Product Description

Nitinol Rods exhibit a remarkable combination of properties that make them well-suited for a variety of applications. These alloy rods are known for their robust construction, able to withstand demanding environments. Their durable nature ensures reliable performance, even under heavy use. Nitinol's versatility allows it to be tailored to specific needs, making the rods adaptable to diverse applications. The material's inherent flexibility provides design engineers with increased freedom, while the corrosion-resistant characteristics extend the lifespan of nitinol components. Overall, nitinol rods offer a unique blend of strength, resilience, and adaptability that is valued across numerous industries

Applications

- Medical Devices:

- Stents for cardiovascular procedures

- Guidewires for minimally invasive surgeries

- Orthodontic archwires

- Orthopedic implants and instruments

- Aerospace & Defense:

- Actuators and valves for aircraft and spacecraft

- Shape memory components for morphing structures

- Vibration damping and impact absorption

- Consumer Electronics:

- Eyeglass frames with shape memory

- Cellular phone antennas

- Fasteners and connectors

- Industrial Applications:

- Couplings and connectors for pipes and tubes

- Vibration damping and energy dissipation

- Actuators for valves and switches

- Energy & Utilities:

- Pipe couplings and fittings

- Seismic dampers for infrastructure

- Thermal actuators for valves and switches

The unique properties of Nitinol, such as superelasticity, shape memory, and corrosion resistance, make it a versatile material across a wide range of industries and applications.

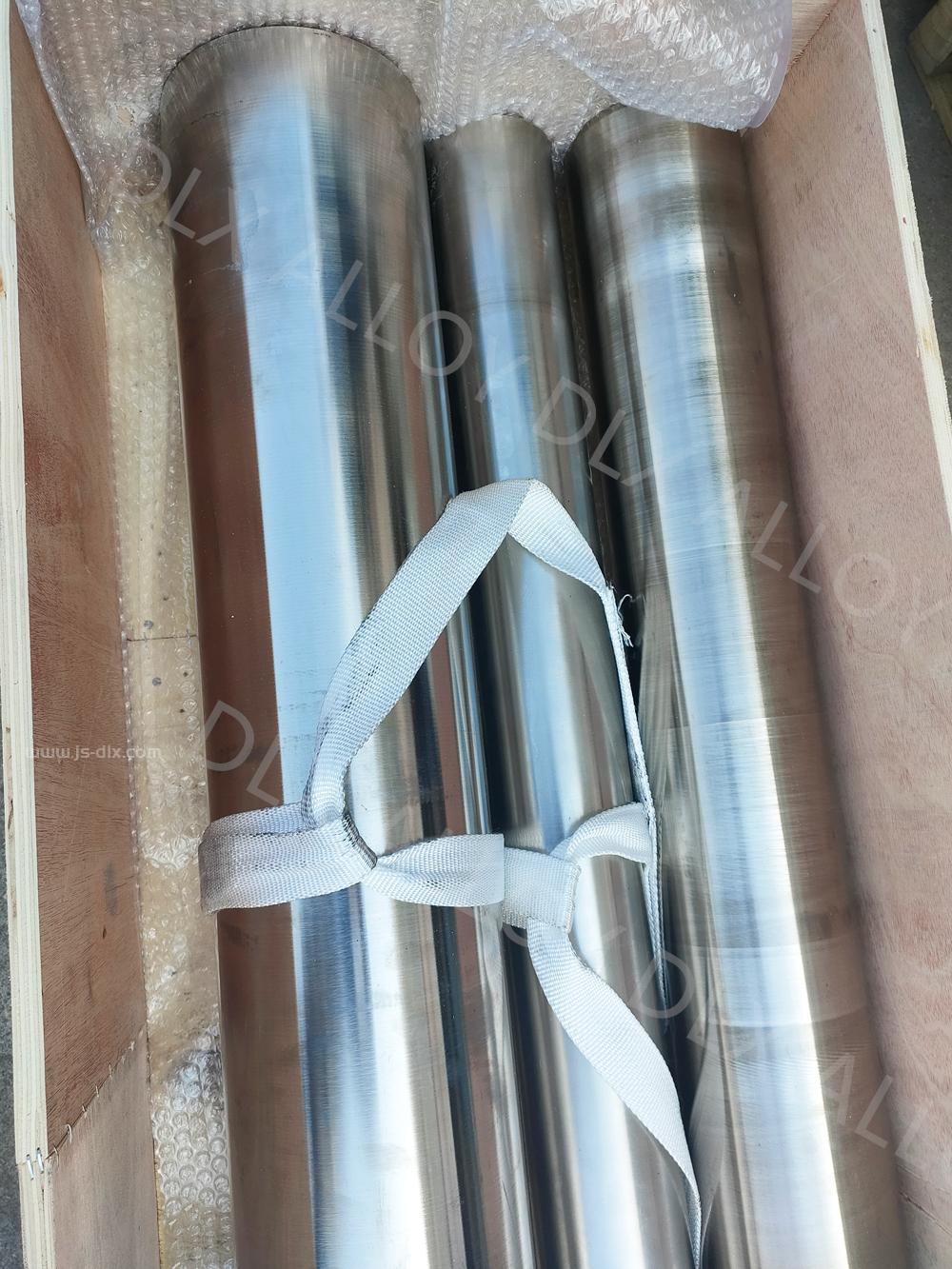

Detailed Photos

Smooth cutting

Export wooden box protection ensures that the goods arrive at the customer intact

Strictly produce according to the size required by the customer, and update the customer with accurate product parameters before delivery

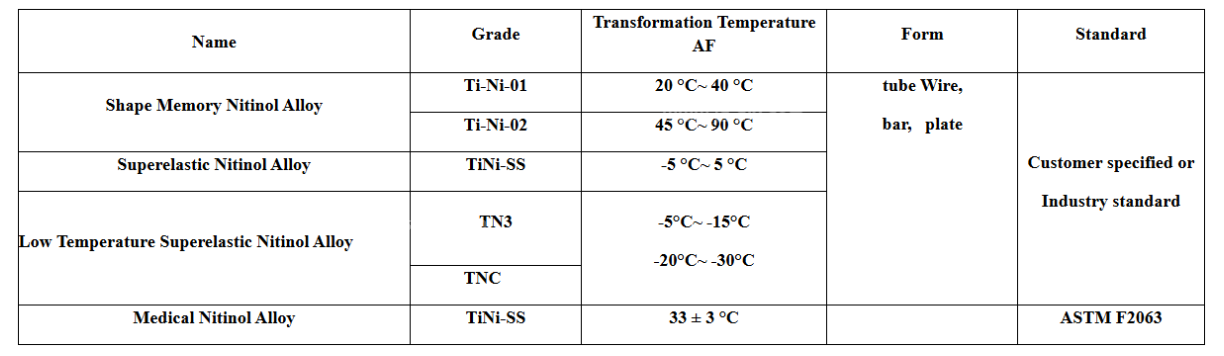

Product Parameters

- Nitinol (Nickel-Titanium) alloys typically contain 50-60% nickel and 40-50% titanium.

Specific Compositions:

- Equiatomic Nitinol: 50% nickel and 50% titanium, the most common and widely used composition.

- Nickel-Rich Nitinol: 51-55% nickel and 45-49% titanium, with higher transformation temperatures and stronger shape memory effects.

- Titanium-Rich Nitinol: 49-51% titanium and 49-51% nickel, with lower transformation temperatures and better corrosion resistance.

The exact composition of Nitinol rods can be customized and tailored to meet the specific requirements of different applications,

such as medical devices, aerospace, consumer products, and industrial uses.

The unique properties of Nitinol, including superelasticity, shape memory effect, and biocompatibility, are heavily dependent on the precise nickel and titanium content in the alloy composition.

Company Profile

Our company Principle is " Quality first, Customer first".

CHANGZHOU DLX ALLOY CO, LTD was established in 2002 and has got Iso9001 International Quality Management System Certificate and SGS Certificate. Our factory is professional in researching and producing special alloy material. From melting, drawing, heat treatment, finishing and testing .We offer nickel-based, copper-based, and iron-based alloys, including super alloy, welding materials, anti-corrosion alloy, precision alloy, FeCrAl alloy, NiCr alloy, CuNi alloy, thermocouple and etc, in the form of wire, strip, ribbon, bar, tube, plate.

If any requirements and questions, please feel free to reach:

Sophie Wang | Sales +86 13275217619

International Sales Depart.

Jiangsu Victory Technology Co., Ltd

A: NO.32 West Taihu Road, Xinbei District, Changzhou, Jiangsu

FAQ

Oct.1-7 and Chinese New Year holiday . Pls email us during our holiday if u have any question.

Do you provide free samples?

Yes,we can provide a free sample for testing,buyer should bear all the shipping costs.

What is your payment terms?

T/T,L/C,D/A,D/P,Western Union,MoneyGram,Paypal

What is the lead time?

Usually sample lead time is 7 days after payment has been confirmed.