13-17 µm/mK Thermal Expansion Inconel Alloy Wire with Solid Solution Acid White Surface Finish

Product Description:

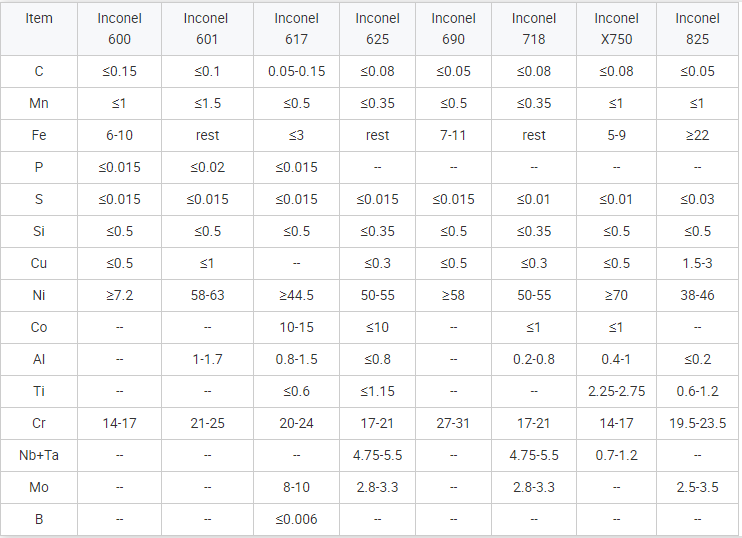

One of the unique properties of the Inconel Alloy is its thermal expansion rate, which is between 13-17 µm/mK. This property makes it an ideal material for high-temperature applications where thermal expansion can cause damage to the structure. The Inconel Alloy is also known for its excellent resistance to corrosion, oxidation, and pitting. It can withstand harsh environments, making it a popular choice for applications where corrosion resistance is critical.

The Inconel Alloy is primarily used as a nickel pipe in various industries, including chemical processing, oil and gas, and power generation. It is available in different sizes and shapes, including round, rectangular, and square. The Inconel Alloy meets the ASTM and ASME standards, ensuring its quality and reliability.

The melting range of the Inconel Alloy is between 1332-1380 ℃, which is higher than most other alloys. This property makes it an excellent choice for high-temperature applications where the material needs to withstand extreme temperatures. The Inconel Alloy is also known for its excellent mechanical properties, including high tensile strength, toughness, and creep resistance.

The Inconel Alloy is widely used in heat exchangers, where it is used to transfer heat from one fluid to another. It is also used in the production of various alloy products, including CuNi alloys. The Inconel Alloy is an essential component in the manufacturing of gas turbines, jet engines, and other high-temperature applications.

In conclusion, the Inconel Alloy is a high-performance alloy steel metal that offers excellent resistance to corrosion, high temperatures, and pressure. It is widely used in various industries, including aerospace, chemical processing, and power generation. The Inconel Alloy is known for its unique properties, including its thermal expansion rate, excellent resistance to corrosion, and high melting range. It meets the ASTM and ASME standards, ensuring its quality and reliability. The Inconel Alloy is an essential component in the manufacturing of various alloy products, including CuNi alloys, and it is widely used in heat exchangers, gas turbines, and jet engines.

Applications:

The DLX Inconel Alloy, also known as Incoloy Alloy 20 Plate Sheet, is a high-performance material that has unique properties that make it ideal for various applications. This alloy is made in China and has been tested for quality assurance to ensure that it meets international standards. The DLX Inconel Alloy is a popular choice for many industries due to its excellent mechanical properties.

One of the most common applications of the DLX Inconel Alloy is Inconel 625 cladding. This process involves applying a layer of Inconel Alloy to a base metal, typically alloy steel, to improve its resistance to corrosion and wear. The DLX Inconel Alloy is an excellent choice for this application due to its high strength and excellent corrosion resistance.

Another common application of the DLX Inconel Alloy is in the production of alloy steel metal. This alloy is often used to produce high-temperature components for the aerospace, oil and gas, and chemical processing industries. The DLX Inconel Alloy is an excellent choice for these applications due to its high-temperature strength and excellent resistance to corrosion and oxidation.

The DLX Inconel Alloy is also commonly used in the production of heat exchangers and other high-temperature equipment. Its high strength and excellent thermal properties, such as its specific heat of 444 J/kg-°C and specific heat capacity of 0.431 J/g-°C, make it an ideal choice for these applications. Additionally, its thermal expansion rate of 13-17 µm/mK ensures that it can withstand extreme temperatures without cracking or warping.

In conclusion, the DLX Inconel Alloy is a versatile material that can be used in a wide range of applications. Its unique properties, including its high strength, excellent corrosion resistance, and thermal stability, make it an ideal choice for industries such as aerospace, oil and gas, and chemical processing.

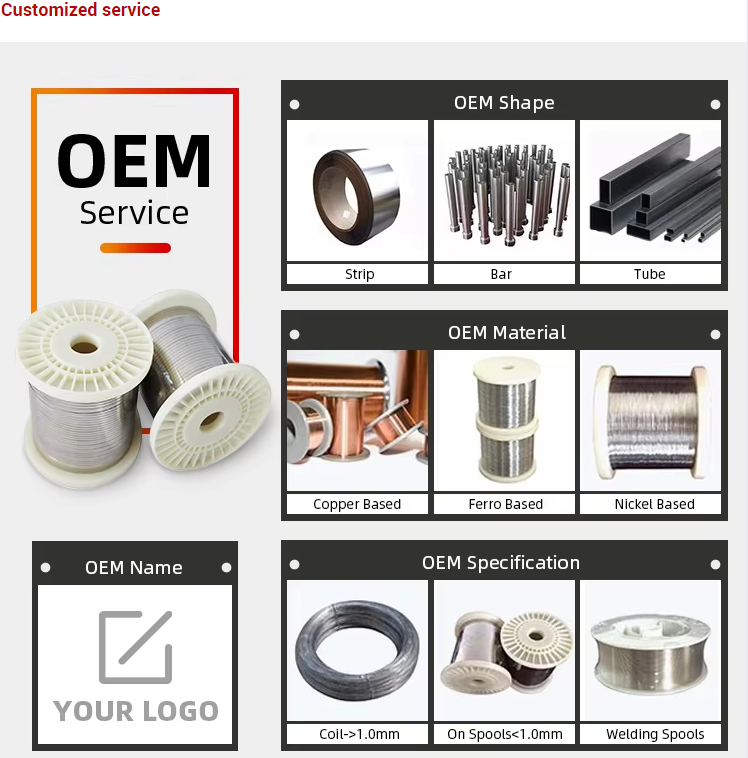

Customization:

With our customization services, you can specify the elongation, which is typically 30%, and the non-magnetic properties of the Inconel Alloy. Additionally, we can tailor the specific heat capacity to your needs at 0.431 J/g-°C. Our Inconel Alloy also has excellent low temperature resistance, with the ability to perform down to -253°C.

Support and Services:

Inconel Alloy is a family of austenitic nickel-chromium-based superalloys that are resistant to oxidation and corrosion at high temperatures.

Our technical support team is available to assist with any questions or concerns you may have about the product, including:

Material selection and properties

Design and engineering recommendations

Welding and fabrication

Machining and finishing

In addition, we offer a variety of services to support our customers' needs, such as:

Custom product development and prototyping

Testing and analysis

Quality control and assurance

Logistics and supply chain management

Our goal is to provide comprehensive technical support and services to ensure the successful use and application of Inconel Alloy in your projects and applications.

Packing and Shipping:

Product: Inconel Alloy

Description: Inconel is a family of austenitic nickel-chromium-based superalloys that are well-suited for extreme environments subjected to pressure and heat. It is often used in aerospace, chemical processing, and marine engineering applications.

Packaging: The Inconel Alloy product will be packaged in a sturdy wooden crate with foam padding to prevent any damage during transportation.

Shipping: The product will be shipped via air or sea freight depending on the customer's preference. We will ensure that the product is properly labeled and all necessary documentation is included for smooth customs clearance.

FAQ:

Here are some frequently asked questions and answers about DLX's Inconel Alloy:

Q: What is DLX's Inconel Alloy?

A: DLX's Inconel Alloy is a family of nickel-chromium-based superalloys used in high-temperature applications.

Q: What are the benefits of using DLX's Inconel Alloy?

A: DLX's Inconel Alloy offers excellent resistance to high temperatures, corrosion, and oxidation. It also has good mechanical properties and is easily fabricated.

Q: Where is DLX's Inconel Alloy manufactured?

A: DLX's Inconel Alloy is manufactured in China.

Q: What is the model number of DLX's Inconel Alloy?

A: The model number for DLX's Inconel Alloy is simply "Inconel Alloy."

Q: What are some common applications for DLX's Inconel Alloy?

A: DLX's Inconel Alloy is commonly used in aerospace, chemical processing, gas turbine components, and other high-temperature applications where corrosion and oxidation resistance are critical.