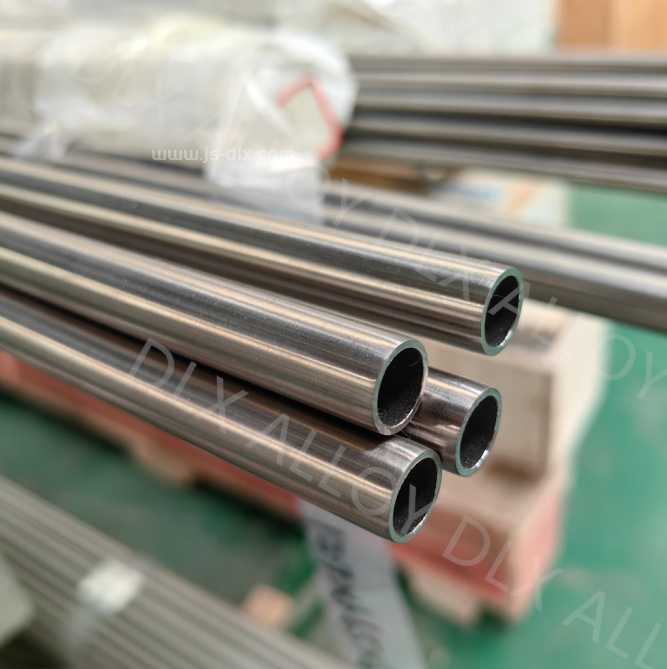

Products Description:

Inconel 825 pipes are made from a nickel-iron-chromium alloy with additions of molybdenum, copper, and titanium. This composition provides excellent resistance to both reducing and oxidizing acids, as well as to stress-corrosion cracking and localized attack such as pitting and crevice corrosion. Known for their superior mechanical properties and stability across a wide range of temperatures, Inconel 825 pipes are ideal for demanding applications in various industries.

Key Features:

Corrosion Resistance: Exceptional resistance to sulfuric and phosphoric acids, as well as to seawater and marine atmospheres.

High Strength: Maintains excellent mechanical properties at both room and elevated temperatures.

Versatility: Suitable for use in a variety of industries, including chemical processing, oil and gas, pollution control, and marine applications.

Durability: Designed to withstand severe service conditions, ensuring long-lasting performance and reliability.

Applications:

Chemical Processing: Ideal for handling acids and other corrosive substances in reactors, heat exchangers, and piping systems.

Oil and Gas: Used in equipment exposed to harsh, corrosive environments, such as offshore platforms and pipelines.

Pollution Control: Suitable for components in flue gas scrubbers and other pollution control equipment.

Marine Engineering: Excellent resistance to seawater and marine atmospheres makes it perfect for offshore and shipboard applications.

Nuclear Industry: Used in nuclear fuel reprocessing and handling due to its resistance to radiation and corrosion.

Specifications:

Diameter Range: Available in various diameters to meet specific application requirements.

Length: Customizable lengths to suit project needs.

Standards: Meets ASTM B423 and other relevant industry standards.

About Us:

JIANGSU DLX TECHNOLOGY CO, LTD was established in 2002 and has got Iso9001 International Quality Management System Certificate and SGS Certificate. Our factory is professional in researching and producing special alloy material. From melting, drawing, heat treatment, finishing and testing .We offer nickel-based, copper-based, and iron-based alloys, including super alloy, welding materials, anti-corrosion alloy, precision alloy, FeCrAl alloy, NiCr alloy, CuNi alloy, thermocouple and etc, in the form of wire,strip, ribbon, bar, tube, plate.

Why Choose Inconel 825 Pipes:Inconel 825 pipes offer a combination of high performance, durability, and resistance to extreme conditions that is unmatched by many other materials. Whether for high-stress industrial applications or environments with severe corrosion challenges, Inconel 825 pipes deliver reliable and efficient solutions.

Frequently Asked Questions (FAQ) about Inconel 825 Pipes

Q1: What is Inconel 825?

A1: Inconel 825 is a nickel-iron-chromium alloy with additions of molybdenum, copper, and titanium. It is designed to provide exceptional resistance to various corrosive environments, including both oxidizing and reducing conditions.

Q2: What are the key properties of Inconel 825 pipes?

A2: Inconel 825 pipes exhibit excellent resistance to both general and localized corrosion, including pitting and crevice corrosion. They offer high resistance to sulfuric and phosphoric acids, as well as stress-corrosion cracking. Additionally, Inconel 825 maintains good mechanical properties across a wide range of temperatures.

Q3: What applications are Inconel 825 pipes commonly used for?

A3: Inconel 825 pipes are commonly used in industries such as chemical processing, oil and gas, pollution control, nuclear fuel reprocessing, acid production, and pickling equipment. Their resistance to harsh environments makes them ideal for use in these applications.

Q4: How do Inconel 825 pipes compare to other Inconel Alloys, like Inconel 625 and 718?

A4: While Inconel 625 and 718 also provide excellent corrosion resistance and mechanical properties, Inconel 825 is specifically designed for enhanced resistance to sulfuric and phosphoric acids. Inconel 625 is more suited for applications requiring high strength and resistance to oxidation at elevated temperatures, whereas Inconel 718 is used for its excellent mechanical properties and ability to withstand extreme temperatures.

Q5: Can Inconel 825 pipes be welded?

A5: Yes, Inconel 825 pipes can be welded using common welding techniques such as gas tungsten arc welding (GTAW), gas metal arc welding (GMAW), and shielded metal arc welding (SMAW). It is important to follow proper welding procedures to avoid issues like hot cracking and to ensure the integrity of the welded joints.

Q6: Are there any specific considerations for machining Inconel 825 pipes?

A6: Machining Inconel 825 can be challenging due to its high strength and work-hardening properties. It is recommended to use high-quality, sharp cutting tools, low cutting speeds, and adequate cooling to prevent work hardening and tool wear. Using carbide-tipped tools can also improve machining performance.

Q7: How does the cost of Inconel 825 pipes compare to other materials?

A7: Inconel 825 pipes are generally more expensive than standard stainless steels due to their high nickel and molybdenum content. However, their superior corrosion resistance and mechanical properties can result in longer service life and reduced maintenance costs, making them a cost-effective choice for demanding applications.

Q8: What are the available sizes and forms of Inconel 825 pipes?

A8: Inconel 825 pipes are available in a variety of sizes, ranging from small diameter tubes to large diameter pipes. They can be supplied in seamless or welded forms, depending on the specific requirements of the application.