Product Description

Nickel-Titanium (Nitinol) Rods: A Versatile Metallic Solution

Nitinol Rods, a remarkable product, offer unique properties sought across industries.

These elements, crafted with precision, harness the nitinol composition's inherent shape memory and superelasticity, unlocking innovative design possibilities.

Meticulously manufactured to exacting tolerances, nitinol rods can meet the precise needs of applications from medical to aerospace.

Beyond impressive mechanics, these rods exhibit excellent corrosion resistance and biocompatibility.Ensuring reliable, long-lasting performance in demanding environments.

Whether the application needs strength, flexibility, or thermal responsiveness, nitinol rods rise to the challenge.Enabling engineers and designers to push boundaries of traditional metallic materials.

Applications

Nickel-Titanium (Nitinol) Rods: Applications and Key Characteristics

Applications of Nitinol Rods:

1. Medical Devices: Nitinol rods are extensively used in medical applications due to their biocompatibility, shape memory, and superelasticity.

They are found in stents, guidewires, orthodontic archwires, and various implantable devices.

2. Aerospace Engineering: The lightweight, strong, and thermally responsive nature of nitinol rods make them valuable in aerospace components, such as actuators, fasteners, and structural elements.

3. Automotive Industry: Nitinol rods are used in automotive applications, including sensors, actuators, and shape-changing components for improved performance and fuel efficiency.

4. Consumer Goods: The unique properties of nitinol rods enable their use in consumer products, including eyeglass frames,

smart jewelry, and various household items that require flexibility, shape memory, or thermal responsiveness.

5. Industrial Applications: Nitinol rods find applications in industrial equipment, such as valves, couplings, and heat-activated mechanisms,

taking advantage of their exceptional mechanical and thermal characteristics.

Key Characteristics of Nitinol Rods:

1. Shape Memory Effect: Nitinol rods can remember and return to their original shape after deformation, making them ideal for applications requiring adaptability and self-correcting abilities.

2. Superelasticity: Nitinol rods can undergo large, reversible deformations without permanent damage, allowing for flexible and resilient behavior.

3. Corrosion Resistance: The nitinol composition provides excellent resistance to corrosion, enabling the rods to withstand harsh environments and maintain their integrity over extended use.

4. Biocompatibility: Nitinol is highly biocompatible, making it suitable for medical implants and devices that come into direct contact with the human body.

5. Thermal Responsiveness: Nitinol rods can be engineered to respond to changes in temperature, enabling the development of temperature-activated mechanisms and shape-shifting applications.

The versatility and unique properties of nitinol rods make them a valuable material across a wide range of industries, from cutting-edge medical technologies to innovative consumer products and beyond.

Detailed Photos

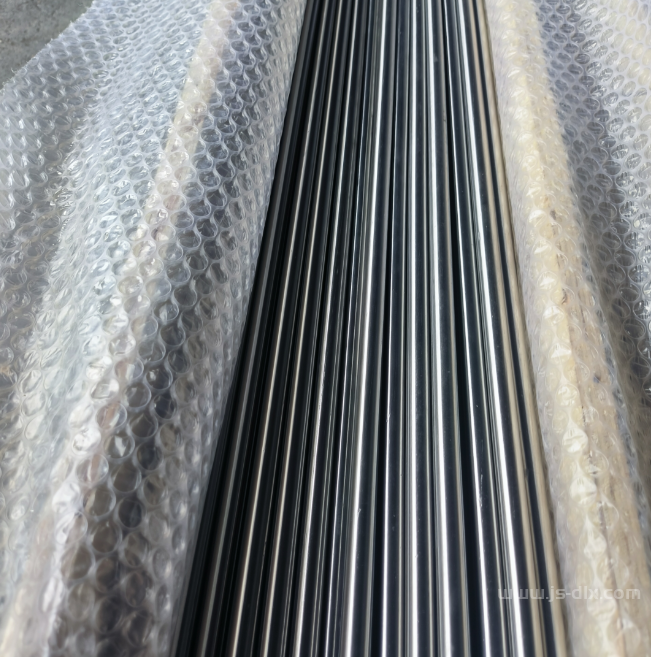

Exceptional Surface Finish:

- The nitinol rods in our inventory boast a gleaming, mirror-like surface finish.

- This polished exterior enhances the aesthetic appeal of the rods while also contributing to their exceptional corrosion resistance.

- The pristine appearance and structural integrity of the rods are preserved over time.

Precise Dimensional Tolerances:

- Our nitinol rods are crafted with uncompromising precision, manufactured to exacting dimensional tolerances.

- This allows for a perfect fit and seamless integration into a wide range of applications.

- Rigorous quality control measures ensure consistency and reliability in the size and shape of our products.

Secure Packaging for Safe Delivery:

- To ensure the safe and secure delivery of these delicate metallic components, we package the nitinol rods in sturdy wooden crates.

- This rugged packaging solution safeguards the rods from potential damage during transit.

- Our clients can have the peace of mind that their valuable shipment will arrive in pristine condition, ready for immediate use or further processing.

Versatile and Reliable Performance:

- Whether your application demands exceptional strength, flexibility, or thermal responsiveness, our precisely engineered nitinol rods are poised to exceed your expectations.

- Customers can experience the reliability and quality that our meticulously crafted nitinol offerings provide.

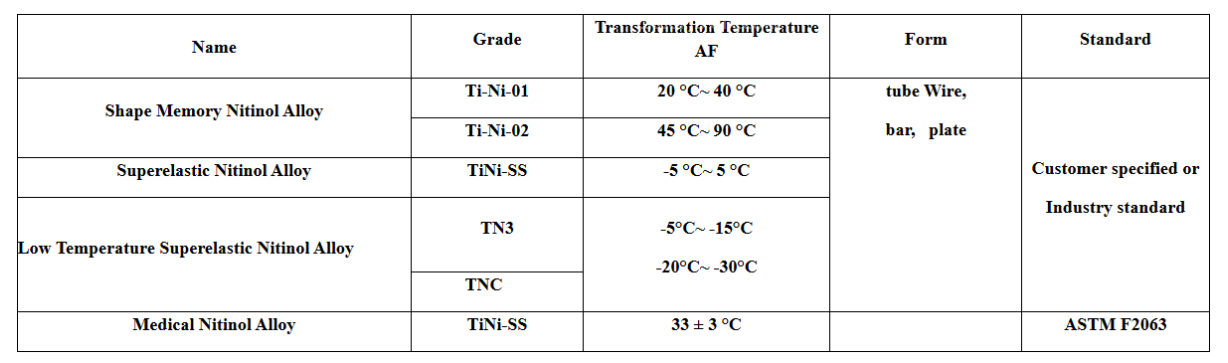

Product Parameters

The Nitinol Composition: The Optimal Nickel-Titanium Balance

Nitinol, the Unique Nickel-Titanium Alloy:

Nitinol rods are composed of a carefully crafted nickel-titanium alloy, which is the key to their exceptional properties and performance.

Nickel and Titanium: The Synergistic Duo:

- Nickel: The nickel content in the alloy provides the rods with their remarkable shape memory and superelastic characteristics.

- Titanium: The titanium component contributes to the rods' exceptional strength, lightweight, and corrosion resistance.

The Optimal Nickel-Titanium Ratio:

- The specific ratio of nickel to titanium in the nitinol composition is precisely controlled and optimized.

- This careful balance of the two elements is the driving force behind the rods' transformative performance.

Unleashing the Full Potential:

- The synergistic effect of nickel and titanium in the nitinol alloy unlocks the rods' full potential, enabling them to exhibit a unique combination of advanced properties.

- This precise composition is the foundation for the rods' exceptional shape memory, superelasticity, strength, and corrosion resistance.

Nickel's Contribution:

- The nickel content in the alloy is the key to the rods' shape memory effect, allowing them to remember and return to their original shape after deformation.

Titanium's Contribution:

- The titanium component endows the rods with their exceptional strength-to-weight ratio and superior corrosion resistance.

- Titanium also plays a crucial role in the rods' superelastic behavior, enabling them to undergo significant deformation and instantly recover their initial form.

Biocompatibility:

- The combination of nickel and titanium results in a biocompatible alloy, making nitinol rods suitable for medical and implant applications.

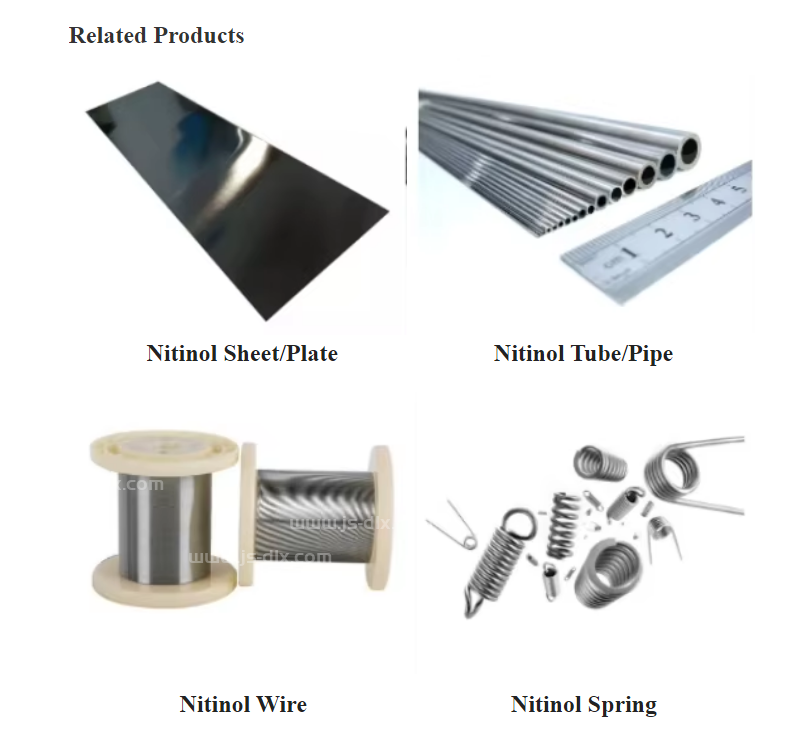

Recommended Products

Company Profile

Our company Principle is " Quality first, Customer first".

CHANGZHOU DLX ALLOY CO, LTD was established in 2002 and has got Iso9001 International Quality Management System Certificate and SGS Certificate. Our factory is professional in researching and producing special alloy material. From melting, drawing, heat treatment, finishing and testing .We offer nickel-based, copper-based, and iron-based alloys, including super alloy, welding materials, anti-corrosion alloy, precision alloy, FeCrAl alloy, NiCr alloy, CuNi alloy, thermocouple and etc, in the form of wire, strip, ribbon, bar, tube, plate.

If any requirements and questions, please feel free to reach:

Sophie Wang | Sales +86 13275217619

International Sales Depart.

Jiangsu Victory Technology Co., Ltd

A: NO.32 West Taihu Road, Xinbei District, Changzhou, Jiangsu

FAQ

Oct.1-7 and Chinese New Year holiday . Pls email us during our holiday if u have any question.

Do you provide free samples?

Yes,we can provide a free sample for testing,buyer should bear all the shipping costs.

What is your payment terms?

T/T,L/C,D/A,D/P,Western Union,MoneyGram,Paypal

What is the lead time?

Usually sample lead time is 7 days after payment has been confirmed.