Product Description

With excellent thermal fatigue resistance, Inconel spring wire is ideal for components subjected to cyclic heating, such as those found in jet engines and industrial furnaces. Its durability helps prevent premature failure in these demanding environments.

Applications

Applications:

Gas Turbines: Inconel spring wire is integral to the functioning of gas turbines, where it is used in components such as turbine blades and seals that require high performance under extreme conditions.

Heat Recovery Steam Generators (HRSG): The alloy is commonly used in HRSG systems, where it must endure high temperatures and pressures while maintaining efficiency and safety.

Combustion Chambers: Inconel is suitable for use in combustion chambers, where it withstands the intense heat generated during fuel combustion.

Advantages:

High-Temperature Performance: Inconel maintains its strength and flexibility at elevated temperatures, making it ideal for high-stress applications in the power generation sector.

Corrosion and Oxidation Resistance: The alloy's ability to resist corrosion and oxidation ensures a longer operational life, reducing maintenance needs and enhancing reliability.

Fatigue Resistance: Its excellent fatigue properties ensure that components can withstand repeated thermal and mechanical stresses, which is crucial for the long-term reliability of power generation systems.

Detailed Photos

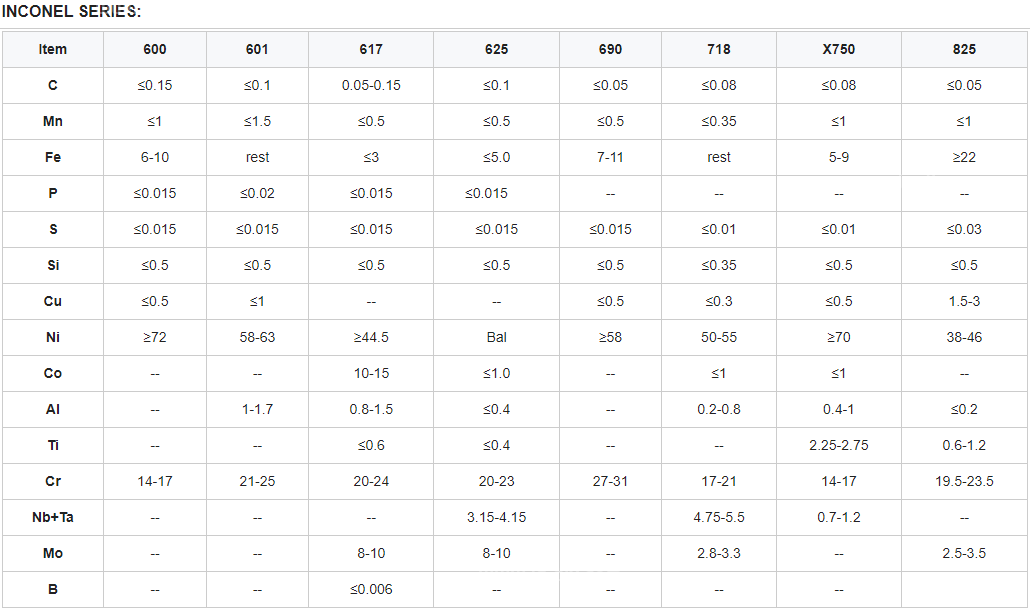

Product Parameters

Recommended products

Company Profile

Our company Principle is " Quality first, Customer first".

CHANGZHOU DLX ALLOY CO, LTD was established in 2002 and has got Iso9001 International Quality Management System Certificate and SGS Certificate. Our factory is professional in researching and producing special alloy material. From melting, drawing, heat treatment, finishing and testing .We offer nickel-based, copper-based, and iron-based alloys, including super alloy, welding materials, anti-corrosion alloy, precision alloy, FeCrAl alloy, NiCr alloy, CuNi alloy, thermocouple and etc, in the form of wire, strip, ribbon, bar, tube, plate.

If any requirements and questions, please feel free to reach:

Sophie Wang | Sales +86 13275217619

International Sales Depart.

Jiangsu Victory Technology Co., Ltd

A: NO.32 West Taihu Road, Xinbei District, Changzhou, Jiangsu

FAQ

Oct.1-7 and Chinese New Year holiday . Pls email us during our holiday if u have any question.

Do you provide free samples?

Yes,we can provide a free sample for testing,buyer should bear all the shipping costs.

What is your payment terms?

T/T,L/C,D/A,D/P,Western Union,MoneyGram,Paypal

What is the lead time?

Usually sample lead time is 7 days after payment has been confirmed.