Welcome to Changzhou DLX Alloy Co., Ltd.

Email:sales8@dlx-alloy.com Mobile/Whatsapp:+86 199 0611 9641

Specialized manufacturer of heaters, thermocouples and titanium,over 20 years.

Welcome to Changzhou DLX Alloy Co., Ltd.

Email:sales8@dlx-alloy.com Mobile/Whatsapp:+86 199 0611 9641

Specialized manufacturer of heaters, thermocouples and titanium,over 20 years.

Whatsapp:+86 199 0611 9641

Email:sales8@dlx-alloy.com

Add:NO.32 West Taihu Road, Xinbei District, Changzhou, Jiangsu,China

Nitinol Pipe

Product Details

Product Description

Nitinol is a smart material with unique properties, including shape memory and superelasticity. Its key characteristics are:

1. Shape memory effect: Nitinol can be deformed at low temperatures, but when heated, it can recover its original, pre-deformed shape.

This is due to the reversible phase transformation between the low-temperature martensite phase and the high-temperature austenite phase.

2. Superelasticity: Nitinol can undergo large amounts of elastic deformation, up to 8% strain, without permanent deformation.

This is caused by the stress-induced transformation from austenite to martensite, which occurs at a relatively constant stress level.

3. Biocompatibility: Nitinol is highly biocompatible, making it an ideal material for medical applications such as stents, orthodontic wires, and surgical instruments.

4. Corrosion resistance: Nitinol exhibits excellent corrosion resistance due to the formation of a passive titanium oxide layer on the surface.

Nitinol's unique properties have led to its widespread use in various applications, including biomedical devices, aerospace, and consumer products.

Applications

Premium Titanium Grade 2 Seamless Pipes (6mm-170mm OD) for Demanding Applications

- Durable and Corrosion-Resistant Titanium Construction

- Seamless Design for Enhanced Strength and Reliability

- Ideal for Automotive Exhaust Systems, Industrial Process Piping, and Chemical Equipment

Precision Nitinol Tube s (5.5mm-150mm OD) for Advanced Engineering

- Superelastic and Shape Memory Nitinol Alloy

- Versatile Applications in Medical Devices, Aerospace, and Industrial Automation

- Excellent Formability Allows Complex Shapes and Geometries

- Suitable for Welding, Cutting, Punching, and Other Fabrication Processes

Secure Wooden Packaging for Safe Transport and Storage

- Sturdy Wood Cases Protect Pipes and Tubes During Shipping

- Convenient for Handling and On-Site Storage

- Maintains Product Condition and Quality

Key features of the Nitinol tubes

Precision Nitinol Tubes (5.5mm-150mm OD) - Key Features:

Superelastic and Shape Memory Properties

- Able to withstand large deformations and return to original shape

- Provides flexibility and adaptability in engineering applications

Excellent Formability

- Can be easily bent, shaped, and formed into complex geometries

- Enables intricate designs and customized components

Corrosion and Fatigue Resistance

- Highly durable and able to withstand harsh environments

- Ideal for long-lasting performance in critical applications

Biocompatibility

- Safe for use in medical devices and implants

- Does not cause adverse reactions in the human body

Wide Temperature Operating Range

- Maintains performance across a broad temperature spectrum

- Suitable for diverse industrial and engineering needs

Detailed Photos

Rigorous Quality Assurance Prior to Shipment

Prior to shipment, we conduct meticulous dimensional inspections using precision calipers and comprehensive spectral analysis to thoroughly verify that the material composition and dimensions fully comply with the customer's exact requirements. Furthermore, the products are carefully packaged in sturdy wooden crates, which effectively safeguard the goods from any potential damage during transit, ensuring the safe and secure delivery of the materials to the customer's facilities.

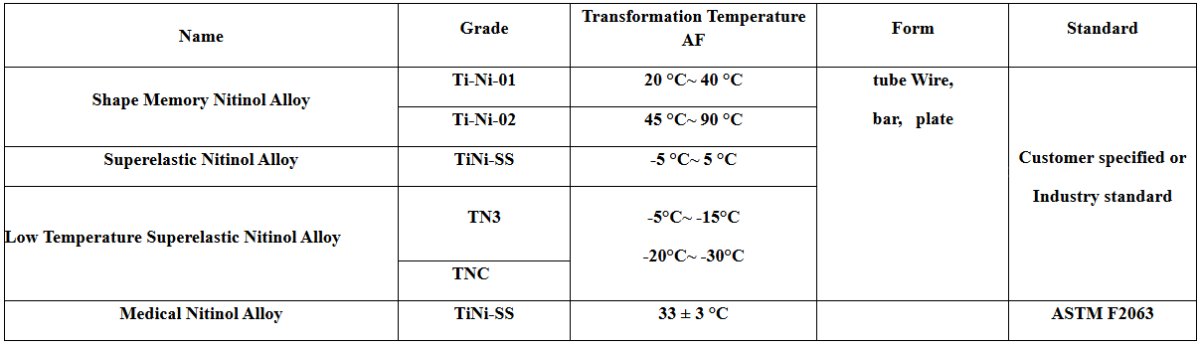

Product Parameters

The key components of the Nitinol alloy include:

Nickel (Ni):

- Provides the shape memory and superelastic characteristics

- Carefully balanced with Titanium for optimal material properties

Titanium (Ti):

- Contributes to the corrosion resistance and strength of the alloy

- Works in synergy with the Nickel for the desired performance

This specialized Nitinol alloy composition allows the tubes to be highly formable, fatigue-resistant, and versatile for a wide range of advanced engineering applications.

Recommended Products

Company Profile

Our company Principle is " Quality first, Customer first".

CHANGZHOU DLX ALLOY CO, LTD was established in 2002 and has got Iso9001 International Quality Management System Certificate and SGS Certificate. Our factory is professional in researching and producing special alloy material. From melting, drawing, heat treatment, finishing and testing .We offer nickel-based, copper-based, and iron-based alloys, including super alloy, welding materials, anti-corrosion alloy, precision alloy, FeCrAl alloy, NiCr alloy, CuNi alloy, thermocouple and etc, in the form of wire, strip, ribbon, bar, tube, plate.

If any requirements and questions, please feel free to reach:

Sophie Wang | Sales +86 13275217619

International Sales Depart.

Jiangsu Victory Technology Co., Ltd

A: NO.32 West Taihu Road, Xinbei District, Changzhou, Jiangsu

FAQ

What is your working time and contacting information?

Monday-Saturday : 7:30AM-17:00PM (Beijing time, GMT+08.00) We have public holiday during May.1-3,

Oct.1-7 and Chinese New Year holiday . Pls email us during our holiday if u have any question.

Do you provide free samples?

Yes,we can provide a free sample for testing,buyer should bear all the shipping costs.

What is your payment terms?

T/T,L/C,D/A,D/P,Western Union,MoneyGram,Paypal

What is the lead time?

Usually sample lead time is 7 days after payment has been confirmed.