ASME Standard Plate Agent In Steel with Melting Range of 1332-1380 C

Product Description:

Manufactured to meet the strict standards set by ASTM and ASME, Inconel Alloy is designed to deliver reliable performance even under the most demanding conditions. With its high elongation rate of 30%, this alloy product can flex and bend without cracking or breaking, making it an ideal choice for heat exchanger applications where flexibility and durability are crucial.

But that's not all—Inconel Alloy also boasts an impressive specific heat of 444 J/kg-°C, making it a highly efficient heat transfer material that can quickly and effectively move heat away from critical components. And with a specific heat capacity of 0.431 J/g-°C, this alloy product can store and release heat with remarkable precision, helping to ensure consistent performance and temperature control.

Whether you're working in aerospace, chemical processing, or any other industry that demands high-performance alloy products, Inconel Alloy is a top choice. With its exceptional strength, durability, and heat resistance, this alloy steel product is sure to exceed your expectations and deliver reliable performance in even the most challenging environments.

Applications:

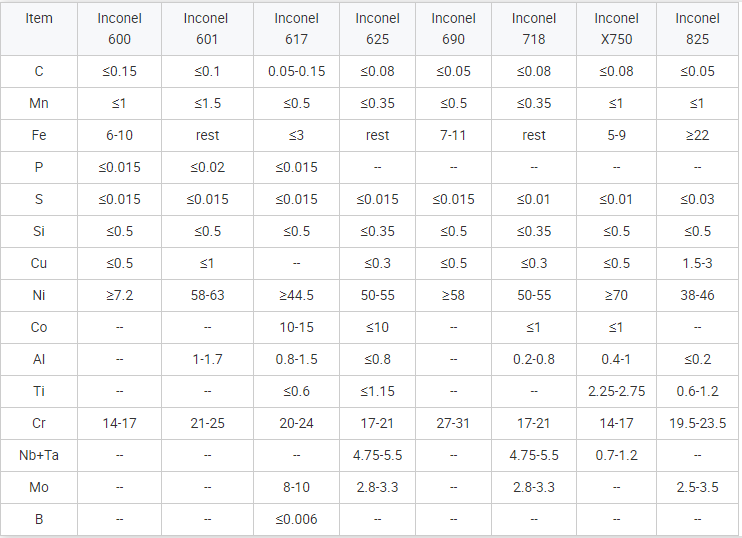

DLX Inconel Alloy is made of Inconel Alloys, which are a family of nickel-chromium-based superalloys known for their excellent mechanical properties, high-temperature strength, and good corrosion resistance. The specific heat capacity of Inconel Alloy is 0.431 J/g-°C, while the specific heat is 444 J/kg-°C. Its yield strength is 310 MPa, which makes it a strong and durable material.

DLX Inconel Alloy is also suitable for use in CuNi Alloy applications. The alloy has excellent resistance to seawater corrosion, making it ideal for use in marine environments. Additionally, Inconel 625 Cladding, a type of Inconel Alloy, is often used in the aerospace industry due to its high strength, excellent resistance to corrosion and oxidation, and its ability to withstand high temperatures.

DLX Inconel Alloy is commonly used in various scenarios, such as oil and gas extraction, chemical processing, and power generation. In the oil and gas industry, Inconel Alloy is used for downhole and surface equipment, as well as in offshore platforms. In chemical processing, Inconel Alloy is used in equipment such as reactors, heat exchangers, and valves. In power generation, Inconel Alloy is used in gas turbine blades, combustion chambers, and exhaust systems.

In conclusion, DLX Inconel Alloy is a versatile material with excellent properties that make it suitable for various applications. Its use in heat exchangers, CuNi Alloy applications, and Inconel 625 Cladding is particularly noteworthy due to its excellent corrosion resistance, high-temperature strength, and durability. Its use in oil and gas extraction, chemical processing, and power generation also highlights its versatility and importance in various industries.

Customization:

Customize your DLX Inconel Alloy product with our product customization services.

Our Inconel Alloy product is a high-performance material that is manufactured in China, with a melting range of 1332-1380 ℃. The Inconel Alloys used in this product provide excellent resistance to corrosion and high-temperature environments. Additionally, the product has a thermal expansion of 13-17 µm/mK and a specific heat capacity of 0.431 J/g-°C, making it a reliable choice for heat exchanger applications.

With our product customization services, we offer Inconel 625 cladding for enhanced protection against corrosion, as well as CuNi Alloy options for improved resistance to thermal stress. Our team of experts can work with you to tailor the product to your specific requirements and applications.

Support and Services:

Our team of technical experts is available to provide support and services for Inconel Alloy products. We offer assistance with product selection, application engineering, and technical troubleshooting.

We also provide customized solutions for specific customer requirements, including design and fabrication of Inconel Alloy components.

Our services include material testing, failure analysis, and product performance evaluation to ensure that our customers receive the highest quality products and support.

Additionally, we offer training and education programs to help our customers optimize the performance and durability of their Inconel Alloy products.

Contact us for more information on how we can support your Inconel Alloy needs.

Packing and Shipping:

Product Packaging:

The Inconel Alloy product will be carefully packed in a sturdy wooden or metal crate to ensure that it is protected during transit. The crate will be lined with foam or other suitable packaging material to prevent any damage to the product.

Shipping:

The Inconel Alloy product will be shipped via a reputable carrier that specializes in the transportation of sensitive and high-value items. We will ensure that the product is properly insured and tracked throughout the shipping process to provide you with peace of mind. Shipping costs will be calculated based on the destination and mode of transportation.

FAQ:

Q: What is the brand name of the Inconel Alloy product?

A: The brand name of the product is DLX.

Q: What is the model number of the Inconel Alloy product?

A: The model number of the product is Inconel Alloy.

Q: Where is the Inconel Alloy product manufactured?

A: The product is manufactured in China.

Q: What are the typical applications of Inconel Alloy?

A: Inconel Alloy is commonly used in high-temperature and corrosive environments, such as gas turbine blades, heat exchangers, and chemical processing equipment.

Q: What are the physical properties of Inconel Alloy?

A: Inconel Alloy has high strength, good resistance to corrosion and oxidation, and excellent toughness at both low and high temperatures.

About: