Welcome to Changzhou DLX Alloy Co., Ltd.

Email:sales8@dlx-alloy.com Mobile/Whatsapp:+86 199 0611 9641

Specialized manufacturer of heaters, thermocouples and titanium,over 20 years.

Welcome to Changzhou DLX Alloy Co., Ltd.

Email:sales8@dlx-alloy.com Mobile/Whatsapp:+86 199 0611 9641

Specialized manufacturer of heaters, thermocouples and titanium,over 20 years.

Whatsapp:+86 199 0611 9641

Email:sales8@dlx-alloy.com

Add:NO.32 West Taihu Road, Xinbei District, Changzhou, Jiangsu,China

Inconel Pipe

Product Details

Alloy Products Alloy Steel Product Inconel 600 601 617 625 690 718 Pipe for Aerospace and Cryogenic

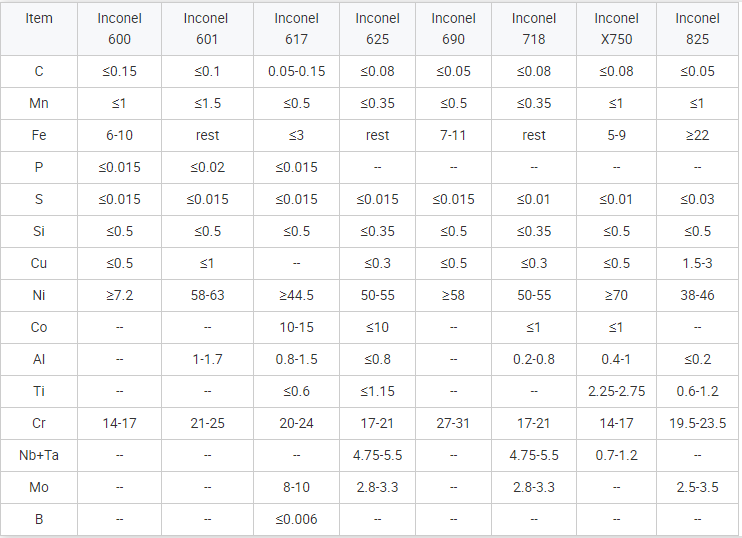

Inconel 600 Inconel 600 is a common nickel-chromium alloy known for its excellent resistance to high temperatures and corrosion as well as good mechanical properties. It is commonly used in application scenarios requiring high strength and corrosion resistance. ‘Nickel (Ni): approx. 72 per cent

Chromium (Cr): 14-17 per cent

Iron (Fe): 8-10%’ ’HIGH TEMPERATURE RESISTANCE: Maintains good strength and stability at temperatures up to 1,100°C (about 2,000°F).

CORROSION RESISTANCE: Good resistance to a wide range of chemical media including oxidising acids, alkalis and chlorides.

STRENGTH AND HARDNESS: Maintains good mechanical properties at elevated temperatures, including strength and toughness.

Machinability: Easily machined and welded, and can be used to manufacture complex components.’

Inconel 601 Inconel 601 is a nickel-chromium alloy specifically designed to provide excellent corrosion and heat resistance in high-temperature environments. It is based on an improved version of Inconel 600 with enhanced oxidation resistance and higher heat resistance ‘Nickel (Ni): approx. 58 per cent

Chromium (Cr): 21-25 per cent

Iron (Fe): about 17%

Small amounts of aluminium (Al) and molybdenum (Mo)’ ’High Temperature Resistance: Stable operation at temperatures up to 1200°C (approx. 2200°F), providing excellent high temperature strength.

CORROSION RESISTANCE: Provides excellent corrosion resistance to oxidising media, sulphides, chlorides, etc.

Oxidation Resistance: Due to the addition of aluminium, Inconel 601 performs well in high temperature oxidation environments, forming a stable oxide film to protect the substrate.

Mechanical Properties: Maintains good mechanical strength and toughness at high temperatures.’

Inconel 617 Inconel 617 is a nickel-chromium alloy known for its excellent high-temperature strength and oxidation resistance. It is primarily used in extreme high temperature environments, especially in applications requiring good oxidation and corrosion resistance. ‘Nickel (Ni): approx. 50 per cent

Chromium (Cr): 20-24 per cent

Molybdenum (Mo): 9-12 per cent

Aluminium (Al): 0.9 - 1.7%

Iron (Fe): remainder’ ’High Temperature Resistance: Capable of operating at temperatures up to 1150°C (approx. 2100°F), providing excellent high temperature strength and stability.

OXIDATION RESISTANCE: Due to the addition of aluminium, Inconel 617 performs well in high-temperature oxidation environments, forming a stable oxide film to protect the substrate.

Corrosion Resistance: Good resistance to a variety of corrosive media (e.g. chlorides, sulphides, etc.).

Strength and toughness: maintain high strength and good toughness at high temperatures, suitable for high-stress environments.

Inconel 625 Inconel 625 is a high-strength, corrosion-resistant nickel-chromium-molybdenum alloy used in a wide range of extreme environments for its excellent properties. It has excellent resistance to heat, oxidation and corrosion and is particularly suitable for use in harsh chemical and thermal conditions. ‘Nickel (Ni): 58% (min)

Chromium (Cr): 20-23 per cent

Molybdenum (Mo): 8-10 per cent

Iron (Fe): remainder

Trace amounts of aluminium (Al), titanium (Ti) and other elements’ ’High Temperature Resistance: Maintains good strength and stability at temperatures up to 980°C (approx. 1800°F).

CORROSION RESISTANCE: Excellent resistance to corrosion in seawater, acidic and alkaline environments.

OXIDATION RESISTANCE: Excellent resistance to oxidising media.

Strength and toughness: at high temperatures to maintain high strength and good toughness.

Inconel 690 Inconel 690 is a high-temperature corrosion-resistant nickel-chromium alloy with excellent high-temperature strength and corrosion resistance. It is primarily used in extreme environments, especially in applications requiring high temperature performance and long term stability. ‘Nickel (Ni): 58-63 per cent

Chromium (Cr): 28-31 per cent

Iron (Fe): 5-8 per cent

Trace amounts of molybdenum (Mo), titanium (Ti), and aluminium (Al)’ ’HIGH TEMPERATURE RESISTANCE: Capable of operating at temperatures up to 1,050°C (approximately 1,920°F) with excellent high temperature strength and stability.

CORROSION RESISTANCE: Provides excellent corrosion resistance, especially to corrosive media such as oxidation, sulfides and chlorides.

Oxidation Resistance: Due to its high chromium content, Inconel 690 performs well in high-temperature oxidising environments, forming a stable oxide film to protect the substrate at high temperatures.

Stress corrosion cracking resistance: good resistance to stress corrosion cracking.

Inconel 718 Inconel 718 is a widely used nickel-chromium alloy specifically designed for use in high-temperature and high-stress environments. It is favoured for its excellent high temperature strength, corrosion resistance and good machinability for a wide range of aerospace and energy applications. ‘Nickel (Ni): 50-55 per cent

Chromium (Cr): 17-21 per cent

Molybdenum (Mo): 2.8-3.3 per cent

Tungsten (W): 1.0-1.5 per cent

Niobium (Nb): 4.75-5.5 per cent

Titanium (Ti): 0.65-1.15 per cent

Trace amounts of aluminium (Al) and other elements

The balance is mainly iron (Fe)’ ’High Temperature Resistance: Can work at temperatures up to 700°C (about 1300°F), providing excellent high temperature strength and stability.

CORROSION RESISTANCE: Provides good resistance to most chemical media and chlorides.

STRENGTH AND TOUGHNESS: Maintains high strength at elevated temperatures and has good fatigue strength and toughness.

Machinability: Despite its high hardness, it can be machined and welded, making it suitable for the fabrication of complex structures.

The Inconel Alloy has a specific heat of 444 J/kg-°C, which is a measure of its ability to store heat. This property makes it an excellent choice for applications that require a material with high thermal conductivity. Additionally, its melting range of 1332-1380 ℃ makes it a perfect choice for high-temperature applications.

The Inconel Alloy is a type of nickel pipe that is widely used in the manufacturing of various industrial products. Its specific heat capacity of 0.431 J/g-°C makes it an excellent choice for heat exchanger applications where thermal conductivity is critical.

The Inconel Alloy is mainly used in high-temperature applications such as gas turbine blades, heat exchangers, and furnace hardware. Its exceptional resistance to oxidation and corrosion makes it an ideal choice for harsh environments such as chemical processing plants and oil rigs.

Inconel Alloy is also a popular choice for Inconel 625 cladding, which refers to the process of bonding two or more metals together to create a composite material. Inconel 625 cladding is widely used in the manufacturing of chemical processing equipment, offshore oil rigs, and power generation facilities.

Overall, the Inconel Alloy is a versatile and reliable alloy steel metal that offers exceptional resistance to high temperatures, corrosion, and oxidation. Its unique properties make it an ideal choice for various industrial applications, including heat exchangers, gas turbine blades, and furnace hardware.

One common application of the DLX Inconel Alloy is in the oil and gas industry, where it is used for Inconel 625 cladding. This technique involves applying a layer of Inconel 625 over a base metal to improve its corrosion resistance and extend its service life. The Inconel Alloy can also be used in the aerospace industry to produce high-performance parts and equipment that can withstand extreme conditions. Its low temperature resistance down to -253°C makes it a popular choice for cryogenic applications.

The DLX Inconel Alloy is also widely used as an alloy steel product in the chemical and petrochemical industries. Its resistance to corrosion and high temperatures makes it suitable for various applications such as heat exchangers, reactors, and piping systems. The surface finish of solid solution + acid white provides an attractive appearance that is highly valued in the chemical industry. Additionally, the specific heat of 444 J/kg-°C allows the Inconel Alloy to absorb and release heat efficiently, which makes it a popular choice in high-temperature applications.

In conclusion, the DLX Inconel Alloy is a versatile and durable product that can be applied in various industries and scenarios. Its outstanding properties such as low temperature resistance, high tensile strength, and excellent corrosion resistance make it a reliable and popular choice for applications such as Inconel 625 cladding, alloy steel products, and high-performance parts and equipment.

DLX offers product customization services for our Inconel Alloy, a high-strength alloy steel metal. Our Inconel Alloy, also known as Incoloy Alloy 20 Plate Sheet, has a yield strength of 310 MPa and meets ASTM and ASME standards. It is made in China and has a brand number of Alloys 625 NS3306 NO6625 2.4856.

Our product customization services allow you to tailor the Inconel Alloy to your specific needs, whether it be size, shape, or surface finish. Our Inconel Alloy has a solid solution + acid white surface finish, but we also offer customization options for CuNi Alloy and other alloy steel products.

Our Inconel Alloy product comes with comprehensive technical support and services to ensure optimal performance and reliability. Our team of experts is available to assist with any product-related queries, including installation, maintenance, and troubleshooting. We also offer training programs to help customers maximize the benefits of our product. In addition, we provide customization services to meet specific customer requirements. Our goal is to ensure that our customers have a seamless experience with our Inconel Alloy product and achieve their desired outcomes.

The Inconel Alloy product will be securely packaged in a wooden crate or a cardboard box, depending on the size and quantity of the product.

The product will be wrapped with protective material to prevent any damage during transportation.

All necessary labels and markings will be clearly displayed on the packaging.

The Inconel Alloy product will be shipped via a reputable courier service.

The shipping cost will be calculated based on the weight and destination of the product.

The estimated delivery time will be provided to the customer once the shipment is processed.

The customer will be provided with a tracking number to track the shipment and receive updates on the delivery status.

CHANGZHOU DLX ALLOY CO, LTD was established in 2002 and has got Iso9001 International Quality Management System Certificate and SGS Certificate. Our factory is professional in researching and producing special alloy material. From melting, drawing, heat treatment, finishing and testing .We offer nickel-based, copper-based, and iron-based alloys, including super alloy, welding materials, anti-corrosion alloy, precision alloy, FeCrAl alloy, NiCr alloy, CuNi alloy, thermocouple and etc, in the form of wire, strip, ribbon, bar, tube, plate.

Q: What is the brand name of this product?

A: The brand name of this product is DLX.

Q: What is the model number of this product?

A: The model number of this product is Inconel Alloy.

Q: Where is this product manufactured?

A: This product is manufactured in China.

Q: What are the key features of this product?

A: Inconel Alloy is a high-performance nickel-chromium alloy that offers excellent resistance to corrosion and high temperatures.

Q: What applications is this product typically used for?

A: Inconel Alloy is commonly used in applications that require high strength and resistance to extreme temperatures, such as in gas turbines, aerospace components, and chemical processing equipment.