Inconel 601 607 Pipe with 310 MPa Yield Strength and 30% Elongation

Inconel 601 607 Pipe Product Description:

Product Description:

One of the key features of this product is its non-magnetic properties. This makes it an excellent choice for applications where magnetic interference could be a problem, such as in electronics or scientific research. Additionally, the Inconel Alloy Steel Metal product has a melting range of 1332-1380 ℃, making it a highly heat-resistant choice for high-temperature applications.

Another important attribute of this product is its impressive yield strength of 310 MPa. This means that it is able to withstand a significant amount of stress and pressure without experiencing deformation or damage. This makes it an ideal choice for applications where strength and durability are critical.

Overall, the Inconel Alloy Steel Metal product is a top-of-the-line choice for a variety of industrial applications. With its non-magnetic properties, high heat resistance, and impressive yield strength, it is a versatile and reliable choice for any project. So why wait? Order yours today!

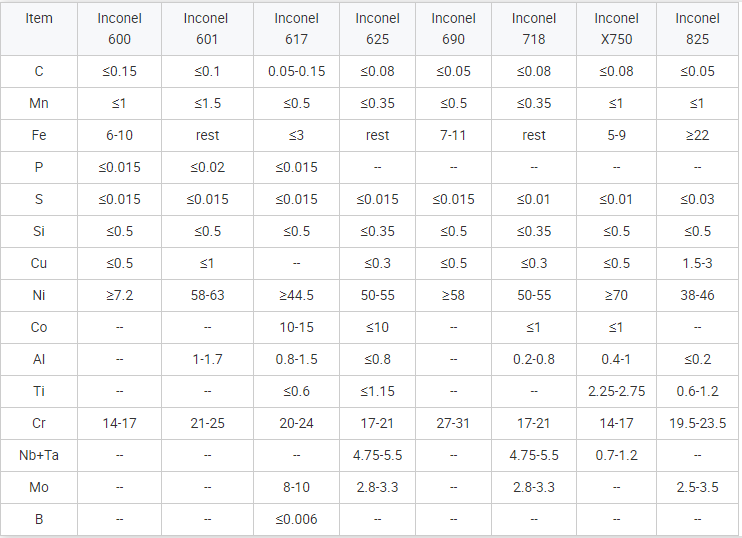

Inconel 601 and Inconel 607 are both high-performance nickel-based alloys, designed for use in extreme environments where resistance to heat and corrosion is critical.

Inconel 601:

Inconel 601 is a nickel-chromium alloy known for its excellent oxidation resistance at high temperatures, up to 1200°C (2200°F). It has good resistance to aqueous corrosion and strong mechanical properties even in extreme heat. The addition of aluminum gives it excellent resistance to oxidation, making it highly suitable for heat treatment and thermal processing industries.

Key Features:

Superior oxidation resistance at high temperatures.

High mechanical strength and toughness.

Good resistance to carburization and sulfur-containing environments.

Applications include thermal reactors, radiant tubes, heat-treating equipment, and gas turbine components.

Inconel 607:

Inconel 607 is another nickel-chromium alloy with similar high-temperature oxidation resistance, but it also contains small additions of cobalt and molybdenum, which enhance its strength and stability at extreme temperatures. This alloy is particularly useful in applications that require superior creep resistance and long-term thermal stability.

Key Features:

Excellent resistance to oxidation and thermal fatigue.

Superior strength at high temperatures.

Improved creep and stress-rupture properties.

Applications include furnace hardware, gas turbine components, and petrochemical processing equipment.

Applications:

The Inconel Alloy by DLX is widely used in various industries due to its exceptional properties. One of its popular applications is Inconel 625 cladding. It is commonly used in the manufacturing of vessels and tanks that require high strength and corrosion resistance. Inconel 625 cladding provides protection against corrosion and maintains the integrity of the vessel or tank.

Inconel Alloy is also used in the aerospace industry for its high-temperature strength and excellent resistance to oxidation and corrosion. It is used in the manufacturing of aircraft engines, exhaust systems, and structural components that require high strength and durability. The Inconel Alloy by DLX is an ideal choice for these applications due to its exceptional mechanical properties.

Another common application of the Inconel Alloy is in the chemical processing industry. It is used in the manufacturing of equipment that requires resistance to corrosive environments, such as chemical reactors, distillation columns, and heat exchangers. The Inconel Alloy by DLX provides excellent resistance to a wide range of corrosive environments and can withstand high temperatures and pressures.

The Inconel Alloy by DLX is also used in the oil and gas industry. It is used in the manufacturing of oil well equipment such as tubing, casing, and downhole tools. The Inconel Alloy provides excellent resistance to high-pressure and high-temperature environments, making it an ideal choice for these applications.

In conclusion, DLX's Inconel Alloy is a versatile product that is widely used in various industries. Its exceptional properties make it an ideal choice for Inconel 625 cladding, aerospace, chemical processing, and oil and gas industry applications. With its excellent resistance to corrosion and high-temperature strength, the Inconel Alloy by DLX is a reliable and durable product that delivers exceptional performance.

Both Inconel 601 and 607 are used in industries that demand durable materials capable of withstanding harsh operating conditions, including high-temperature exposure, corrosive environments, and mechanical stress.

Customization:

Customize your DLX Inconel Alloy product with our product customization services. Our Inconel Alloy product is made in China and is designed for high performance in extreme environments. The product features Inconel 625 cladding and is made from alloy steel metal, making it a reliable and durable choice for your needs.

Our customization services allow you to tailor your product to meet your specific requirements. Choose from a range of thermal expansion options between 13-17 µm/mK, specific heat capacity of 0.431 J/g-°C, standard ASTM and ASME, and a yield strength of 310 MPa. In addition, our Inconel Alloy product has low temperature resistance down to -253°C, making it a great choice for applications in extreme temperatures.

Whether you need an alloy agent in steel or a high-performance material for your project, our DLX Inconel Alloy product can be customized to meet your needs. Contact us today to learn more about our product customization services.

Support and Services:

Our Product Technical Support and Services for Inconel Alloy include:

- Material selection assistance

- Technical consultation on design and manufacturing

- Material testing and analysis

- Customized material development and prototyping

- Troubleshooting and failure analysis

- On-site technical support and training

Packing and Shipping:

Product Packaging:

The Inconel Alloy product will be packed in wooden boxes or crates.

The boxes or crates will be properly sealed and labeled for easy identification.

Each box or crate will contain a packing list to ensure accuracy of contents.

Product Shipping:

The Inconel Alloy product will be shipped via air, sea, or ground transportation depending on the customer's preference and urgency of delivery.

The product will be shipped in accordance with all relevant regulations and requirements.

The customer will be provided with a tracking number to monitor the shipment's progress.

About Us:

Our company Principle is " Quality first, Customer first".

CHANGZHOU DLX ALLOY CO, LTD was established in 2002 and has got Iso9001 International Quality Management System Certificate and SGS Certificate. Our factory is professional in researching and producing special alloy material. From melting, drawing, heat treatment, finishing and testing .We offer nickel-based, copper-based, and iron-based alloys, including super alloy, welding materials, anti-corrosion alloy, precision alloy, FeCrAl alloy, NiCr alloy, CuNi alloy, thermocouple and etc, in the form of wire, strip, ribbon, bar, tube, plate.

FAQ:

Q: What is DLX Inconel Alloy?

A: DLX Inconel Alloy is a high-performance nickel-chromium alloy that offers excellent resistance to oxidation and corrosion in high-temperature environments.

Q: What are the applications of DLX Inconel Alloy?

A: DLX Inconel Alloy is widely used in aerospace, chemical processing, gas turbine components, nuclear reactors, and other high-temperature applications.

Q: What are the benefits of using DLX Inconel Alloy?

A: DLX Inconel Alloy offers high strength, excellent resistance to corrosion and oxidation, and good creep and rupture strength at high temperatures, making it an ideal choice for demanding applications in harsh environments.

Q: Where is DLX Inconel Alloy manufactured?

A: DLX Inconel Alloy is manufactured in China, where the production process is closely monitored to ensure consistent quality and performance.

Q: What are the different forms of DLX Inconel Alloy available?

A: DLX Inconel Alloy is available in various forms, including bars, sheets, plates, pipes, and tubes, which can be customized to meet specific requirements.