Product Description

NiTi tubes are celebrated for their exceptional mechanical properties, which include high strength-to-weight ratios and excellent fatigue resistance. These attributes enable their use in demanding environments, such as aerospace engineering, where lightweight materials are essential for enhancing fuel efficiency and overall aircraft performance. The adaptability of NiTi tubes allows engineers to design components that meet stringent safety and performance standards.

Applications

Advantages:

Shape Memory Properties: NiTi tubes can revert to their original shape after deformation when subjected to temperature changes, making them versatile for various applications.

Exceptional Elasticity: These tubes demonstrate superelasticity, allowing them to endure substantial deformation without permanent damage, which is crucial in dynamic environments.

Durability: Their corrosion-resistant nature makes them suitable for use in aggressive environments, thereby enhancing their longevity.

Biocompatibility: Friendly to biological systems, they are extensively used in medical implants and devices, ensuring patient safety.

Reduced Weight: NiTi tubes are lighter than traditional materials, contributing to overall weight savings in various structures.

Applications:

Healthcare: Widely used in devices such as stents and orthodontic wires, aiding in complex medical procedures.

Aerospace Engineering: Critical for lightweight components in aircraft, helping to improve fuel efficiency and performance.

Automotive Applications: Found in suspension systems and high-temperature exhaust systems, where durability is essential.

Energy Production: Suitable for applications in oil and gas extraction, as well as geothermal energy systems.

Robotics and Actuation: Used in advanced robotics, providing flexibility and precision in movement.

Detailed Photos

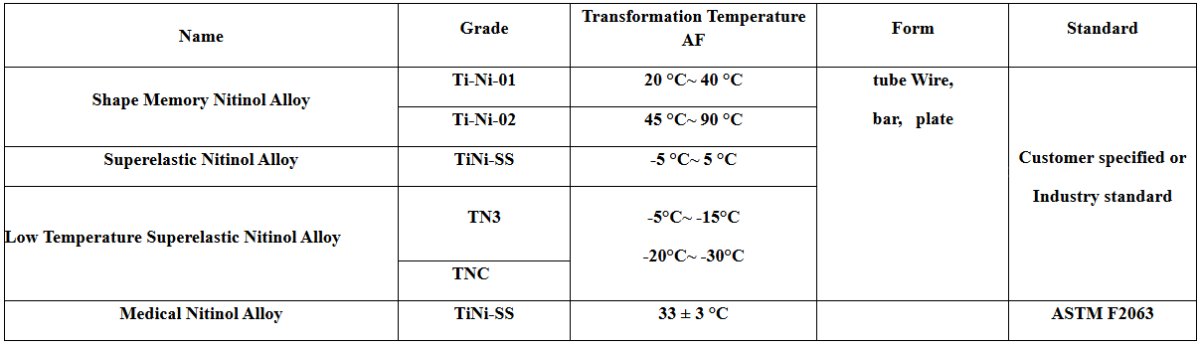

Product Parameters

Recommended products

Company Profile

Our company Principle is " Quality first, Customer first".

CHANGZHOU DLX ALLOY CO, LTD was established in 2002 and has got Iso9001 International Quality Management System Certificate and SGS Certificate. Our factory is professional in researching and producing special alloy material. From melting, drawing, heat treatment, finishing and testing .We offer nickel-based, copper-based, and iron-based alloys, including super alloy, welding materials, anti-corrosion alloy, precision alloy, FeCrAl alloy, NiCr alloy, CuNi alloy, thermocouple and etc, in the form of wire, strip, ribbon, bar, tube, plate.

If any requirements and questions, please feel free to reach:

Sophie Wang | Sales +86 13275217619

International Sales Depart.

Jiangsu Victory Technology Co., Ltd

A: NO.32 West Taihu Road, Xinbei District, Changzhou, Jiangsu

FAQ

Oct.1-7 and Chinese New Year holiday . Pls email us during our holiday if u have any question.

Do you provide free samples?

Yes,we can provide a free sample for testing,buyer should bear all the shipping costs.

What is your payment terms?

T/T,L/C,D/A,D/P,Western Union,MoneyGram,Paypal

What is the lead time?

Usually sample lead time is 7 days after payment has been confirmed.