Product Description

Inconel 625 coils are highly regarded for their exceptional corrosion resistance, making them suitable for challenging environments with harsh chemicals. This nickel alloy maintains its strength even at elevated temperatures and offers remarkable durability, positioning it as a favored choice for essential applications in aerospace and energy sectors. Its ability to endure extreme conditions ensures that components remain reliable, which is crucial for maintaining safety and efficiency in operations.

Applications

Here are the various sectors where Inconel 625 coils are effectively utilized:

- Aerospace: Essential for components like engines and exhaust systems due to their strength at high temperatures and resistance to oxidation.

- Chemical Industry: Ideal for equipment such as reactors and heat exchangers, providing superb protection against aggressive chemicals.

- Marine Applications: Employed in offshore platforms and subsea technology, designed to withstand the harsh conditions of seawater.

- Energy Production: Integral to gas turbines and nuclear reactors, where enduring high temperatures and pressures is critical.

- Oil and Gas: Used in drilling tools and valves, specifically engineered to resist sour gas and various corrosive substances.

- Automotive Sector: Common in high-performance exhaust systems, built to handle intense temperatures and corrosive environments.

- Manufacturing: Applied in processes that involve extreme heat and corrosive materials, ensuring consistent durability and performance.

Detailed Information

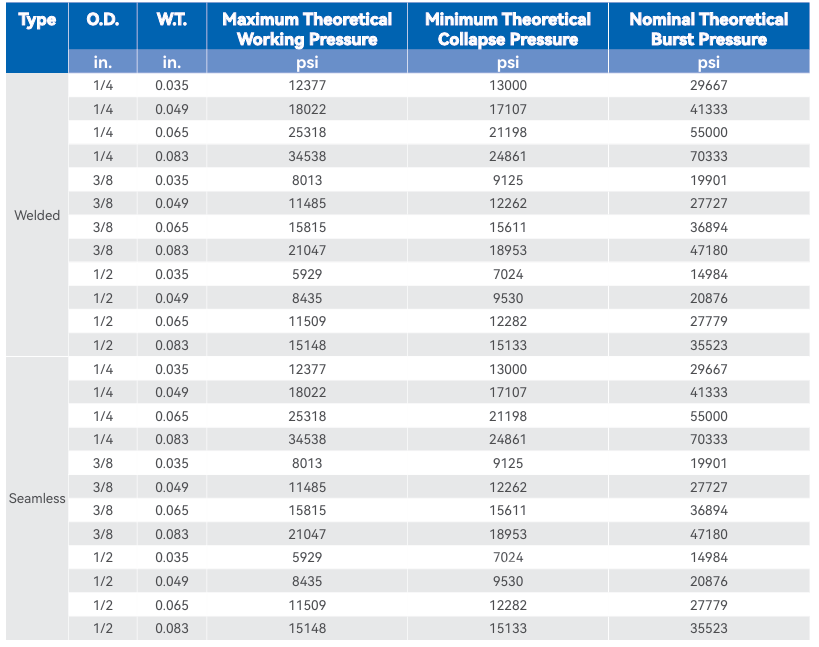

To evaluate the strength and durability of Inconel 625 coils, we conduct a water pressure test.

This method involves filling the coils with water and systematically increasing the pressure to determine their ability to withstand extreme conditions without leaks or failures.

The process consists of the following key steps:

1. Preparation: Coils are meticulously inspected and cleaned to remove any defects or contaminants that could affect the test results.

2. Sealing: Both ends of the coils are tightly sealed to ensure no water escapes during the testing phase.

3. Filling: The coils are filled with water, ensuring all air is purged to achieve accurate pressure readings.

4. Pressure Application: Pressure is gradually increased to the specified test level, often exceeding normal operating pressures, to assess the coils' structural integrity.

5. Monitoring: Throughout the test, pressure levels are continuously tracked, and any signs of leaks or deformation are recorded.

6. Evaluation: After testing, the coils are thoroughly examined for any damage or weaknesses to verify they meet required safety and performance criteria.

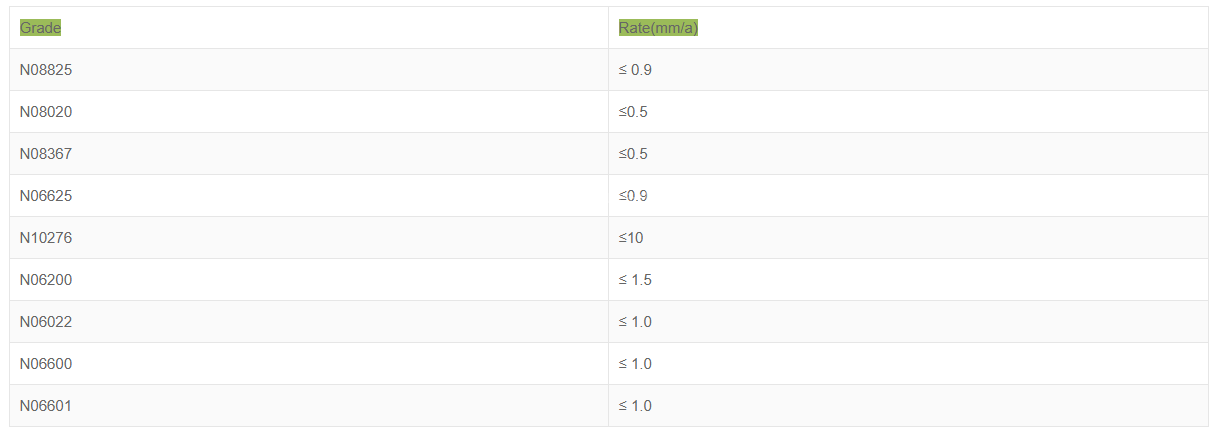

Corrosion Resistance Of Different Materials(G28 A Methord)

DLX ALLOY has advanced equipment, proven techniques, and professional teams. We strictly implement the Quality Management System and API Requirements to ensure that the quality meets the needs of the site. The tests like, NDT | X-ray | Tension test | Hydrostatic test

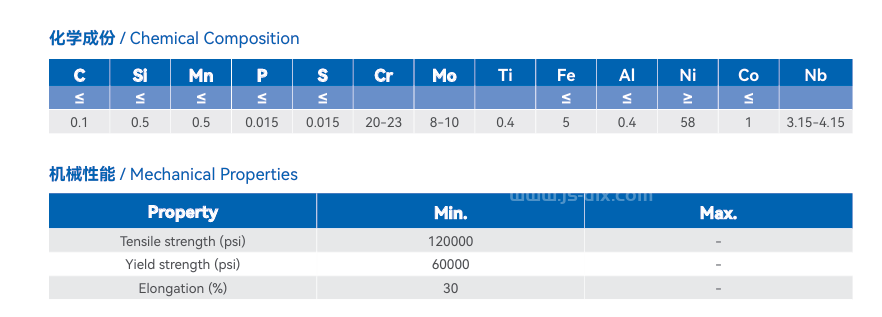

Product Parameters

Recommended products

Company Profile

Our company Principle is " Quality first, Customer first".

CHANGZHOU DLX ALLOY CO, LTD was established in 2002 and has got Iso9001 International Quality Management System Certificate and SGS Certificate. Our factory is professional in researching and producing special alloy material. From melting, drawing, heat treatment, finishing and testing .We offer nickel-based, copper-based, and iron-based alloys, including super alloy, welding materials, anti-corrosion alloy, precision alloy, FeCrAl alloy, NiCr alloy, CuNi alloy, thermocouple and etc, in the form of wire, strip, ribbon, bar, tube, plate.

If any requirements and questions, please feel free to reach:

Sophie Wang | Sales +86 13275217619

International Sales Depart.

Jiangsu Victory Technology Co., Ltd

A: NO.32 West Taihu Road, Xinbei District, Changzhou, Jiangsu

FAQ

Oct.1-7 and Chinese New Year holiday . Pls email us during our holiday if u have any question.

Do you provide free samples?

Yes,we can provide a free sample for testing,buyer should bear all the shipping costs.

What is your payment terms?

T/T,L/C,D/A,D/P,Western Union,MoneyGram,Paypal

What is the lead time?

Usually sample lead time is 7 days after payment has been confirmed