Product Description

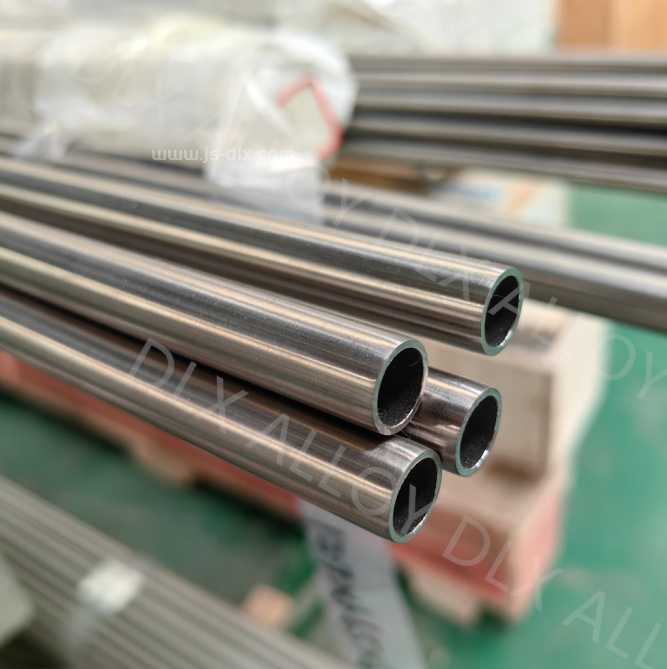

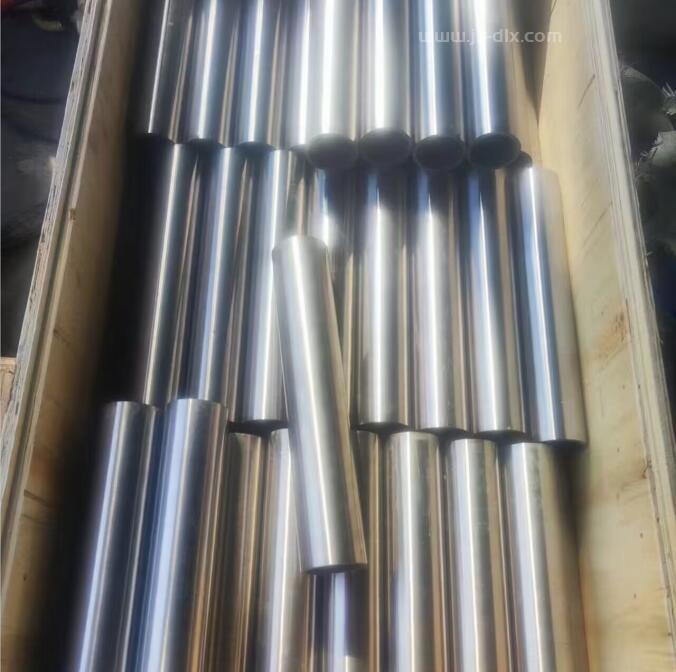

Inconel X750 tubes are hollow cylindrical forms made from Inconel X750 alloy, a high-performance nickel-chromium-based superalloy. These tubes leverage the alloy's exceptional properties to serve various demanding applications. Here are some key details about Inconel X750 tubes:

Production: Inconel X750 tubes are produced through processes like extrusion or seamless tube manufacturing, where the alloy is formed into hollow cylinders.

Sizes and Specifications: The tubes come in various diameters, wall thicknesses, and lengths to meet specific application requirements. They can be customized based on the needs of the industry or application.

Inconel X750 Tube is a kind of nickel-chromium alloys. Alloy X750 offers superior resistance to oxidation, corrosion, and scaling at elevated temperatures, which makes it ideal for use in these demanding conditions. It maintains its strength and stability even under thermal cycling, where materials are repeatedly heated and cooled. This ensures that fixtures made from Inconel X750 remain dimensionally stable and resistant to warping or degradation over time, leading to consistent, high-quality results in heat treatment processes. Furthermore, the wire form of Inconel X750 allows for the creation of complex fixture designs, providing flexibility for various industrial applications.

Chemical Component

| Model No. | Inconel X750 |

| Type | Nickel Alloy Tube |

| Density | 8.47 |

| Elongation | 2~5 |

| Technology | Cold Drawing |

| Melting Range | 1354-1413c |

| Tensile Strength | 1170-1520MPa |

| Yield Strength | 1035-1450MPa |

| Surface | Bright/Acid White/Oxidation |

| Transport Package | Carton or Wooden Box |

Physical Properties

Density: 0.299 lb/in3, (8.28 g/cm3)

Modulus of Elasticity (E):

At 70°F (20°C): 31.0 x 106 psi (214 GPa)

At 1000°F (538°C): 26.7 x 106 psi (184 GPa)

Modulus of Rigidity (G):

At 70°F (20°C): 12.0 x 106 psi (82.7 GPa)

Coefficient of Expansion:

7.8 µin/in.-°F (70°F to 1000°F)

14.5 µm/m-°C (20°C to 538°C)

Electrical Resistivity: 20.1 µΩ.in, (122 µΩ.cm)

Thermal Conductivity: 83 Btu-in/ft2hr-°F, (12.0 W/m-K)

Inconel X-750 Pipes & Tubes Specification

Specifications ASTM B163, B165 / ASME SB163, SB165

Dimensions ASTM, ASME and API

Size Range 15"NB – 150"NB

Outer Diameter 6.35 mm OD upto 254 mm OD in 0.6 TO 20 mm thickness.

Schedule SCH 10, SCH20, SCH30, SCH40, STD, SCH60, XS, SCH80, SCH120, SCH140, SCH160, XXS

Type Seamless / ERW / Welded / Fabricated / LSAW Pipes

Length Single Random, Double Random & Cut Length

Form Round Pipes/Tubes, Square Pipes/Tubes, Rectangular Pipe/Tubes, Coiled Tubes, "U" Shape, Pan Cake Coils, Hydraulic Tube

Grade X-750 UNS (N07750), DIN (2.4669)

Packaging&Shipping

Company Profile

About CHANGZHOU DLX ALLOY CO., LTD

Founded in 2002, CHANGZHOU DLX ALLOY CO., LTD is a leading manufacturer specializing in the research and production of specialized alloy materials. Our factory has earned both the ISO9001 International Quality Management System Certificate and SGS Certification, affirming our commitment to high standards of quality.

We are experts in the entire alloy production process, including melting, drawing, heat treatment, finishing, and rigorous testing. Our product range includes nickel-based, copper-based, and iron-based alloys, such as super alloys, welding materials, anti-corrosion alloys, precision alloys, FeCrAl alloys, NiCr alloys, CuNi alloys, and thermocouples. These are available in various forms including wire, strip, ribbon, bar, tube, and plate.