Product Description

Inconel Wire stands out for its exceptional mechanical properties and resistance to oxidation and carburization.

These characteristics make it an ideal choice for applications requiring durability under high temperatures, such as manufacturing components for industrial furnaces, gas turbines, and heat exchangers.

Its ability to maintain performance in fluctuating thermal conditions enhances its appeal across various sectors

Applications

1. Aerospace Technologies

Essential for Flight: Inconel wire is a key material in aerospace technologies, particularly in the creation of turbine blades and engine components that must endure extreme temperatures and pressure variations, ensuring safe and efficient operation.

2. Oil and Gas Exploration

Robust Solutions: Within the oil and gas exploration sector, Inconel wire is critical for downhole applications and pipeline systems, providing exceptional corrosion resistance and strength to handle high-pressure environments.

3. Nuclear Reactor Components

High-Performance Alloys: Inconel wire is integral to the construction of nuclear reactor components, such as fuel assemblies, where its ability to withstand radiation and high heat ensures the safety and efficiency of nuclear energy production.

4. Chemical Production Facilities

Durability in Harsh Conditions: In the chemical production realm, Inconel wire is favored for its resilience against corrosive substances and high temperatures, making it ideal for use in reactors and heat exchangers that demand reliable performance.

5. Marine Engineering Applications

Long-Lasting Performance: Inconel wire is extensively used in marine engineering for manufacturing key components, such as valves and propeller shafts, offering durability against the corrosive impact of seawater, thereby extending service life.

6. Industrial Heating Applications

Thermal Stability: Inconel wire is commonly utilized in industrial heating applications, particularly in heat treatment furnaces, where it functions effectively as a heating element, maintaining integrity under extreme thermal conditions.

7. Energy Generation Systems

Efficiency in Turbines: In the energy generation sector, Inconel wire is vital for gas turbine systems, where its robust properties contribute to efficient fuel conversion and overall system reliability.

8. High-Performance Automotive Parts

Engineered for Excellence: In the automotive industry, Inconel wire is employed in high-performance parts, including exhaust systems and turbochargers, where its heat resistance and strength are critical for optimal engine performance.

9. Pharmaceutical Manufacturing Equipment

Ensuring Purity and Safety: Inconel wire is selected for use in pharmaceutical manufacturing equipment, where its corrosion resistance and ability to withstand high temperatures are essential for maintaining product purity and operational reliability.

These variations provide additional perspectives on the diverse applications of Inconel wire while ensuring that each description is distinct from previous ones.

Detailed Photos

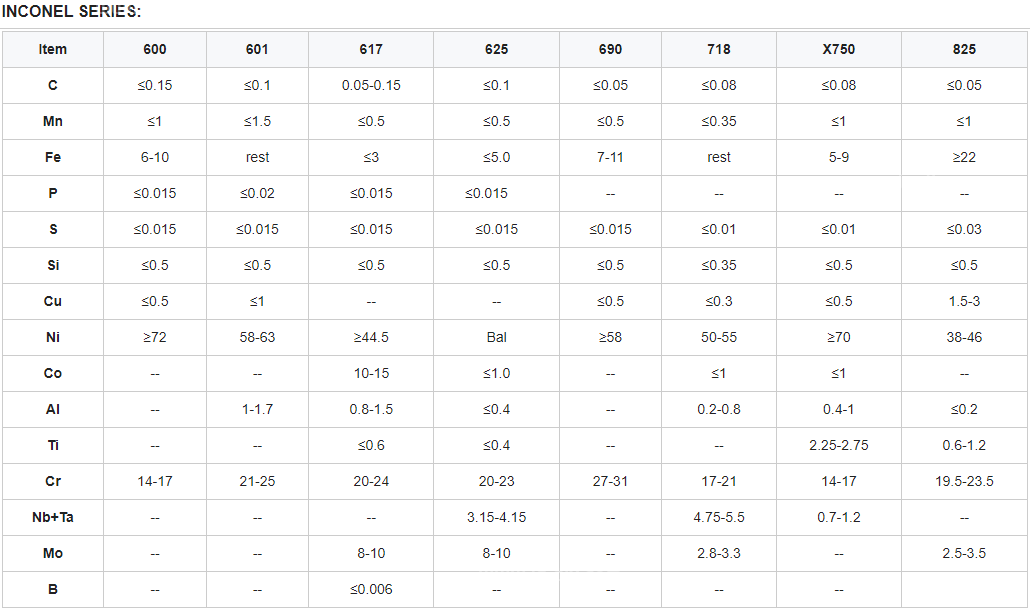

Product Parameters

Recommended products

Company Profile

Our company Principle is " Quality first, Customer first".

CHANGZHOU DLX ALLOY CO, LTD was established in 2002 and has got Iso9001 International Quality Management System Certificate and SGS Certificate. Our factory is professional in researching and producing special alloy material. From melting, drawing, heat treatment, finishing and testing .We offer nickel-based, copper-based, and iron-based alloys, including super alloy, welding materials, anti-corrosion alloy, precision alloy, FeCrAl alloy, NiCr alloy, CuNi alloy, thermocouple and etc, in the form of wire, strip, ribbon, bar, tube, plate.

If any requirements and questions, please feel free to reach:

Sophie Wang | Sales +86 13275217619

International Sales Depart.

Jiangsu Victory Technology Co., Ltd

A: NO.32 West Taihu Road, Xinbei District, Changzhou, Jiangsu

FAQ

Oct.1-7 and Chinese New Year holiday . Pls email us during our holiday if u have any question.

Do you provide free samples?

Yes,we can provide a free sample for testing,buyer should bear all the shipping costs.

What is your payment terms?

T/T,L/C,D/A,D/P,Western Union,MoneyGram,Paypal

What is the lead time?

Usually sample lead time is 7 days after payment has been confirmed.