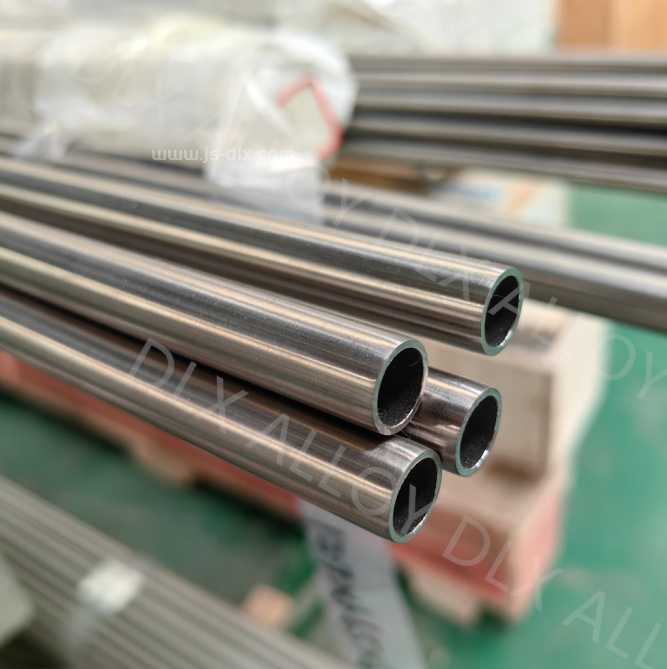

Product Description:

Inconel X-750 is a high-performance nickel-chromium alloy designed to excel in extreme environments. Known for its exceptional strength and resistance to high temperatures and oxidation, Inconel X-750 is ideal for demanding industrial applications where reliability and durability are critical.

Applications:Inconel X-750 tubes are extensively used in aerospace, gas turbines, and power generation. They are ideal for components such as turbine blades, seals, and high-stress engine parts that require robust performance in high-temperature and corrosive environments.

Advantages:

High-Temperature Strength: Maintains superior mechanical properties at elevated temperatures, ensuring reliable performance in extreme conditions.

Corrosion and Oxidation Resistance: Offers excellent protection against oxidation and corrosive environments, extending the lifespan of critical components.

Versatile Usage: Suitable for high-stress applications in aerospace and industrial sectors, with good weldability and formability.

Durability: With a high nickel content (minimum 70%) and a density of 8.30 g/cm³, Inconel X-750 delivers exceptional strength and resistance to fatigue.

Choose Inconel X-750 tubes for unmatched performance and durability in your most demanding applications. Experience the benefits of advanced alloy technology with proven reliability in high-temperature environments.

Product Process:

Product Profile:

DLX Alloy is a company dedicated to the production and research and development of alloys. Founded in 2002, we initially focused on the production of resistance alloys. Over the past 20 years, we have continued to conduct research and development and now offer a range of alloy products, including Inconel, Monel, Hastelloy, high-temperature alloys, and other nickel-based alloys. Our commitment to meeting the needs of industries that require high strength, strong corrosion resistance, and high-temperature performance is reflected in our focus on developing these alloys.

FAQ: Inconel X-750 Tubing

Q1: What is Inconel X-750?

A1: Inconel X-750 is a nickel-chromium-based superalloy designed for high-temperature applications, offering excellent oxidation and corrosion resistance.

Q2: What are the key properties of Inconel X-750 tubing?

A2: The tubing has high tensile strength, good oxidation resistance, and excellent stress-corrosion cracking resistance. It performs well at temperatures up to 1800°F (982°C).

Q3: What applications are suitable for Inconel X-750 tubing?

A3: It is commonly used in aerospace, power generation, and chemical processing industries, especially in environments involving high temperatures and corrosive conditions.

Q4: What are the typical dimensions available for Inconel X-750 tubing?

A4: Tubing is available in various diameters and wall thicknesses. Custom sizes can be ordered based on specific requirements.

Q5: How should Inconel X-750 tubing be handled and stored?

A5: Handle with care to avoid mechanical damage. Store in a clean, dry environment to prevent contamination and oxidation.

Q6: Can Inconel X-750 tubing be welded?

A6: Yes, it can be welded using appropriate techniques and filler materials suitable for Inconel Alloys.

Q7: How does Inconel X-750 compare to other alloys like Inconel 718?

A7: Inconel X-750 has similar high-temperature properties to Inconel 718 but is generally more resistant to stress-corrosion cracking.