Solid Solution Acid White Inconel 625 Pipe

Inconel 625 Pipe Product Description:

The Inconel Alloy is known for its low temperature resistance down to -253°C, making it a reliable choice for applications that require high performance in extreme cold. It is also known for its excellent corrosion resistance, making it a popular choice for use in chemical processing and oil and gas applications.

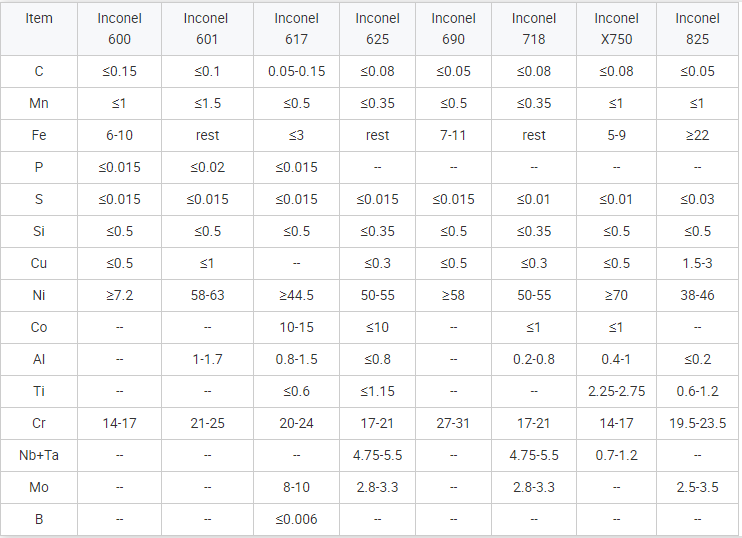

The Inconel Alloy is available in various forms including Inconel 625 Cladding, which is a common choice for cladding applications due to its excellent resistance to corrosion and high strength. This product is made up of a combination of nickel, chromium, and molybdenum, which provides it with excellent strength and durability.

The Inconel Alloy is manufactured in compliance with ASTM and ASME standards, ensuring that it meets the highest quality standards. The melting range of this product is 1332-1380 ℃, which makes it suitable for use in a variety of high-temperature applications.

Overall, the Inconel Alloy is a reliable and high-performance alloy steel product that is widely used in a variety of industrial applications. Its excellent strength, corrosion resistance, and low-temperature resistance make it a popular choice for use in harsh environments. Whether you require Inconel 625 Cladding or any other form of Inconel Alloy, you can trust that this product will meet your needs and exceed your expectations.

Inconel 625 is a nickel-chromium-molybdenum alloy with exceptional strength and corrosion resistance. It is known for its remarkable toughness and ability to withstand high-stress environments, including extreme temperatures and corrosive conditions. The addition of molybdenum and niobium gives it high strength without the need for heat treatment, and its resistance to various corrosive media makes it a popular choice in several demanding industries.

Key Characteristics of Inconel 625:

Corrosion Resistance: Excellent resistance to a wide range of corrosive environments, including seawater, acidic environments, and oxidation. It resists pitting, crevice corrosion, and stress-corrosion cracking.

Temperature Stability: Performs well at both low temperatures and high temperatures, up to 982°C (1800°F).

Strength and Ductility: High tensile strength, fatigue strength, and creep resistance, allowing it to withstand extreme mechanical stress without losing toughness.

Weldability: Can be welded with ease without post-weld heat treatment, maintaining excellent resistance to cracking.

Applications:

Marine and Offshore: Inconel 625 is widely used in marine environments, including seawater equipment and offshore oil and gas industries due to its outstanding resistance to saltwater corrosion.

Aerospace: It is used in jet engine components, exhaust systems, and other high-temperature, high-stress aerospace applications.

Chemical Processing: Inconel 625 is ideal for handling corrosive chemicals, acids, and high-temperature environments in the chemical processing industry.

Nuclear Industry: It is used in nuclear reactors and other critical applications that require high strength and corrosion resistance

One of the most common applications for DLX Inconel Alloy is in heat exchangers. The specific heat capacity of 0.431 J/g-°C makes it an ideal choice for heat transfer applications. Heat exchangers are used in several industries, including chemical processing, power generation, and oil and gas refining.

The non-magnetic properties of the DLX Inconel Alloy make it an excellent choice for applications where magnetic interference is a concern. This property makes it an ideal choice for use in electronic and communication devices.

The Alloy Products manufactured by DLX are highly durable, resistant to corrosion and oxidation, and have high-temperature strength. These attributes make DLX Inconel Alloy an ideal choice for use in the aerospace industry. It is used in aircraft engines, gas turbine components, and other high-temperature applications.

Another application of the DLX Inconel Alloy is in the chemical industry. The Alloy Steel Product is used in the production of chemical processing equipment such as reactors, distillation columns, and heat exchangers. It is also used in the manufacturing of catalysts, which are used in the production of chemicals.

DLX Inconel Alloy is also used in the marine industry. The Alloy Steel Metal is highly resistant to corrosion and is used in the manufacturing of marine exhaust systems, seawater piping, and other marine-related applications.

In summary, DLX Inconel Alloy is a versatile Alloy Product that finds application in various industries. Its thermal expansion, non-magnetic properties, and specific heat capacity make it an ideal choice for heat transfer applications. Its durability, resistance to corrosion and high-temperature strength make it an ideal choice for aerospace applications. Its resistance to corrosion makes it an excellent choice for marine applications.

Support and Services:

Inconel Alloy is a family of nickel-chromium-based superalloys that are resistant to high temperatures and corrosion. We offer a range of technical support and services to ensure that our customers get the most out of their Inconel Alloy products:

- Material selection assistance

- Product design and development support

- Technical consultation for manufacturing and processing

- Testing and inspection services

- Failure analysis and troubleshooting

- Customized solutions and product optimization

Our team of experts is dedicated to providing excellent customer service and ensuring that our customers have the knowledge and resources they need to succeed. Contact us today to learn more about our technical support and services for Inconel Alloy.

Packing and Shipping:

Product Name: Inconel Alloy

Quantity: 1 kilogram

Dimensions: 10 cm x 10 cm x 10 cm

Weight: 2 kilograms

Package Contents: Inconel Alloy product securely packed in a plastic bag and placed in a cardboard box with bubble wrap padding

Shipping Method: Standard Shipping

Shipping Address: Please provide a valid shipping address

About Us:

Our company Principle is " Quality first, Customer first".

CHANGZHOU DLX ALLOY CO, LTD was established in 2002 and has got Iso9001 International Quality Management System Certificate and SGS Certificate. Our factory is professional in researching and producing special alloy material. From melting, drawing, heat treatment, finishing and testing .We offer nickel-based, copper-based, and iron-based alloys, including super alloy, welding materials, anti-corrosion alloy, precision alloy, FeCrAl alloy, NiCr alloy, CuNi alloy, thermocouple and etc, in the form of wire, strip, ribbon, bar, tube, plate.

FAQ:

Q: What is the brand name of this product?

A: The brand name of this product is DLX.

Q: What is the model number of this product?

A: The model number of this product is Inconel Alloy.

Q: Where is this product made?

A: This product is made in China.

Q: What are the key features of this product?

A: This product is made of Inconel Alloy, which is known for its excellent resistance to high temperatures, corrosion, and oxidation. It is also highly durable and has excellent strength and toughness.

Q: What are some common applications of this product?

A: This product is commonly used in high-temperature applications such as gas turbines, heat exchangers, and industrial furnaces. It is also used in the aerospace industry for engine components and structural parts.