Product Description

INCONEL 600 is a nickel-chromium alloy known for its exceptional strength, outstanding corrosion resistance, and reliable performance in high-temperature environments. It is extensively used in industries like chemical processing, aerospace, power generation, and marine due to its superior resistance to oxidation, carburization, and various corrosive substances. INCONEL 600 retains its mechanical properties and structural integrity even under extreme conditions, making it an ideal choice for applications that demand durability and high performance in harsh environments.

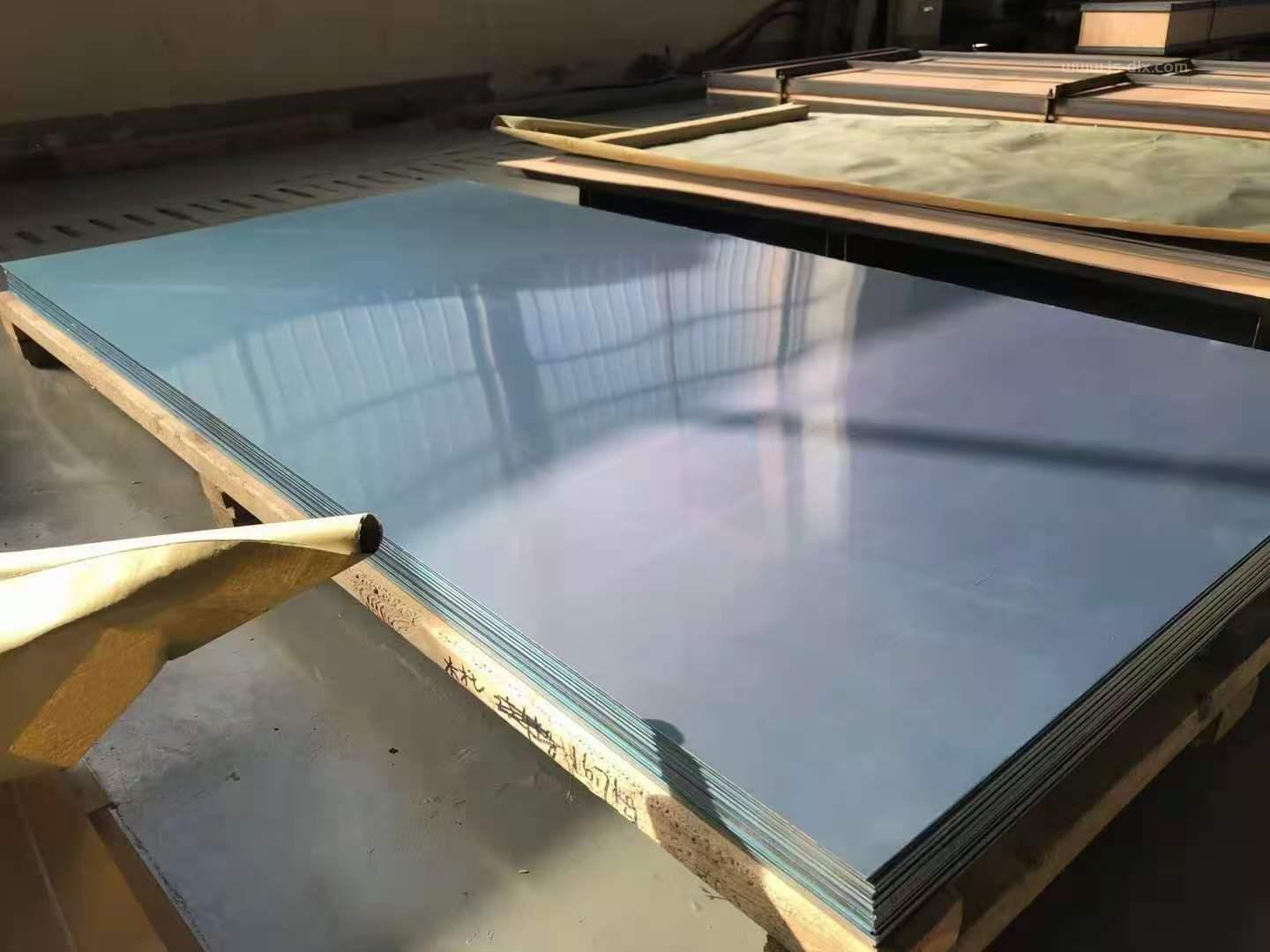

Detailed Photos

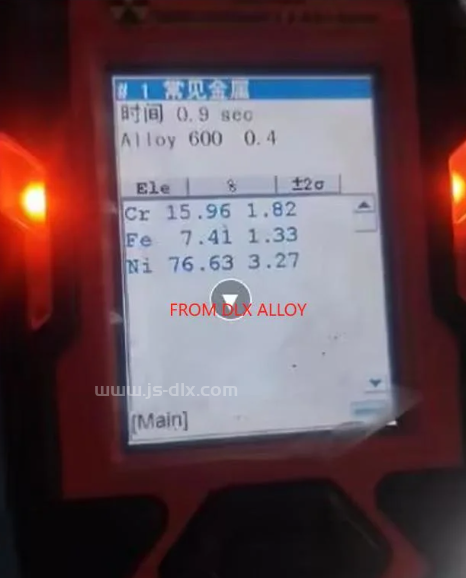

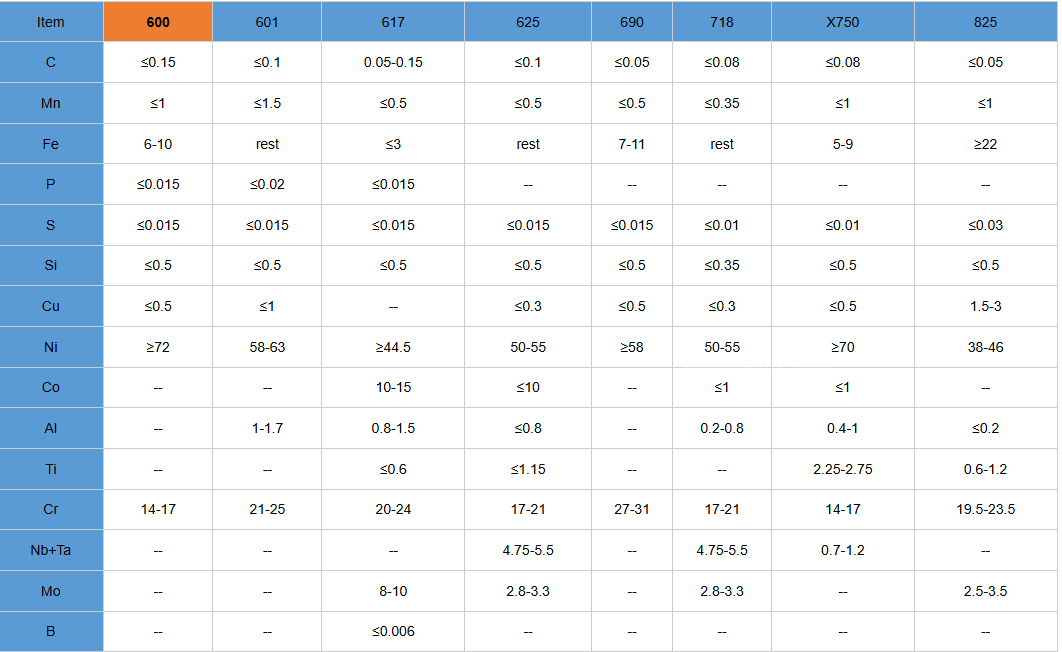

INCONEL 600 is a nickel-chromium alloy composed mainly of around 72% nickel, 14-17% chromium, and 6-10% iron. This specific blend gives the alloy outstanding resistance to oxidation and corrosion across a variety of environments. The high nickel content provides stability and strength at elevated temperatures, while chromium enhances its resistance to oxidation. The addition of iron contributes to the alloy's overall strength and durability, making INCONEL 600 ideal for challenging applications such as chemical processing, aerospace, and power generation.

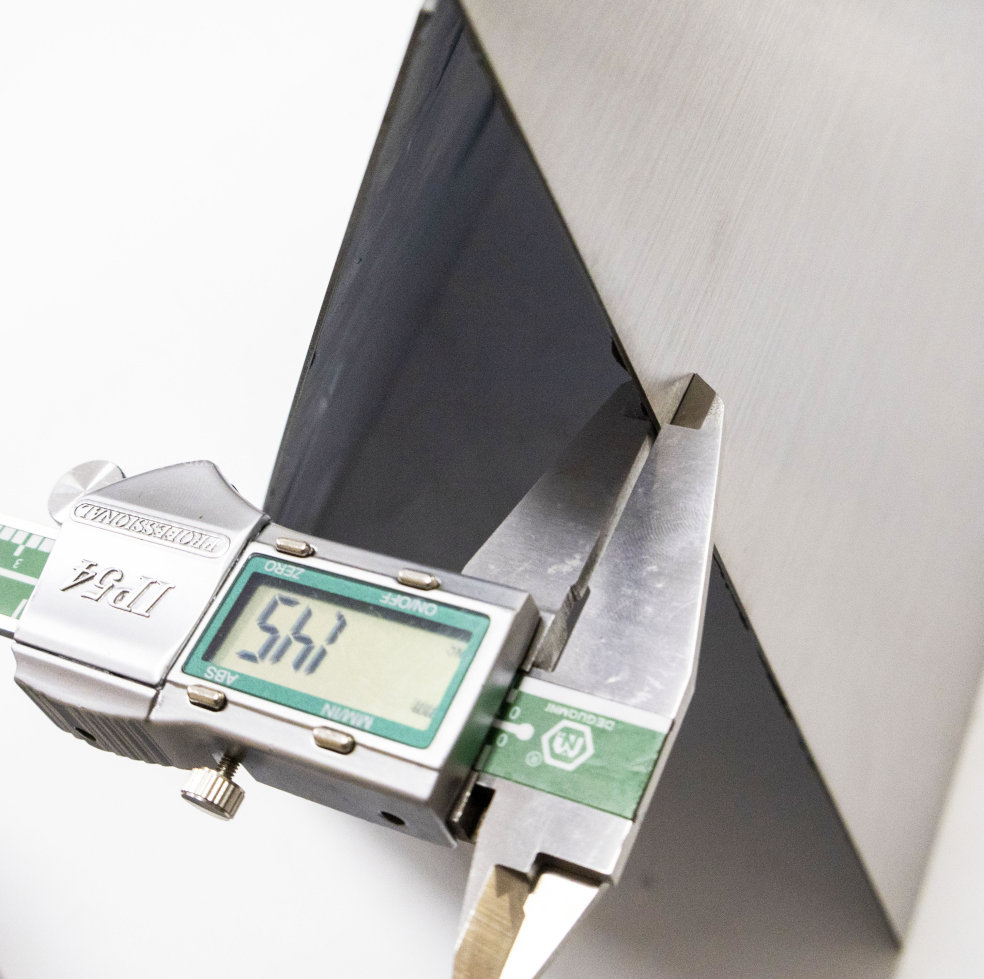

We can adjust the thickness to match your specific requirements. Before shipping, we will send you detailed photos of the measurements to ensure the dimensions meet your expectations. This step allows you to review and confirm the specifications, guaranteeing that the product perfectly aligns with your needs.

To ensure the product arrives in perfect condition, we will securely package it using wooden pallets or crates. This durable packaging method protects the product from damage during transit, giving you confidence and peace of mind that you will receive a high-quality product.

Product Parameters

*High Temperature Resistance:

Inconel Alloys maintain exceptional stability even under extreme heat, making them ideal for high-temperature environments such as aerospace engine components and industrial furnace grates.

*Superior Corrosion Resistance:

Inconel alloys offer outstanding resistance to acidic, alkaline, and other corrosive environments, making them well-suited for applications in the chemical and marine industries.

*High Strength and Durability:

Inconel alloys possess remarkable strength and durability, capable of withstanding high pressure and heavy loads. This makes them ideal for engineering applications that require high-strength materials, such as oil and gas extraction equipment.

*Excellent Machinability:

Inconel alloys are easy to machine and shape, enabling the production of various complex parts through forging, casting, and machining methods. This enhances manufacturing efficiency and flexibility.

*Customizability:

Inconel alloys can be customized to meet specific customer requirements, including alloy compositions, heat treatment processes, and surface treatments, making them suitable for a wide range of industries and applications.

Company Profile

Our company Principle is " Quality first, Customer first".

CHANGZHOU DLX ALLOY CO, LTD was established in 2002 and has got Iso9001 International Quality Management System Certificate and SGS Certificate. Our factory is professional in researching and producing special alloy material. From melting, drawing, heat treatment, finishing and testing .We offer nickel-based, copper-based, and iron-based alloys, including super alloy, welding materials, anti-corrosion alloy, precision alloy, FeCrAl alloy, NiCr alloy, CuNi alloy, thermocouple and etc, in the form of wire, strip, ribbon, bar, tube, plate.

If any requirements and questions, please feel free to reach:

Sophie Wang | Sales +86 13275217619

International Sales Depart.

Jiangsu Victory Technology Co., Ltd

A: NO.32 West Taihu Road, Xinbei District, Changzhou, Jiangsu

FAQ

Oct.1-7 and Chinese New Year holiday . Pls email us during our holiday if u have any question.

Do you provide free samples?

Yes,we can provide a free sample for testing,buyer should bear all the shipping costs.

What is your payment terms?

T/T,L/C,D/A,D/P,Western Union,MoneyGram,Paypal

What is the lead time?

Usually sample lead time is 7 days after payment has been confirmed.