Welcome to Changzhou DLX Alloy Co., Ltd.

Email:sales8@dlx-alloy.com Mobile/Whatsapp:+86 199 0611 9641

Specialized manufacturer of heaters, thermocouples and titanium,over 20 years.

Welcome to Changzhou DLX Alloy Co., Ltd.

Email:sales8@dlx-alloy.com Mobile/Whatsapp:+86 199 0611 9641

Specialized manufacturer of heaters, thermocouples and titanium,over 20 years.

Whatsapp:+86 199 0611 9641

Email:sales8@dlx-alloy.com

Add:NO.32 West Taihu Road, Xinbei District, Changzhou, Jiangsu,China

Nitinol Pipe

Product Details

Product Description

Here are the key points about Nitinol tubes in a bulleted format:

Nitinol Tubes: Extraordinary Flexibility and Shape Memory

Exceptional Material Properties:

- Superelasticity: Nitinol tubes can undergo extreme deformations and bending without permanent damage, reverting to their original shape.

- Shape Memory Effect: Nitinol tubes can be precision-formed into complex shapes and configurations, which they automatically recover when exposed to specific temperatures.

- Corrosion Resistance: A protective passive oxide layer makes Nitinol tubes highly resistant to corrosion, enabling reliable performance in harsh environments.

Versatile Applications Across Industries:

- Medical Devices: Leveraged for stents, catheters, orthopedic implants, and other minimally invasive equipment.

- Aerospace Systems: Utilized for adaptive, self-adjusting components in aircraft, spacecraft, and related applications.

- Industrial Automation: Employed in equipment, piping, and actuators requiring strength, durability, and formability.

- Specialized Manufacturing: Enabling complex fabrication techniques like bending, shaping, and joining.

- Chemical Processing: Corrosion-resistant Nitinol tubes excel in harsh chemical environments.

- Diverse Engineering Solutions: Wide-ranging applications benefiting from Nitinol's unique material properties.

Key Advantages of Nitinol Tubes:

- Unparalleled Flexibility and Conformity

- Adaptable Design with Shape Memory Capabilities

- Corrosion-Resistant Durability for Demanding Environments

- Versatility Across Multiple Industries and Applications

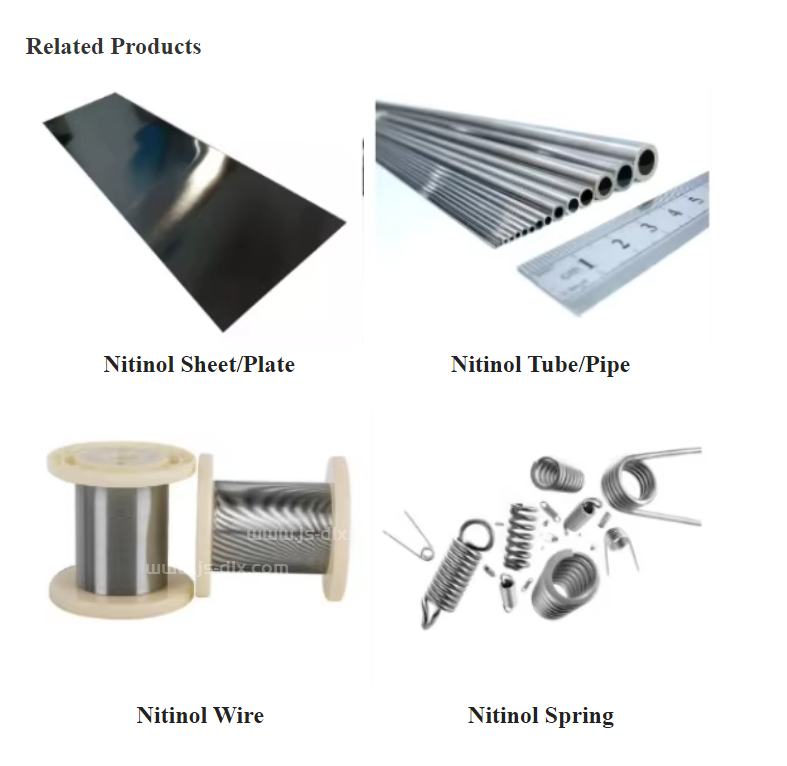

Detailed Photos

Tailored Nickel Titanium Alloy Plates to Your Exact Specifications

Secure Packaging for Safe Delivery

At our manufacturing facility, we have the capability to precisely customize the thickness of our Nickel Titanium alloy plates to match your unique requirements.

Prior to shipment, we will provide you with detailed photographic documentation showcasing the exact measurements of the plates.

This quality assurance step allows you to thoroughly review and confirm that the dimensions perfectly align with your specifications, guaranteeing that the final product meets your needs.

To ensure the Nickel Titanium alloy plates arrive at your facility in pristine condition, we take great care in the packaging process.

We utilize sturdy wooden pallets or crates to securely contain the product.

This robust packaging method effectively shields the plates from any potential damage that could occur during transit.

With our customization capabilities and secure packaging protocols, you can trust that your Nickel Titanium alloy plates will be tailored to your exact requirements and delivered safely to your door.

We are committed to providing you with a seamless procurement experience and a final product that exceeds your expectations.

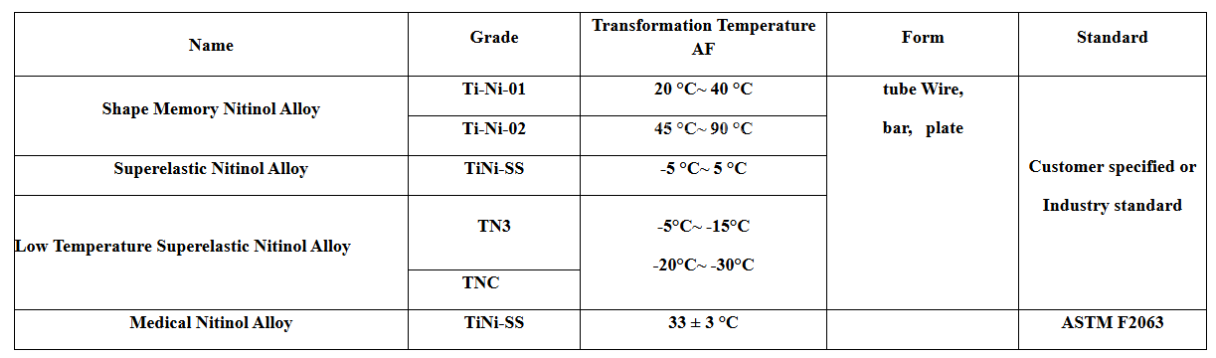

Product Parameters

Nitinol: A Nickel-Titanium Alloy

Nitinol is typically made up of:

- 50-55% Nickel (Ni)

- 45-50% Titanium (Ti)

This balanced nickel-titanium ratio is the foundation of Nitinol's unique properties, such as its shape memory and superelasticity.

Small amounts of other metals, like copper, iron, aluminum, or chromium, may also be added to the alloy to optimize its performance for specific applications.

Materials engineers can tailor the exact Nitinol composition to meet the requirements of different industries, from medical devices to aerospace. By adjusting the elemental blend, they can fine-tune Nitinol's distinctive characteristics.

This compositional flexibility is a key advantage of Nitinol, allowing it to be engineered into a wide range of high-performance solutions.

Company Profile

Our company Principle is " Quality first, Customer first".

CHANGZHOU DLX ALLOY CO, LTD was established in 2002 and has got Iso9001 International Quality Management System Certificate and SGS Certificate. Our factory is professional in researching and producing special alloy material. From melting, drawing, heat treatment, finishing and testing .We offer nickel-based, copper-based, and iron-based alloys, including super alloy, welding materials, anti-corrosion alloy, precision alloy, FeCrAl alloy, NiCr alloy, CuNi alloy, thermocouple and etc, in the form of wire, strip, ribbon, bar, tube, plate.

If any requirements and questions, please feel free to reach:

Sophie Wang | Sales +86 13275217619

International Sales Depart.

Jiangsu Victory Technology Co., Ltd

A: NO.32 West Taihu Road, Xinbei District, Changzhou, Jiangsu

What is your working time and contacting information?

Monday-Saturday : 7:30AM-17:00PM (Beijing time, GMT+08.00) We have public holiday during May.1-3,

Oct.1-7 and Chinese New Year holiday . Pls email us during our holiday if u have any question.

Do you provide free samples?

Yes,we can provide a free sample for testing,buyer should bear all the shipping costs.

What is your payment terms?

T/T,L/C,D/A,D/P,Western Union,MoneyGram,Paypal

What is the lead time?

Usually sample lead time is 7 days after payment has been confirmed.