30% Elongation Inconel Pipe with Thermal Expansion of 13-17 µm/mK

Product Description:

One of the most significant advantages of using Inconel Alloy is its high Specific Heat. This property makes it an excellent choice for applications that require high-temperature resistance. The Specific Heat of Inconel Alloy is 444 J/kg-°C, which means that it can absorb and release heat quickly, making it ideal for use in heat exchangers.

Another key attribute of Inconel Alloy is its non-magnetic properties. This makes it an excellent choice for applications in which magnetic interference can be problematic. Inconel Alloy is also highly resistant to corrosion, making it ideal for use in harsh environments where other metals might fail.

Inconel Alloy has excellent Low Temperature Resistance, making it suitable for use in extremely cold environments. It can withstand temperatures down to -253°C, making it an ideal choice for applications in the aerospace industry, where aircraft need to operate in extremely low temperatures.

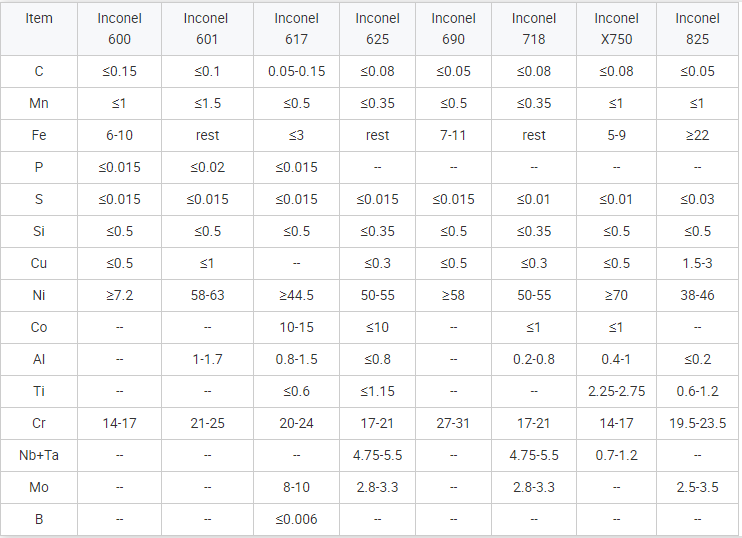

The Inconel Alloy family includes a variety of alloys, each with its unique set of properties. Inconel Alloys are known for their excellent strength and resistance to high-temperature environments. They are commonly used in a wide range of applications, including gas turbines, heat exchangers, and chemical processing equipment.

One of the most popular applications for Inconel Alloy is in heat exchangers. Inconel Alloy's high Specific Heat and excellent resistance to corrosion make it an ideal material for use in heat exchangers. Inconel Alloy can withstand high temperatures and pressure, making it perfect for use in environments where other metals might fail.

In conclusion, Inconel Alloy is one of the best Alloy Steel Metal products in the market. Its unique combination of properties makes it an ideal choice for a wide range of applications, including heat exchangers, gas turbines, and chemical processing equipment. With its high Specific Heat, non-magnetic properties, and excellent low-temperature resistance, Inconel Alloy is a reliable and durable choice for any project that requires a high-performance alloy steel product.

Applications:

The DLX Inconel Alloy is a highly versatile product that is commonly used in a wide range of applications, including the heat exchanger. This product is also known for its impressive yield strength of 310 MPa, which makes it an ideal choice for applications that require high strength and durability.

In addition to its low-temperature resistance and high yield strength, the DLX Inconel Alloy also boasts a specific heat capacity of 0.431 J/g-°C and an elongation rate of 30%. These features make the product highly desirable for use in a variety of settings where temperature control is critical.

Another notable feature of the DLX Inconel Alloy is its Inconel 625 cladding, which provides an extra layer of protection against corrosion and other forms of damage. This cladding makes the product ideal for use in harsh environments where corrosion and damage are likely to occur.

Overall, the DLX Inconel Alloy is a highly versatile product that can be used in a wide range of applications. Its high strength, low-temperature resistance, and excellent corrosion resistance make it an ideal choice for use in the heat exchanger and other alloy products.

Customization:

At DLX, we offer product customization services for our Inconel Alloy products which are made from high-quality Alloy Steel Metal. Our Inconel Alloys are available in different grades including Alloys 625 NS3306 NO6625 2.4856. They are manufactured in China, ensuring their high quality and durability. Our Inconel Alloy products have a specific heat of 444 J/kg-°C and a specific heat capacity of 0.431 J/g-°C. They are also non-magnetic, making them ideal for various applications. We also offer customizations for CuNi Alloy Products to meet your specific needs. Contact us now for more information on our product customization services.

Support and Services:

Our technical support team is available to assist with any questions or concerns regarding the use and application of our Inconel Alloy products. We offer a range of services to ensure the optimal performance and longevity of our products, including:

Product selection and specification guidance

Material testing and analysis

Customized product development

On-site installation and maintenance support

Product performance evaluations and recommendations

Training and education on Inconel Alloy products

Our team of experts is committed to providing the highest level of technical support and services to our valued customers.

Packing and Shipping:

Product Name: Inconel Alloy

Product Description: Inconel is a family of austenitic nickel-chromium-based superalloys.

Packaging: The product will be packed in a sturdy wooden box to ensure safe transportation. Each box will contain 25 kg of Inconel Alloy.

Shipping: The product will be shipped through a reliable courier service to ensure timely delivery and safe handling. The shipping charges will be calculated based on the delivery location and weight of the package.

FAQ:

Q: What is the brand name of this product?

A: The brand name of this product is DLX.

Q: What is the model number of this product?

A: The model number of this product is Inconel Alloy.

Q: Where is this product made?

A: This product is made in China.

Q: What are the main features of this product?

A: Inconel Alloy is a high-performance material with excellent corrosion resistance, high temperature resistance, and good mechanical properties.

Q: What applications is Inconel Alloy suitable for?

A: Inconel Alloy is suitable for a wide range of applications, including aerospace, chemical processing, nuclear power, and marine engineering.