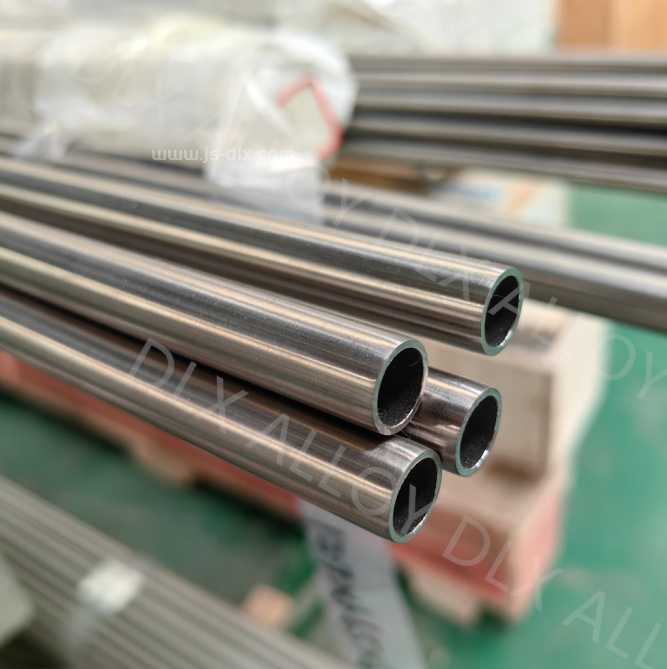

Products Description:

Inconel 718 pipes are made from a high-strength, nickel-chromium alloy that combines excellent corrosion resistance with superior mechanical properties. Designed to withstand extreme temperatures and

harsh environments, these pipes are ideal for demanding applications across various industries.

Key Features:

High-Temperature Strength: Inconel 718 pipes retain their strength and structural integrity at temperatures up to 700°C (1290°F).

Corrosion Resistance: Exceptional resistance to oxidation, pitting, and crevice corrosion in both acidic and alkaline environments.

Creep and Stress Rupture Resistance: Outstanding resistance to creep and stress rupture at high temperatures, ensuring long-term performance.

Versatility: Suitable for a wide range of applications, from aerospace and power generation to chemical processing and marine engineering.

Applications:

Aerospace: Ideal for turbine engines, compressor blades, and other high-temperature components.

Power Generation: Used in gas turbines, heat exchangers, and nuclear reactors.

Chemical Processing: Suitable for handling corrosive substances in reactors, heat treatment equipment, and other processing units.

Marine Engineering: Excellent resistance to seawater and marine atmospheres, making it perfect for offshore and maritime applications.

Specifications:

Diameter Range: Available in various diameters to meet specific application requirements.

Length: Customizable lengths to suit project needs.

Standards: Meets ASTM B163, B167, B407, B409, and other relevant industry standards.

Why Choose Inconel 718 Pipes:Inconel 718 pipes offer a unique combination of high strength, corrosion resistance, and durability, making them the go-to solution for critical applications in extreme environments. Whether for aerospace, power generation, or chemical processing, Inconel 718 pipes deliver reliable and efficient performance.

About US:JIANGSU DLX TECHNOLOGY CO, LTD was established in 2002 and has got Iso9001 International Quality Management System Certificate and SGS Certificate. Our factory is professional in researching and producing special alloy material. From melting, drawing, heat treatment, finishing and testing .We offer nickel-based, copper-based, and iron-based alloys, including super alloy, welding materials, anti-corrosion alloy, precision alloy, FeCrAl alloy, NiCr alloy, CuNi alloy, thermocouple and etc, in the form of wire,strip, ribbon, bar, tube, plate.

Inconel 718 Pipes - FAQ

1. What is Inconel 718?

Inconel 718 is a nickel-chromium alloy known for its excellent mechanical properties, high strength, and remarkable resistance to corrosion, oxidation, and high temperatures. It is widely used in extreme environments where reliability and durability are critical.

2. What are the key properties of Inconel 718 pipes?

High strength and durability at temperatures up to 700°C (1290°F)

Exceptional resistance to oxidation and corrosion

Superior creep and stress rupture resistance

Excellent weldability and fabricability

3. What industries use Inconel 718 pipes?

Inconel 718 pipes are used in aerospace, power generation, chemical processing, marine engineering, and other industries that require materials capable of withstanding extreme temperatures and corrosive environments.

4. What sizes and forms are available for Inconel 718 pipes?

Inconel 718 pipes are available in various diameters and lengths to meet specific application requirements. Custom sizes can be provided to suit particular project needs.

5. What standards do Inconel 718 pipes meet?

Inconel 718 pipes meet ASTM B163, B167, B407, B409, and other relevant industry standards, ensuring high quality and performance.

6. How do Inconel 718 pipes perform in high-temperature environments?

Inconel 718 pipes maintain their strength and structural integrity at high temperatures, making them suitable for applications that involve extreme heat and thermal cycling.

7. Are Inconel 718 pipes resistant to corrosion?

Yes, Inconel 718 pipes offer excellent resistance to oxidation, pitting, crevice corrosion, and a wide range of corrosive media, including both acidic and alkaline environments.

8. What are the common applications of Inconel 718 pipes?

Common applications include turbine engines, compressor blades, gas turbines, heat exchangers, nuclear reactors, chemical reactors, and marine components exposed to seawater and marine atmospheres.

9. How should Inconel 718 pipes be stored and handled?

Inconel 718 pipes should be stored in a clean, dry environment to prevent contamination. Proper handling techniques should be employed to avoid surface damage and maintain their high-performance properties.