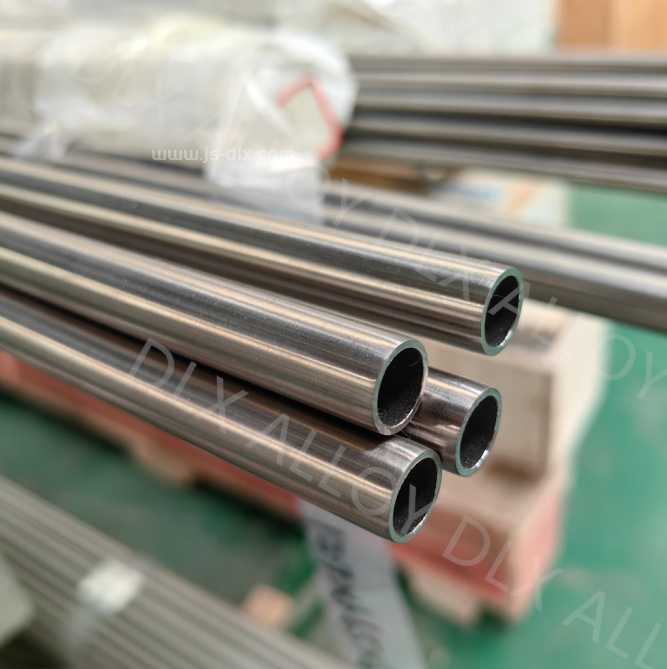

Product Description:

Inconel 718 is a high-performance nickel-chromium alloy known for its exceptional strength and resistance to high temperatures, oxidation, and corrosion. This alloy is ideal for demanding applications that require both durability and reliability in extreme environments.

Applications:Inconel 718 tubes are widely used in aerospace, oil and gas, power generation, and chemical processing industries. They are employed in critical components such as gas turbine engines, downhole tools, reactor cores, and heat exchangers, where high strength and resistance to harsh conditions are essential.

Advantages:

High-Temperature Strength: Inconel 718 maintains its mechanical properties at elevated temperatures, making it suitable for high-stress applications.

Corrosion Resistance: Provides excellent resistance to oxidation, carburization, and various corrosive environments, ensuring long-term performance.

Versatility: The alloy offers good weldability and formability, allowing for the production of complex shapes and components.

Fatigue Resistance: Exhibits outstanding resistance to fatigue and stress, enhancing the durability of components under cyclic loading conditions.

Product Process:

Company Profile:

DLX Alloy is a company dedicated to the production and research and development of alloys. Founded in 2002, we initially focused on the production of resistance alloys. Over the past 20 years, we have continued to conduct research and development and now offer a range of alloy products, including Inconel, Monel, Hastelloy, high-temperature alloys, and other nickel-based alloys. Our commitment to meeting the needs of industries that require high strength, strong corrosion resistance, and high-temperature performance is reflected in our focus on developing these alloys.