Welcome to Changzhou DLX Alloy Co., Ltd.

Email:sales8@dlx-alloy.com Mobile/Whatsapp:+86 199 0611 9641

Specialized manufacturer of heaters, thermocouples and titanium,over 20 years.

Welcome to Changzhou DLX Alloy Co., Ltd.

Email:sales8@dlx-alloy.com Mobile/Whatsapp:+86 199 0611 9641

Specialized manufacturer of heaters, thermocouples and titanium,over 20 years.

Whatsapp:+86 199 0611 9641

Email:sales8@dlx-alloy.com

Add:NO.32 West Taihu Road, Xinbei District, Changzhou, Jiangsu,China

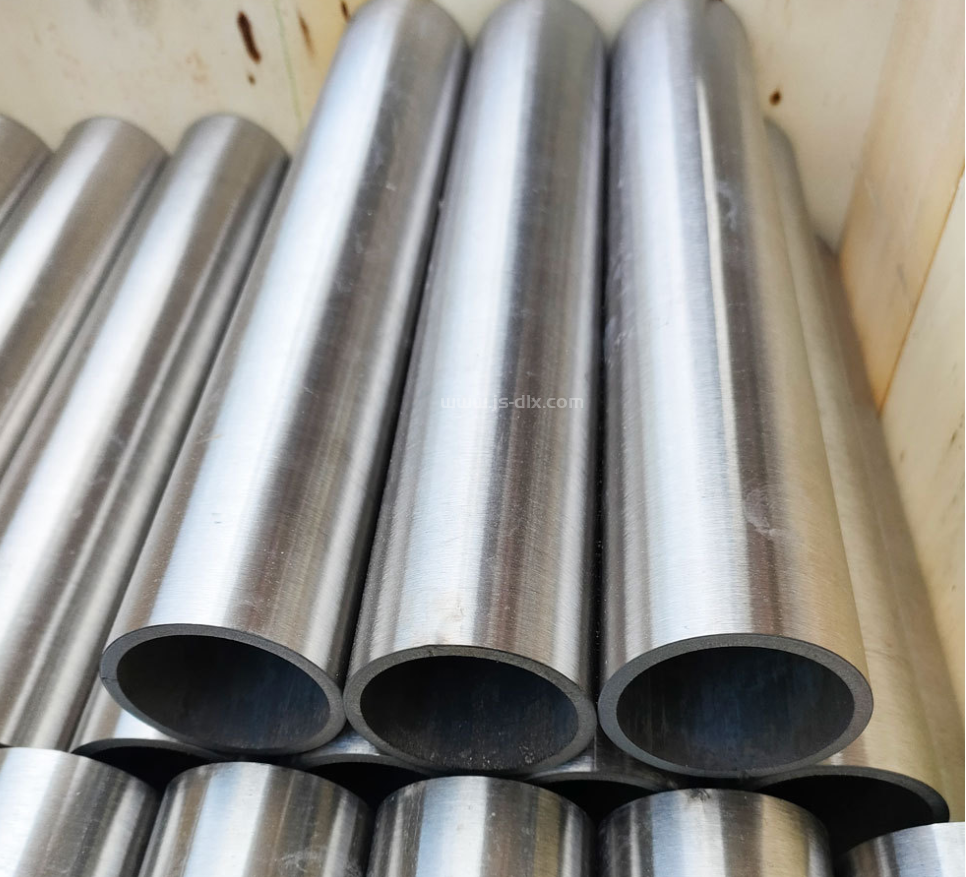

Nitinol Pipe

Product Details

Product Description

Nitinol tubing is widely acclaimed for its exceptional material properties that make it a versatile engineering solution. Its main advantages include:

Superelasticity - Nitinol tubing can withstand extreme deformation without damage, and readily recover its original shape.

This remarkable elasticity makes it highly suitable for applications requiring flexible, compliant materials.

Shape Memory Effect - Nitinol tubing can be precisely formed into complex shapes and configurations, and will automatically revert to its original shape when heated.

This unique memory function opens up vast design possibilities for engineers.

Excellent Corrosion Resistance - Nitinol forms a protective oxide layer on its surface, enabling it to maintain reliable performance even in harsh environments.

These outstanding material characteristics have made Nitinol tubing a preferred choice across diverse industries, from medical devices to aerospace.

Leveraging its exceptional flexibility, shape memory, and corrosion resistance, Nitinol can provide innovative solutions for a wide range of specialized applications.

Key application areas of Nitinol tubing

1. Medical Devices:

- Nitinol tubing is widely used in medical devices such as dental braces, stents, and catheters.

- Its shape memory and superelastic properties make it an ideal biomaterial.

2. Aerospace:

- Nitinol tubing has extensive applications in the aerospace industry, such as in the actuators and drive mechanisms of aircraft landing gear and satellite antennas.

- Its lightweight and corrosion resistance properties are well-suited for aerospace applications.

3. Industrial Automation:

- In the industrial automation field, Nitinol tubing can be used to fabricate precision mechanical components like actuators, sensors, and valves.

- Its shape memory capability enables it to execute complex motion sequences.

4. Consumer Electronics:

- The use of Nitinol tubing is also growing in consumer electronics products like smartphone casings and earphones.

- It can provide unique aesthetic and structural characteristics for these products.

In summary, Nitinol tubing, with its exceptional mechanical properties, high malleability, and outstanding corrosion resistance,

has found broad applications in the medical, aerospace, industrial automation, and consumer electronics sectors, making it a highly functional and versatile engineering material.

Detailed Photos

Smooth cut

Bright surface

Complete packaging to prevent any damage during transportation

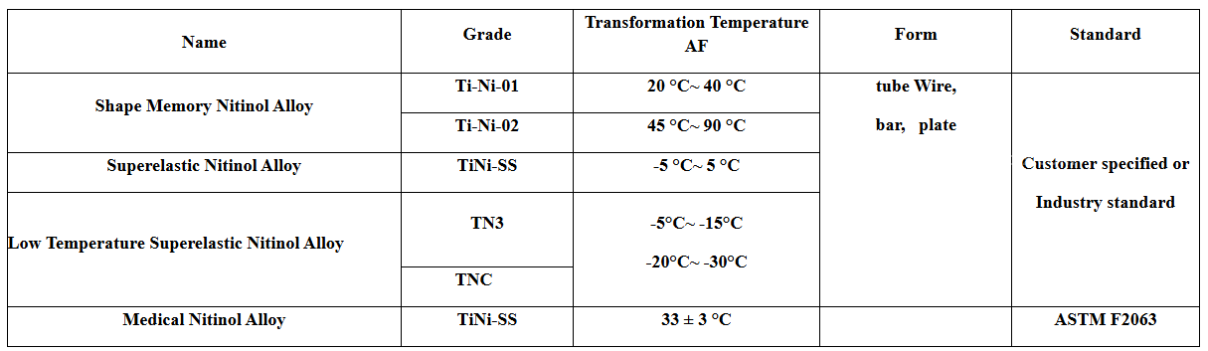

Product Parameters

Nitinol, the renowned shape memory alloy, is primarily composed of:

- Nickel (Ni): 50-55%

- Titanium (Ti): 45-50%

This near-equal ratio of nickel to titanium is the foundation of Nitinol's exceptional shape memory and superelastic properties.

Beyond this base composition, small amounts of other elements like copper, iron, aluminum, or chromium can be added to fine-tune Nitinol's characteristics for specific applications.

This flexibility to precisely engineer the Nitinol composition is a key advantage, allowing it to be optimized for diverse industries, from medical devices to aerospace.

By adjusting the elemental makeup, engineers can create customized Nitinol formulations to deliver the exact performance required for high-performance products and systems.

Recommended Products

Company Profile

Our company Principle is " Quality first, Customer first".

CHANGZHOU DLX ALLOY CO, LTD was established in 2002 and has got Iso9001 International Quality Management System Certificate and SGS Certificate. Our factory is professional in researching and producing special alloy material. From melting, drawing, heat treatment, finishing and testing .We offer nickel-based, copper-based, and iron-based alloys, including super alloy, welding materials, anti-corrosion alloy, precision alloy, FeCrAl alloy, NiCr alloy, CuNi alloy, thermocouple and etc, in the form of wire, strip, ribbon, bar, tube, plate.

If any requirements and questions, please feel free to reach:

Sophie Wang | Sales +86 13275217619

International Sales Depart.

Jiangsu Victory Technology Co., Ltd

A: NO.32 West Taihu Road, Xinbei District, Changzhou, Jiangsu

What is your working time and contacting information?

Monday-Saturday : 7:30AM-17:00PM (Beijing time, GMT+08.00) We have public holiday during May.1-3,

Oct.1-7 and Chinese New Year holiday . Pls email us during our holiday if u have any question.

Do you provide free samples?

Yes,we can provide a free sample for testing,buyer should bear all the shipping costs.

What is your payment terms?

T/T,L/C,D/A,D/P,Western Union,MoneyGram,Paypal

What is the lead time?

Usually sample lead time is 7 days after payment has been confirmed