customer first".

CHANGZHOU DLX ALLOY CO, LTD was established in 2002 and has got Iso9001 International Quality Management System Certificate and SGS Certificate. Our factory is professional in researching and producing special alloy material. From melting, drawing, heat treatment, finishing and testing .We offer nickel-based, copper-based, and iron-based alloys, including super alloy, welding materials, anti-corrosion alloy, precision alloy, FeCrAl alloy, NiCr alloy, CuNi alloy, thermocouple and etc, in the form of wire, strip, ribbon, bar, tube, plate.

If any requirements and questions, please feel free to reach:

Sophie Wang | Sales +86 13275217619

International Sales Depart.

Jiangsu Victory Technology Co., Ltd

A: NO.32 West Taihu Road, Xinbei District, Changzhou, Jiangsu

FAQ

Oct.1-7 and Chinese New Year holiday . Pls email us during our holiday if u have any question.

Do you provide free samples?

Yes,we can provide a free sample for testing,buyer should bear all the shipping costs.

What is your payment terms?

T/T,L/C,D/A,D/P,Western Union,MoneyGram,Paypal

What is the lead time?

Usually sample lead time is 7 days after payment has been confirmed.