Product Description

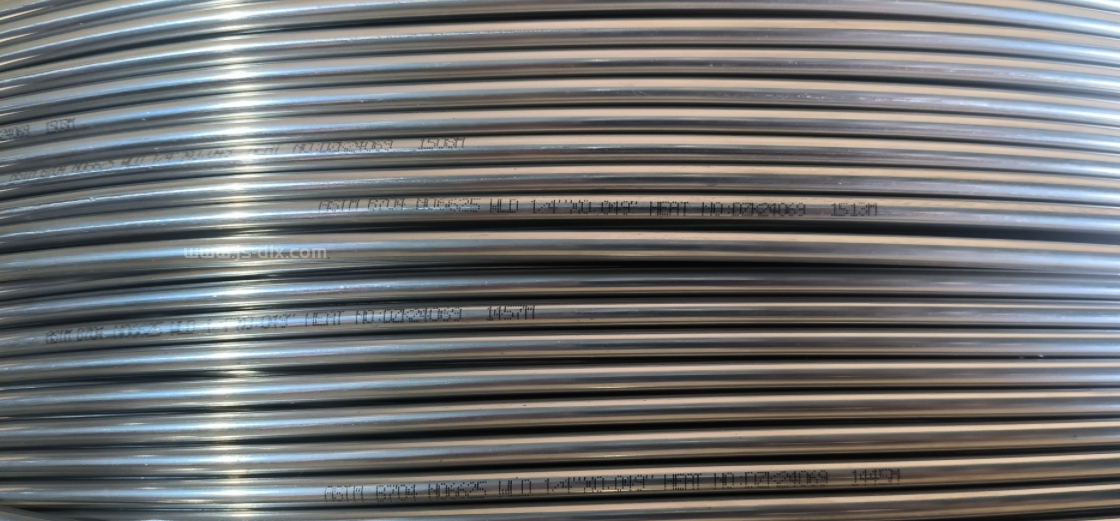

Inconel 625 coils stand out for their superior corrosion resistance, making them particularly effective in harsh conditions with exposure to aggressive chemicals. This nickel alloy retains its strength at elevated temperatures and shows remarkable durability, making it a preferred choice in aerospace and power generation applications. Its capacity to endure extreme environments guarantees that essential components function reliably and safely.

Differences between nickel-based welded pipes and coils

1. Form Factor

- Welded Pipes: Typically straight and cylindrical, designed for transporting fluids or gases.

- Coils: Curved or coiled forms, often used for heat exchange or flexible applications.

2. Manufacturing Process

- Welded Pipes: Made by welding together flat sheets of nickel-based alloys into a tube shape.

- Coils: Produced by bending and shaping nickel-based materials into a coil, allowing for easier installation in tight spaces.

3. Applications

- Welded Pipes: Commonly used in oil and gas, chemical processing, and construction for transporting fluids.

- Coils: Typically utilized in heat exchangers, refrigeration systems, and applications where flexibility is required.

4. Mechanical Properties

- Welded Pipes: Generally exhibit high strength and rigidity, suitable for high-pressure applications.

- Coils: May provide more flexibility and lower weight, making them easier to handle in certain installations.

5. Heat Resistance

- Welded Pipes: Often designed to withstand extreme temperatures and pressures, making them reliable for demanding environments.

- Coils: While also heat-resistant, their primary use is in applications needing efficient heat transfer.

6. Corrosion Resistance

- Welded Pipes: Offer excellent corrosion resistance, especially in harsh environments, due to the properties of nickel-based alloys.

- Coils: Similarly provide good corrosion resistance, but may have different performance characteristics based on their design and application.

7. Installation Requirements

- Welded Pipes: Usually require more rigid support and precise alignment during installation.

- Coils: More versatile in installation, as they can be easily bent and fitted into tight spaces.

8. Cost Factors

- Welded Pipes: May be more expensive due to the manufacturing process and materials used.

- Coils: Cost can vary based on the specific application and length needed, but they may be less expensive in flexible applications.

9. **Maintenance Needs**

- **Welded Pipes:** Often require periodic inspection for weld integrity and general wear.

- **Coils:** Maintenance may focus more on the efficiency of heat transfer and potential buildup of deposits.

10. End Connections

- Welded Pipes: Typically have standard flanged or threaded connections for easy integration into systems.

- Coils: May utilize fittings or connectors designed for flexibility and ease of assembly.

11. Weight

- Welded Pipes: Generally heavier due to their solid construction and thickness.

- Coils: Lighter and easier to transport, making them suitable for applications where weight is a concern.

12. Customization Options

- Welded Pipes: Custom lengths and diameters can be produced but may be limited by the welding process.

- Coils: Highly customizable in terms of diameter and coil length, allowing for tailored solutions in specific applications.

These points highlight the fundamental differences between nickel-based welded pipes and coils.

Detailed Information

To measure the strength and durability of Inconel 625 coils, we utilize water pressure testing. This process involves filling the coils with water and carefully increasing the pressure to assess their resistance to extreme conditions without leaks. The process includes:

Coil Inspection: Each coil is thoroughly examined and cleaned to remove any contaminants.

Sealing: Both ends of the coils are securely sealed to prevent any water loss during the testing phase.

Filling with Water: The coils are filled, ensuring removal of all air for accurate pressure readings.

Pressure Application: Pressure is raised gradually to the specified test level, often exceeding normal operating conditions for a rigorous assessment.

Monitoring: Throughout the test, pressure is carefully observed, and any leaks or deformations are documented.

Final Examination: After testing, the coils are scrutinized for any potential weaknesses to confirm they meet safety standards.

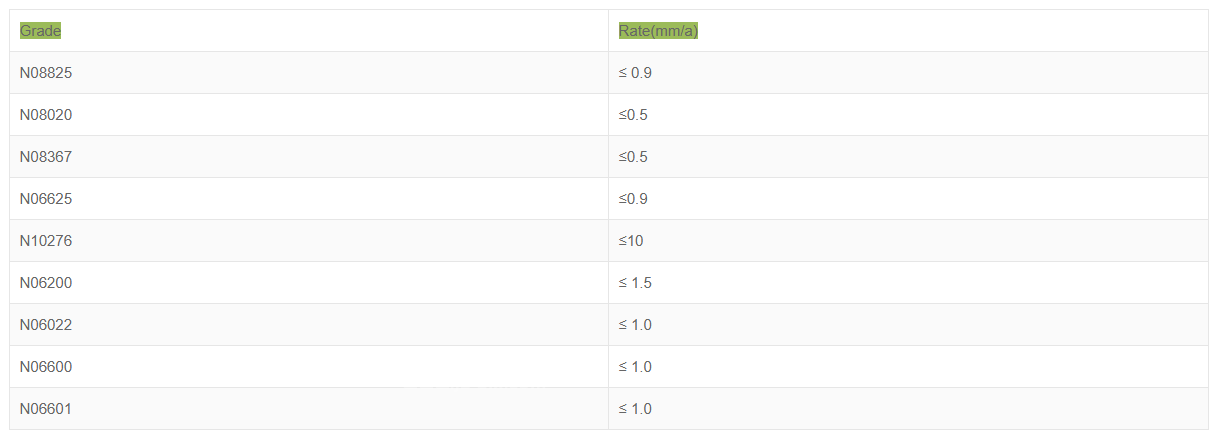

Corrosion Resistance Of Different Materials(G28 A Methord)

DLX ALLOY has advanced equipment, proven techniques, and professional teams. We strictly implement the Quality Management System and API Requirements to ensure that the quality meets the needs of the site. The tests like, NDT | X-ray | Tension test | Hydrostatic test

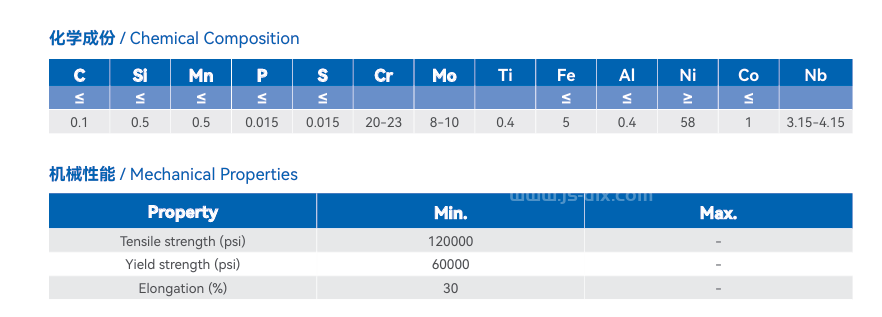

Product Parameters

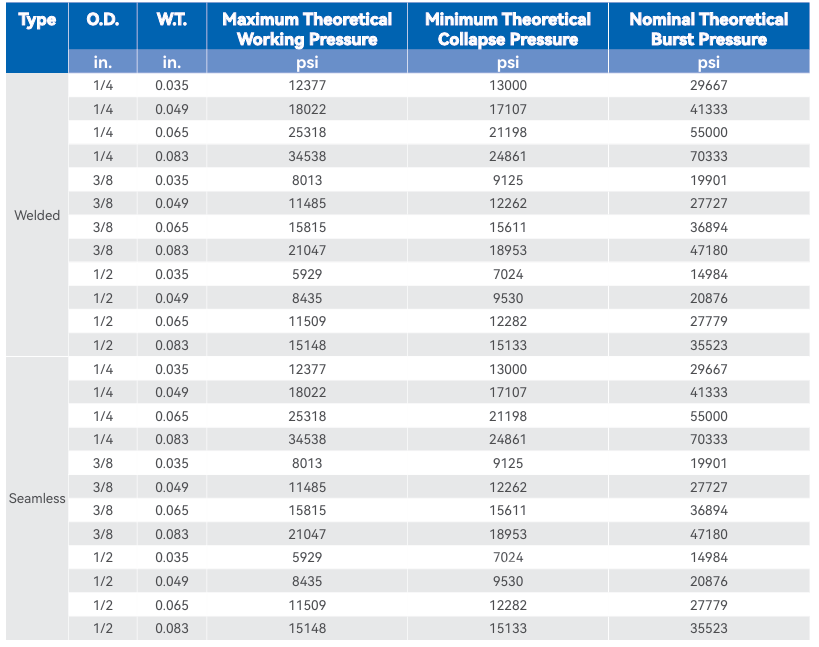

Size Dependant Characteristics (Based Upon Nominal Tubing Dimensions)

Recommended products

Company Profile

Our company Principle is " Quality first, Customer first".

CHANGZHOU DLX ALLOY CO, LTD was established in 2002 and has got Iso9001 International Quality Management System Certificate and SGS Certificate. Our factory is professional in researching and producing special alloy material. From melting, drawing, heat treatment, finishing and testing .We offer nickel-based, copper-based, and iron-based alloys, including super alloy, welding materials, anti-corrosion alloy, precision alloy, FeCrAl alloy, NiCr alloy, CuNi alloy, thermocouple and etc, in the form of wire, strip, ribbon, bar, tube, plate.

If any requirements and questions, please feel free to reach:

Sophie Wang | Sales +86 13275217619

International Sales Depart.

Jiangsu Victory Technology Co., Ltd

A: NO.32 West Taihu Road, Xinbei District, Changzhou, Jiangsu

FAQ

Oct.1-7 and Chinese New Year holiday . Pls email us during our holiday if u have any question.

Do you provide free samples?

Yes,we can provide a free sample for testing,buyer should bear all the shipping costs.

What is your payment terms?

T/T,L/C,D/A,D/P,Western Union,MoneyGram,Paypal

What is the lead time?

Usually sample lead time is 7 days after payment has been confirmed.