Welcome to Changzhou DLX Alloy Co., Ltd.

Over 22 years of R&D and manufacturing experience

Product quality is guaranteed After-sales 7×24 hours service

Welcome to Changzhou DLX Alloy Co., Ltd.

Over 22 years of R&D and manufacturing experience

Product quality is guaranteed After-sales 7×24 hours service

Whatsapp:+86 199 0611 9641

Email:sales8@dlx-alloy.com

Add:NO.32 West Taihu Road, Xinbei District, Changzhou, Jiangsu,China

Inconel Strip

Product Details

Product Description

Inconel Strips are engineered for versatility and durability, offering remarkable resistance to both heat and corrosion.

These strips are commonly used in the oil and gas industry for downhole tubing and pipeline applications, where they withstand aggressive environments and high pressures.

Their ability to resist stress corrosion cracking makes them essential for ensuring safe and efficient operations in challenging conditions.

Applications

Inconel Strips: Key Features and Benefits

High-Temperature Endurance: Inconel strips are designed to maintain their structural integrity under extreme heat, making them ideal for aerospace and industrial heating applications.

Outstanding Corrosion Resistance: These strips resist oxidation and corrosion, ensuring durability in harsh environments like chemical processing and marine applications.

Strong Mechanical Properties: With high tensile strength, Inconel strips can handle significant stress, essential for applications in the oil and gas sector.

Fabrication Flexibility: The alloy can be easily shaped into various configurations, accommodating diverse applications from nuclear reactors to automotive components.

Weldable Design: Inconel strips can be welded using standard methods, simplifying integration into complex engineering systems.

Stable Thermal Performance: They maintain reliable performance under varying thermal conditions, crucial for gas turbines and heat exchangers.

Extended Lifespan: Their combination of strength and corrosion resistance ensures a longer service life, reducing the frequency of replacements.

Resistance to Stress Cracking: Inconel strips are engineered to resist stress corrosion cracking, particularly important in high-stress oil and gas operations.

Chemical Resistance: Their ability to withstand aggressive chemicals makes them suitable for various chemical processing applications.

Detailed Photos

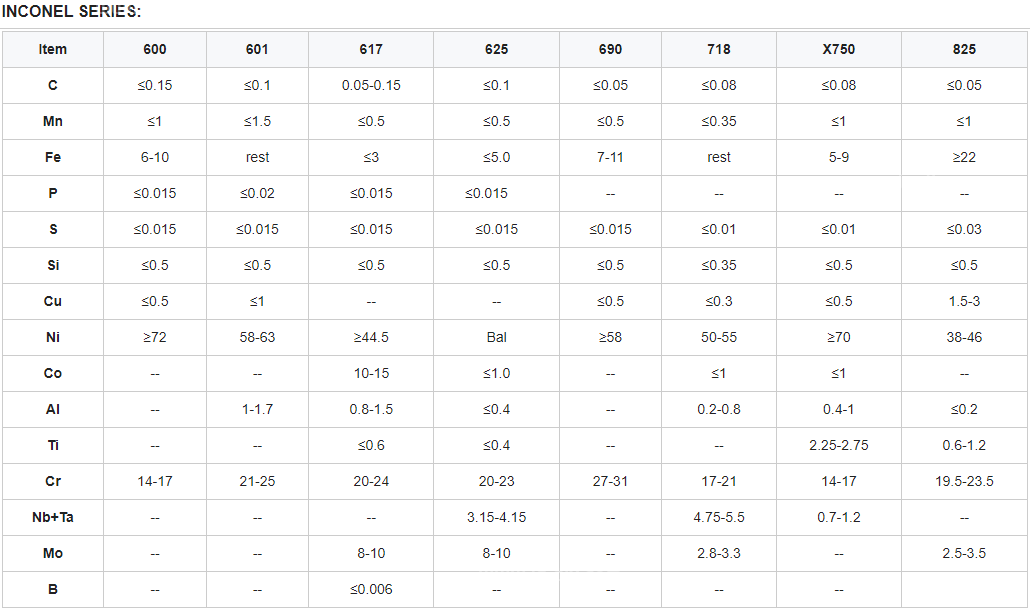

Product Parameters

Recommended products

Company Profile

Our company Principle is " Quality first, Customer first".

CHANGZHOU DLX ALLOY CO, LTD was established in 2002 and has got Iso9001 International Quality Management System Certificate and SGS Certificate. Our factory is professional in researching and producing special alloy material. From melting, drawing, heat treatment, finishing and testing .We offer nickel-based, copper-based, and iron-based alloys, including super alloy, welding materials, anti-corrosion alloy, precision alloy, FeCrAl alloy, NiCr alloy, CuNi alloy, thermocouple and etc, in the form of wire, strip, ribbon, bar, tube, plate.

If any requirements and questions, please feel free to reach:

Sophie Wang | Sales +86 13275217619

International Sales Depart.

Jiangsu Victory Technology Co., Ltd

A: NO.32 West Taihu Road, Xinbei District, Changzhou, Jiangsu

FAQ