Product Description

Nitinol tubing is a versatile material that can be employed in its natural, unaltered state or precisely laser-cut into individual components, such as stents, frames, or other specialized parts. Its exceptional superelasticity, combined with its shape memory ability, makes Nitinol a highly desirable material for the creation of sophisticated medical devices. The superelastic properties of Nitinol enable it to endure substantial mechanical stresses without permanent deformation, while its shape memory effect allows the material to return to its pre-set shape when exposed to specific temperatures. These unique characteristics are particularly beneficial in the design of medical devices that require a combination of flexibility, durability, and reliability. Nitinol's ability to adapt to a wide variety of shapes and environmental conditions ensures optimal functionality in complex applications where precision and performance are critical. This adaptability, along with its resistance to fatigue and biocompatibility, makes Nitinol an ideal material for use in life-saving medical devices, such as vascular stents, guidewires, and various types of implants, where both mechanical reliability and patient safety are of utmost importance.

Applications:

Medical Devices: Widely used in stents, catheters, and guidewires due to their exceptional flexibility and shape memory properties.

Robotics: Employed in actuators and robotic systems where lightweight and adaptable materials are essential.

Aerospace: Utilized in applications requiring lightweight tubing that can endure extreme conditions and revert to a specific shape.

Consumer Products: Incorporated into various items, such as eyeglass frames and flexible tubing for specialized uses.

Advantages:

Shape Memory Effect: Nitinol tubes can return to a predetermined shape upon heating, making them ideal for applications that require adaptability.

Superelasticity: Capable of undergoing significant deformation and returning to their original shape upon unloading, providing remarkable flexibility and resilience.

Biocompatibility: Safe for medical applications, minimizing the risk of adverse reactions within the human body.

Corrosion Resistance: Exceptional resistance to corrosion enhances durability across various environments, particularly in medical and harsh industrial settings.

Characteristics of Nitinol Tubes:

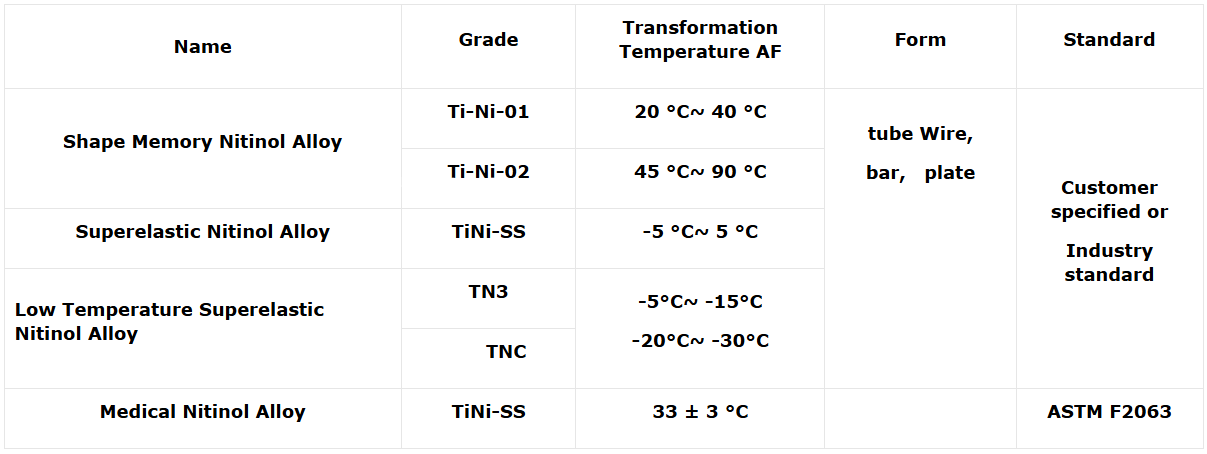

Composition: Primarily composed of nickel and titanium, typically in a near-equiatomic ratio.

Temperature Sensitivity: The transformation temperature can be customized during manufacturing to meet specific application requirements.

Mechanical Properties: Exhibits unique features such as high elasticity, fatigue resistance, and the ability to recover from significant deformations.

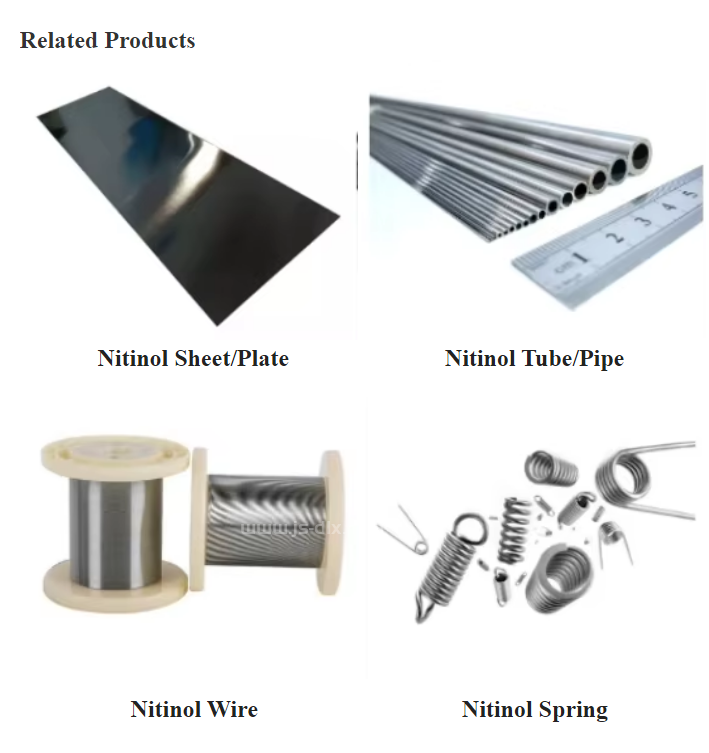

Formability: Can be manufactured into thin-walled tubes while maintaining both strength and flexibility.

Our Advantages

FAQ

1. How can I contact with your company?

We are always ready to serve you via Email, Telephone, Fax, Skype, Whatsapp, Wechat or Mobile

telephone.

2. What is your working time?

Monday-Saturday : 7:30AM-17:00PM (Beijing time, GMT+08.00)

We have public holiday during May.1-3, Oct.1-7 and Chinese New Year holiday . Pls email us during our holiday if u have any question.

3. Do you provide free samples?

Yes, we can provide a free sample for testing, buyer should bear all the shipping costs.

4. What is your payment terms?

T/T,L/C,D/A,D/P,Western Union,MoneyGram,Paypal

5. What is the lead time?

Usually sample lead time is 7 days after payment has been confirmed.