Welcome to Changzhou DLX Alloy Co., Ltd.

Email:sales8@dlx-alloy.com Mobile/Whatsapp:+86 199 0611 9641

Specialized manufacturer of heaters, thermocouples and titanium,over 20 years.

Welcome to Changzhou DLX Alloy Co., Ltd.

Email:sales8@dlx-alloy.com Mobile/Whatsapp:+86 199 0611 9641

Specialized manufacturer of heaters, thermocouples and titanium,over 20 years.

Whatsapp:+86 199 0611 9641

Email:sales8@dlx-alloy.com

Add:NO.32 West Taihu Road, Xinbei District, Changzhou, Jiangsu,China

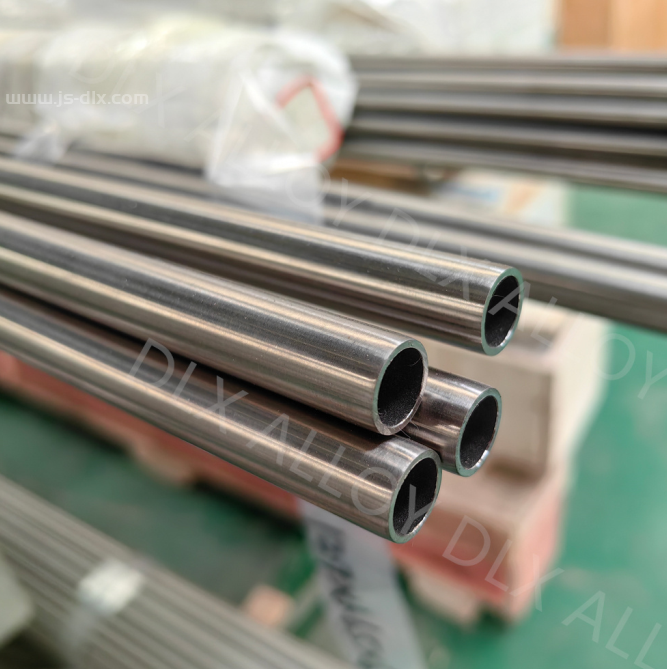

Nitinol Pipe

Product Details

Nitinol Tubing - Redefining Alloy Capabilities

- Nitinol tubing can recover its original shape after deformation

- Conventional metals lack this shape memory superpower

- Nitinol exhibits remarkable superelasticity - withstanding large elastic deformations without damage

- Far exceeds the elasticity of typical metal alloy tubing

- Nitinol tubing demonstrates outstanding corrosion resistance in harsh environments

- Outperforms stainless steel and other alloy tubes

- Nitinol's composition can be precisely customized for specific applications

- By adjusting nickel-titanium ratio and adding trace elements

- Provides unmatched flexibility versus conventional alloy tubing

These exceptional capabilities - shape memory, elasticity, corrosion resistance, and customizability - make Nitinol tubing a paradigm shift from conventional metal alloys.

Applications

Medical Marvels

- Nitinol tubing's shape memory and superelasticity make it a premier biomaterial

- Used extensively in medical devices like dental braces, stents, and catheters

Aerospace Advantage

- Lightweight and corrosion-resistant, Nitinol tubing excels in aerospace applications

- Vital components in aircraft landing gear and satellite antenna mechanisms

Industrial Automation Innovator

- Nitinol tubing's shape memory enables complex motion in precision components

- Ideal for fabricating advanced actuators, sensors, and valves

Consumer Trends

- Emerging use in smartphone casings, earphones, and other electronics

- Providing unique aesthetic and structural capabilities

With its exceptional mechanical properties, malleability, and corrosion resistance,

Nitinol tubing has become a versatile engineering material across diverse industries - revolutionizing medical devices, aerospace systems, industrial automation, and consumer electronics.

Detailed Photos

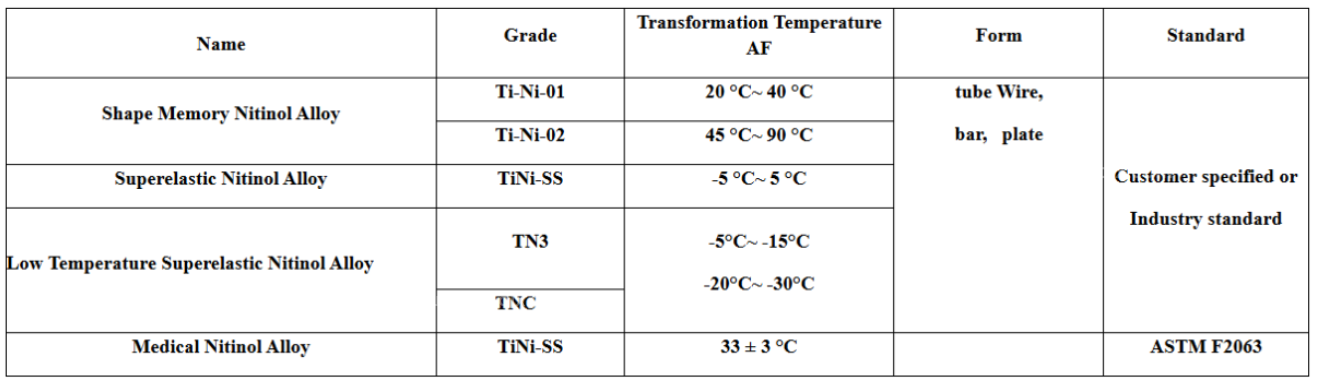

Product Parameters

Nitinol is an alloy composed primarily of nickel (Ni) and titanium (Ti). The typical composition of nitinol is around 50-60% nickel and 40-50% titanium.

The exact composition of nitinol can vary depending on the specific application and the desired properties. Some common nitinol compositions include:

1. Equiatomic nitinol: This composition has an equal atomic percentage of nickel and titanium, usually around 50% Ni and 50% Ti.

This is the most common and well-studied composition of nitinol.

2. Nickel-rich nitinol: This composition has a slightly higher percentage of nickel, typically around 51-55% Ni and 45-49% Ti.

Nickel-rich nitinol exhibits a higher transformation temperature and a stronger shape memory effect.

3. Titanium-rich nitinol: This composition has a slightly higher percentage of titanium, typically around 49-51% Ti and 49-51% Ni.

Titanium-rich nitinol has a lower transformation temperature and a higher corrosion resistance compared to nickel-rich nitinol.

The precise composition of nitinol can be tailored to meet the specific requirements of different applications.

The ratio of nickel to titanium, as well as the presence of additional alloying elements,

can be adjusted to fine-tune the material's properties, such as the transformation temperature, strength, and corrosion resistance.

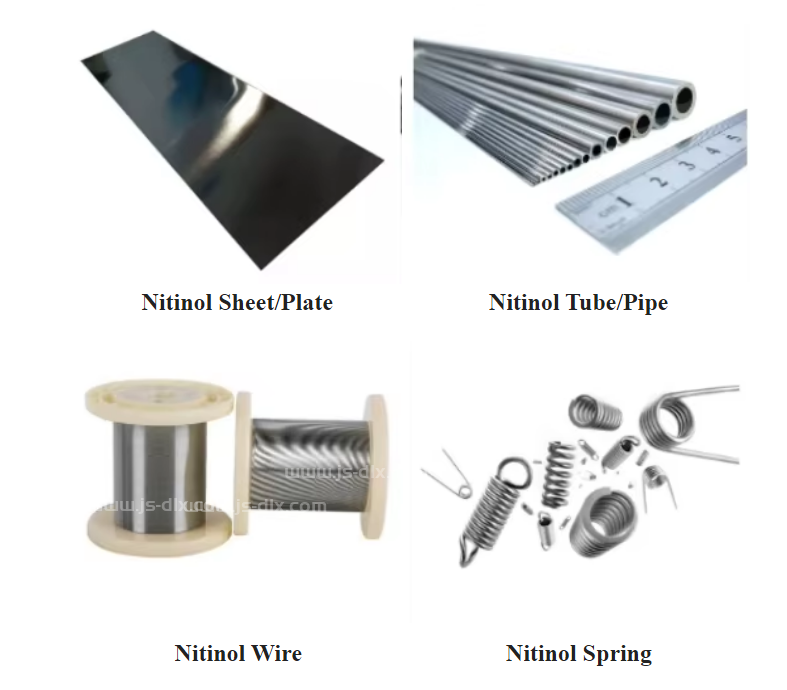

Recommended Products

Company Profile

Our company Principle is " Quality first, Customer first".

CHANGZHOU DLX ALLOY CO, LTD was established in 2002 and has got Iso9001 International Quality Management System Certificate and SGS Certificate.

Our factory is professional in researching and producing special alloy material. From melting, drawing, heat treatment, finishing and testing .

We offer nickel-based, copper-based, and iron-based alloys, including super alloy, welding materials, anti-corrosion alloy, precision alloy,

FeCrAl alloy, NiCr alloy, CuNi alloy, thermocouple and etc, in the form of wire, strip, ribbon, bar, tube, plate.

If any requirements and questions, please feel free to reach:

Sophie Wang | Sales +86 13275217619

International Sales Depart.

Jiangsu Victory Technology Co., Ltd

A: NO.32 West Taihu Road, Xinbei District, Changzhou, Jiangsu

What is your working time and contacting information?

Monday-Saturday : 7:30AM-17:00PM (Beijing time, GMT+08.00) We have public holiday during May.1-3,

Oct.1-7 and Chinese New Year holiday . Pls email us during our holiday if u have any question.

Do you provide free samples?

Yes,we can provide a free sample for testing,buyer should bear all the shipping costs.

What is your payment terms?

T/T,L/C,D/A,D/P,Western Union,MoneyGram,Paypal

What is the lead time?

Usually sample lead time is 7 days after payment has been confirmed

Previous article:High-Performance Responsive Nitinol Tubes Designed For Aerospace Engineering

Next article:High-Strength Nitinol Tube for Medical Implants