Product Description

Known for their outstanding corrosion resistance, Inconel 625 coils excel in harsh environments where they encounter aggressive chemicals. This nickel alloy preserves its strength at elevated temperatures and exhibits remarkable durability, making it a top choice for aerospace and energy production applications. Its resilience in extreme conditions guarantees the dependable and safe performance of vital components.

Differences between nickel-based welded pipes and coils

1. Design Characteristics

- Welded Pipes: Typically straight and cylindrical, designed primarily for transporting fluids or gases.

- Coils: Defined by their curved or helical structure, often used in heat exchangers or applications needing adaptability.

2. Production Method

- Welded Pipes: Manufactured by joining flat nickel-based alloy sheets into a tubular shape.

- Coils: Created by bending nickel alloys into coiled forms, making them easier to install in tight spaces.

3. Usage Scenarios

- Welded Pipes: Commonly found in the oil and gas industry, chemical processing, and construction for fluid conveyance.

- Coils: Typically employed in heat exchange systems, refrigeration, and other contexts that require flexibility.

4. Physical Properties

- Welded Pipes: Generally exhibit high strength and rigidity, making them suitable for high-pressure applications.

- Coils: Often provide increased flexibility and lighter weight, which can facilitate handling in various installations.

Detailed Information

To analyze the strength and durability of Inconel 625 coils, we perform water pressure testing. This method entails filling the coils with water and progressively increasing the pressure to evaluate their capacity to withstand severe conditions without leaks. The process involves several steps:

Initial Inspection: Coils are meticulously checked and cleaned to remove any defects.

Sealing: Both ends are tightly sealed to prevent any water from escaping during the test.

Water Filling: The coils are filled with water, ensuring complete removal of air for accurate pressure readings.

Pressure Testing: The pressure is gradually raised to specified levels, often exceeding normal operational limits for a thorough assessment.

Monitoring Phase: Pressure levels are continuously monitored, with any leaks or deformations recorded.

Post-Test Examination: After testing, coils are examined for damage to ensure they meet required safety and performance standards.

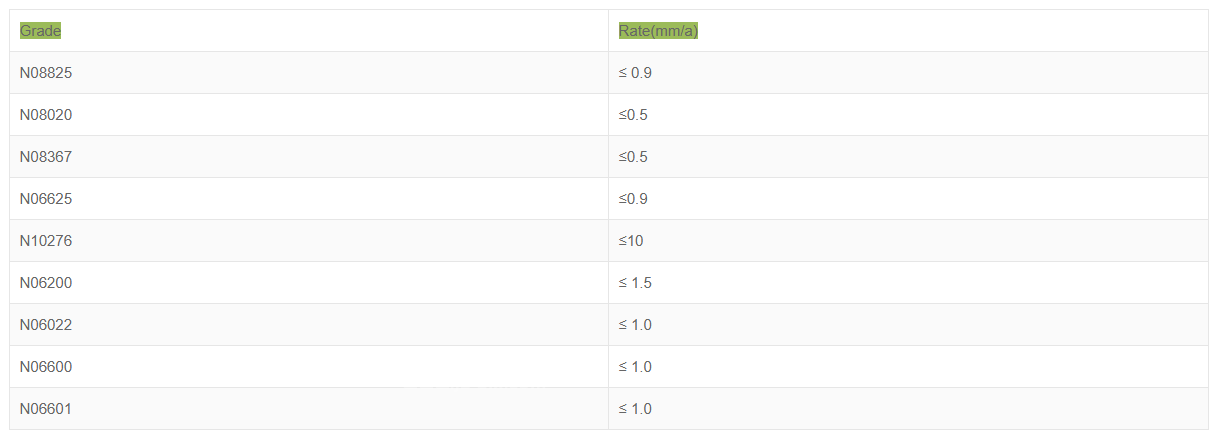

Corrosion Resistance Of Different Materials(G28 A Methord)

DLX ALLOY has advanced equipment, proven techniques, and professional teams. We strictly implement the Quality Management System and API Requirements to ensure that the quality meets the needs of the site. The tests like, NDT | X-ray | Tension test | Hydrostatic test

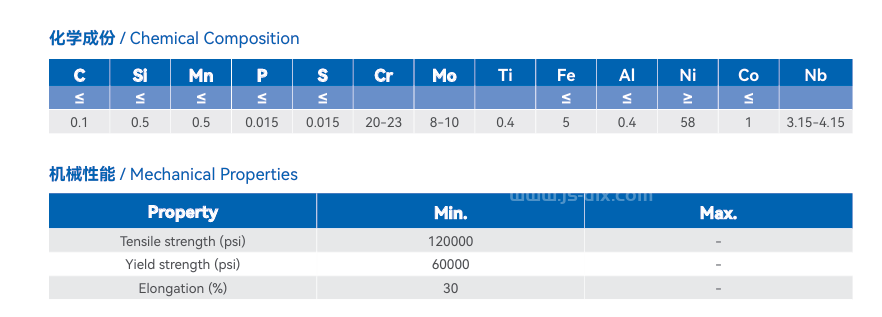

Product Parameters

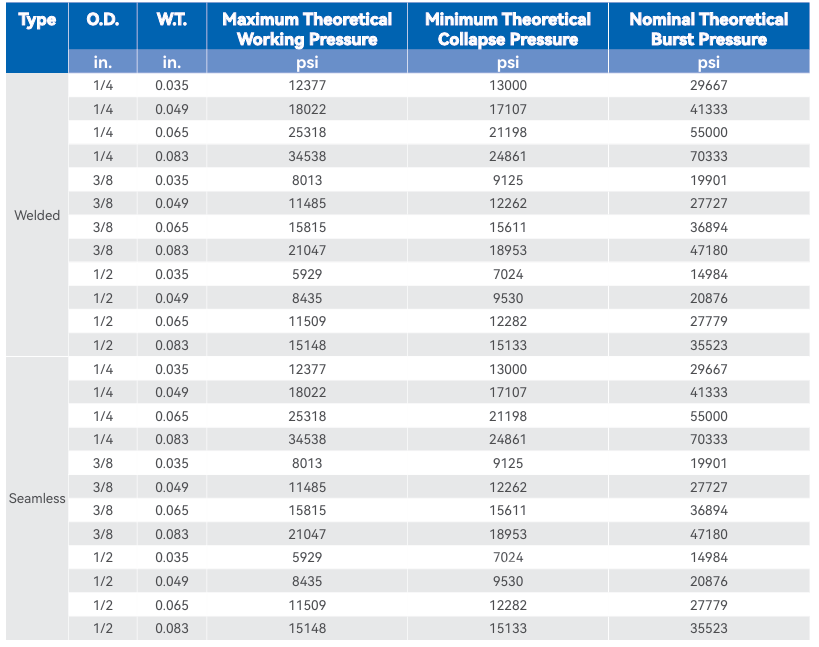

Size Dependant Characteristics (Based Upon Nominal Tubing Dimensions)

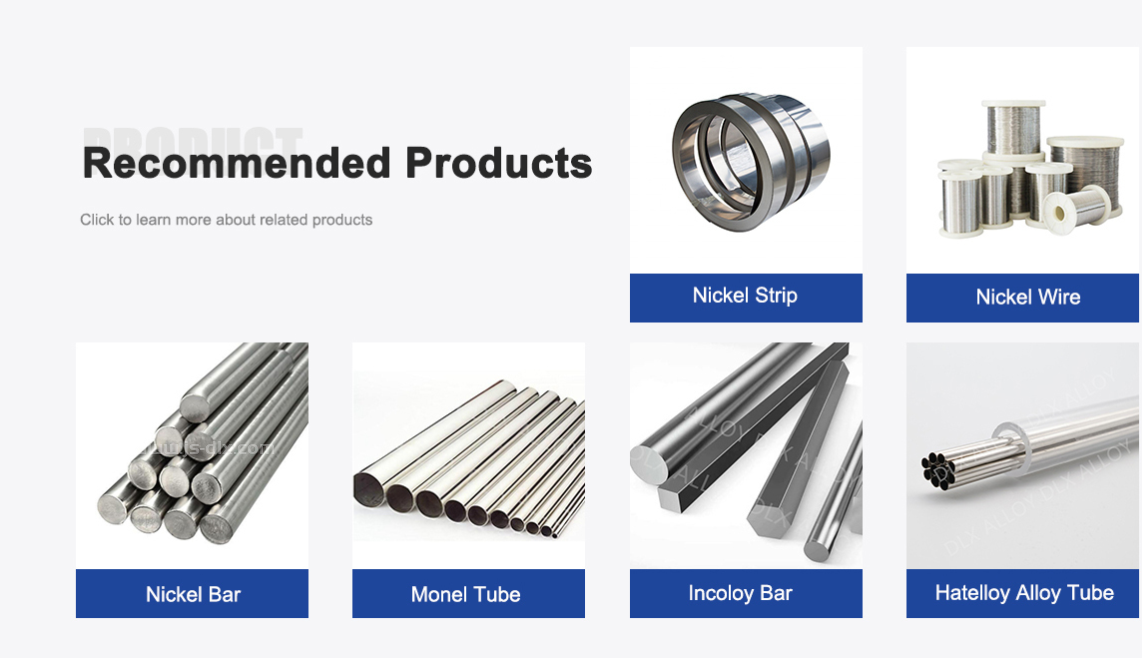

Recommended products

Company Profile

Our company Principle is " Quality first, Customer first".

CHANGZHOU DLX ALLOY CO, LTD was established in 2002 and has got Iso9001 International Quality Management System Certificate and SGS Certificate. Our factory is professional in researching and producing special alloy material. From melting, drawing, heat treatment, finishing and testing .We offer nickel-based, copper-based, and iron-based alloys, including super alloy, welding materials, anti-corrosion alloy, precision alloy, FeCrAl alloy, NiCr alloy, CuNi alloy, thermocouple and etc, in the form of wire, strip, ribbon, bar, tube, plate.

If any requirements and questions, please feel free to reach:

Sophie Wang | Sales +86 13275217619

International Sales Depart.

Jiangsu Victory Technology Co., Ltd

A: NO.32 West Taihu Road, Xinbei District, Changzhou, Jiangsu

FAQ

Oct.1-7 and Chinese New Year holiday . Pls email us during our holiday if u have any question.

Do you provide free samples?

Yes,we can provide a free sample for testing,buyer should bear all the shipping costs.

What is your payment terms?

T/T,L/C,D/A,D/P,Western Union,MoneyGram,Paypal

What is the lead time?

Usually sample lead time is 7 days after payment has been confirmed.