Product Description

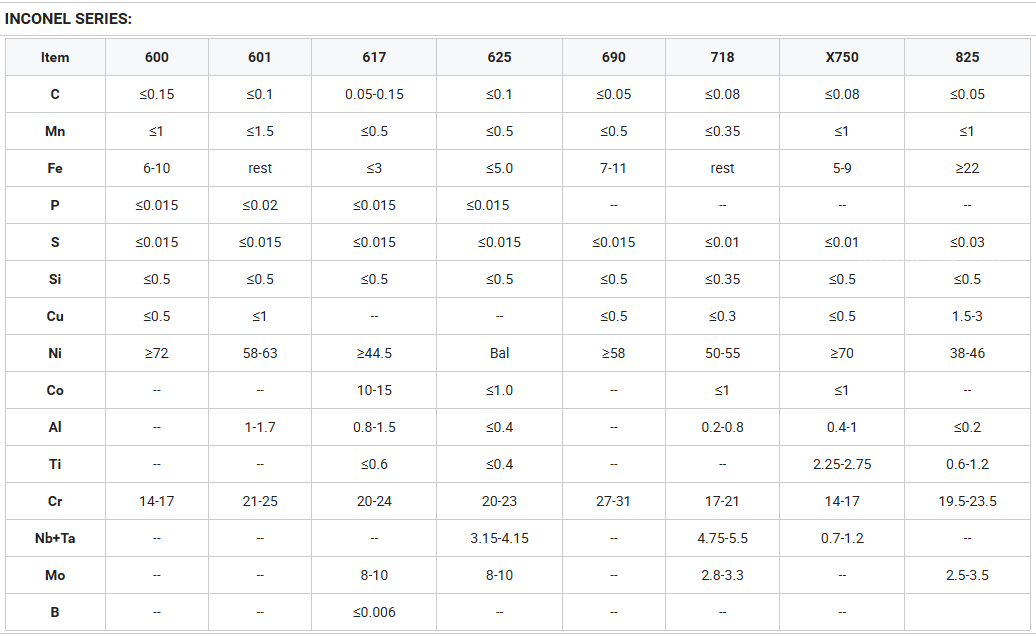

| Model No. | Inconel X750 |

| Type | Nickel Wire |

| Density | 8.47 |

| Elongation | 2~5 |

| Technology | Cold Drawing |

| Melting Range | 1354-1413c |

| Tensile Strength | 1170-1520MPa |

| Yield Strength | 1035-1450MPa |

| Surface | Bright/Acid White/Oxidation |

| Transport Package | Carton or Wooden Box |

High-Temperature Resistant Inconel X750 Wire For Industrial Applications

Inconel X-750 (UNS N07750/W. Nr. 2.4669) is a precipitation-hardenable nickel-chromium alloy renowned for its robust corrosion and oxidation resistance, as well as its high strength at temperatures up to 1300°F. While precipitation hardening effects diminish at temperatures above 1300°F, heat-treated X-750 retains significant strength up to 1800°F. Additionally, Alloy X-750 exhibits excellent performance even at cryogenic temperatures.

Inconel X750 Wire: Exceptional Strength and Resistance for High-Temperature Environments

Inconel X750 is a high-performance nickel-chromium alloy designed for applications requiring superior strength, oxidation, and corrosion resistance. Known for its exceptional mechanical properties and durability, Inconel X750 is ideal for extreme temperature environments, ranging from cryogenic to elevated temperatures.

Key Features:

High-Temperature Strength: Inconel X750 maintains impressive strength and stability up to 1300°F (700°C), with heat-treated variants sustaining useful strength up to 1800°F (980°C).

Corrosion and Oxidation Resistance: The alloy provides robust protection against oxidation and corrosion, making it suitable for harsh environments.

Cryogenic Performance: Inconel X750 retains excellent mechanical properties even at cryogenic temperatures, ensuring reliability in a wide range of conditions.

Precipitation Hardening: Although the benefits of precipitation hardening decrease at temperatures above 1300°F, the alloy's heat-treated state remains highly effective for demanding applications.

Applications

Inconel X750 wire is extensively used in various industries, including:

Aerospace: For components such as turbine blades, seals, and springs that require high strength and thermal resistance.

Power Generation: In gas turbines, reactors, and other high-temperature components.

Chemical Processing: For equipment exposed to corrosive environments and elevated temperatures.

Marine Engineering: In parts exposed to harsh marine conditions, benefiting from its resistance to corrosion and oxidation.

Advantages:

Exceptional Durability: Provides reliable performance in extreme temperatures and corrosive environments.

Versatile Use: Suitable for a variety of applications due to its strength and resistance properties.

Long-Term Reliability: Reduces maintenance and replacement costs by maintaining performance over time.

Detailed Photos

Packaging&Shipping

Company Profile

About CHANGZHOU DLX ALLOY CO., LTD

Founded in 2002, CHANGZHOU DLX ALLOY CO., LTD is a leading manufacturer specializing in the research and production of specialized alloy materials. Our factory has earned both the ISO9001 International Quality Management System Certificate and SGS Certification, affirming our commitment to high standards of quality.

We are experts in the entire alloy production process, including melting, drawing, heat treatment, finishing, and rigorous testing. Our product range includes nickel-based, copper-based, and iron-based alloys, such as super alloys, welding materials, anti-corrosion alloys, precision alloys, FeCrAl alloys, NiCr alloys, CuNi alloys, and thermocouples. These are available in various forms including wire, strip, ribbon, bar, tube, and plate.

FAQ

What is Inconel X750 wire?

Inconel X750 wire is a high-performance nickel-chromium alloy known for its outstanding mechanical strength, oxidation resistance, and ability to withstand extreme temperatures. It is particularly valued in applications requiring durability and stability under high-stress conditions.

2. What are the main characteristics of Inconel X750 wire?Key features of Inconel X750 wire include:

High Temperature Tolerance: Maintains strength and stability up to 1300°F (700°C), with heat-treated forms capable of enduring temperatures up to 1800°F (980°C).

Corrosion Resistance: Offers robust protection against oxidation and corrosion, ideal for harsh environments.

Cryogenic Performance: Performs reliably at cryogenic temperatures, making it versatile for various applications.

Precipitation Hardening: Provides excellent mechanical properties due to precipitation hardening, although effectiveness decreases at higher temperatures.

3. What are common uses for Inconel X750 wire?Inconel X750 wire is utilized in several critical applications, including:

Aerospace: For components like turbine blades, seals, and springs that need high strength and thermal stability.

Power Generation: In high-temperature environments such as gas turbines and reactor components.

Chemical Processing: For equipment exposed to corrosive substances and extreme temperatures.

Marine Applications: In environments where resistance to saltwater corrosion is essential.