Welcome to Changzhou DLX Alloy Co., Ltd.

Over 22 years of R&D and manufacturing experience

Product quality is guaranteed After-sales 7×24 hours service

Welcome to Changzhou DLX Alloy Co., Ltd.

Over 22 years of R&D and manufacturing experience

Product quality is guaranteed After-sales 7×24 hours service

Whatsapp:+86 199 0611 9641

Email:sales8@dlx-alloy.com

Add:NO.32 West Taihu Road, Xinbei District, Changzhou, Jiangsu,China

Nitinol Pipe

Product Details

Product Description

NiTi tubes are being utilized in energy applications, particularly in geothermal and oil extraction technologies. Their ability to withstand extreme temperatures and pressures makes them ideal for the harsh conditions encountered in these environments. The durability of nickel-titanium tubes contributes to the efficiency and safety of energy production processes, making them a valuable asset in the quest for sustainable energy solutions.

Applications

Advantages:

Thermal Shape Recovery: NiTi tubes can return to their original form when heated or cooled, providing utility in various engineering applications.

Superelastic Properties: Capable of significant deformation without permanent damage, these tubes exhibit remarkable flexibility.

Corrosion-Resistant: Their strong resistance to corrosion makes them suitable for use in harsh environments, promoting longevity.

Biocompatible Nature: Ideal for medical applications, NiTi tubes are safe for implantation and interaction with biological systems.

Reduced Weight: With a superior strength-to-weight ratio, these tubes help minimize the overall weight of structures.

Applications:

Medical Equipment: Frequently utilized in vascular stents, guidewires, and dental tools to enhance surgical procedures.

Aerospace Engineering: Critical for lightweight components in aircraft, contributing to improved performance and fuel efficiency.

Automotive Components: Employed in suspension systems and other critical parts that require resilience under stress.

Energy Sector: Effective in oil and gas extraction as well as geothermal energy systems, enduring extreme conditions.

Robotic Systems: Integrated into flexible joints and actuators, allowing robots to mimic human movements more naturally.

Detailed Photos

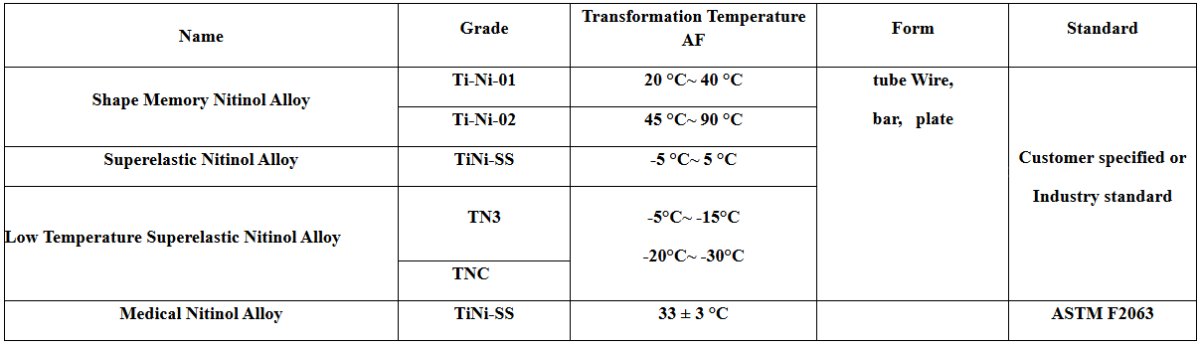

Product Parameters

Recommended products

Company Profile

Our company Principle is " Quality first, Customer first".

CHANGZHOU DLX ALLOY CO, LTD was established in 2002 and has got Iso9001 International Quality Management System Certificate and SGS Certificate. Our factory is professional in researching and producing special alloy material. From melting, drawing, heat treatment, finishing and testing .We offer nickel-based, copper-based, and iron-based alloys, including super alloy, welding materials, anti-corrosion alloy, precision alloy, FeCrAl alloy, NiCr alloy, CuNi alloy, thermocouple and etc, in the form of wire, strip, ribbon, bar, tube, plate.

If any requirements and questions, please feel free to reach:

Sophie Wang | Sales +86 13275217619

International Sales Depart.

Jiangsu Victory Technology Co., Ltd

A: NO.32 West Taihu Road, Xinbei District, Changzhou, Jiangsu

FAQ

Previous article:Multifunctional Nitinol Tube for Robotics

Next article:Oxidation-Resistant Nitinol Tube for Chemical Industry