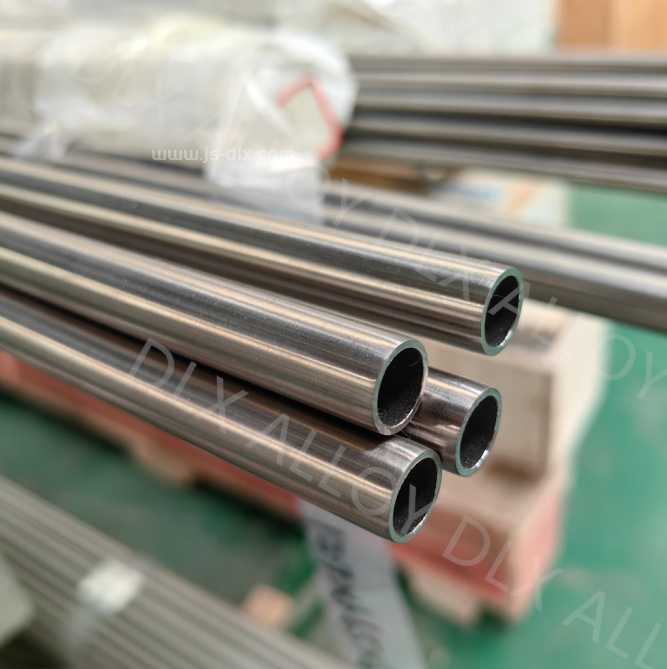

Product Description:

Inconel 690 is a high-performance nickel-chromium alloy designed for exceptional strength and resistance to oxidation and corrosion, particularly in high-temperature environments. It is ideal for applications that require superior durability and reliability under extreme conditions.

Applications:Inconel 690 tubes are extensively used in power generation, nuclear reactors, and petrochemical industries. They are commonly found in heat exchangers, superheaters, and other components that must endure intense thermal and corrosive environments.

Advantages:

High-Temperature Strength: Maintains mechanical properties at elevated temperatures, ensuring performance and longevity.

Corrosion Resistance: Offers excellent resistance to oxidation and carburization, making it suitable for harsh environments.

Durability: With a minimum nickel content of 58% and a density of 8.19 g/cm³, Inconel 690 provides long-lasting reliability and structural integrity.

Versatility: The alloy is easily weldable and formable, accommodating various industrial fabrication requirements.

Company Profile:DLX Alloy is a company dedicated to the production and research and development of alloys. Founded in 2002, we initially focused on the production of resistance alloys. Over the past 20 years, we have continued to conduct research and development and now offer a range of alloy products, including Inconel, Monel, Hastelloy, high-temperature alloys, and other nickel-based alloys. Our commitment to meeting the needs of industries that require high strength, strong corrosion resistance, and high-temperature performance is reflected in our focus on developing these alloys.

Inconel 690 Tube - FAQ

1. What is Inconel 690 used for?

Inconel 690 tubes are used in power generation, nuclear reactors, and petrochemical industries, where high temperature and corrosion resistance are required.

2. What are the key properties of Inconel 690?

Inconel 690 features high tensile strength, excellent oxidation resistance, a minimum nickel content of 58%, and a density of 8.19 g/cm³.

3. Can Inconel 690 withstand high temperatures?

Yes, Inconel 690 is designed to perform well in extreme temperatures while maintaining its strength and resistance to corrosion.

4. Is Inconel 690 weldable?

Yes, Inconel 690 has good weldability, making it suitable for various industrial applications.

5. What industries commonly use Inconel 690 tubes?

Inconel 690 tubes are commonly used in power generation, nuclear reactors, and the petrochemical industry.