Inconel X750 is a nickel-chromium-iron alloy that is known for its exceptional high-temperature strength and oxidation resistance. It is designed to withstand extreme conditions,

making it suitable for various demanding applications, particularly in the aerospace and power generation industries.

Key Characteristics:

High-Temperature Strength: Retains mechanical properties at temperatures up to approximately 700°C (1292°F).

Oxidation and Corrosion Resistance: Excellent resistance to oxidation and corrosion in aggressive environments.

Fabricability: Can be easily formed, welded, and machined using conventional techniques.

Versatility: Ideal for applications such as gas turbines, heat exchangers, and combustion components.

Specification

UNS | W.Nr |

N07750 | 2.4669 |

Chemical Composition

Grade | % | Ni | Cr | Fe | Nb | Co | C | Mn | Si | S | Cu | Al | Ti | P |

X-750 | Min | Bal. | 14 | 5.0 | 0.7 | 0.4 | 2.25 | |||||||

Max | 17 | 9.0 | 1.2 | 1.00 | 0.08 | 1.00 | 0.50 | 0.01 | 0.5 | 1.0 | 2.75 | 0.02 |

Mechanical properties:(Minimum value at 20℃)

σb/MPa | Yield Strength σp0.2/MPa | Elongation σ5 /% |

910 | 550 | 25 |

Standard

Bar | Forging | Sheet/Strip | Wire |

ASTM B637

| ASTM B637 | AMS 5542 | AMS 5698 |

Applications:

Aerospace: Used in gas turbine components, such as blades and seals, due to its ability to withstand high temperatures and stress.

Nuclear Industry: Employed in reactor cores and other components where resistance to radiation and high temperatures is critical.

Oil and Gas: Utilized in downhole tubing and valves, where corrosion resistance is essential.

Chemical Processing: Suitable for heat exchangers, reactors, and other equipment exposed to harsh chemicals.

Industrial Furnaces: Used in components that require high-temperature strength and resistance to oxidation.

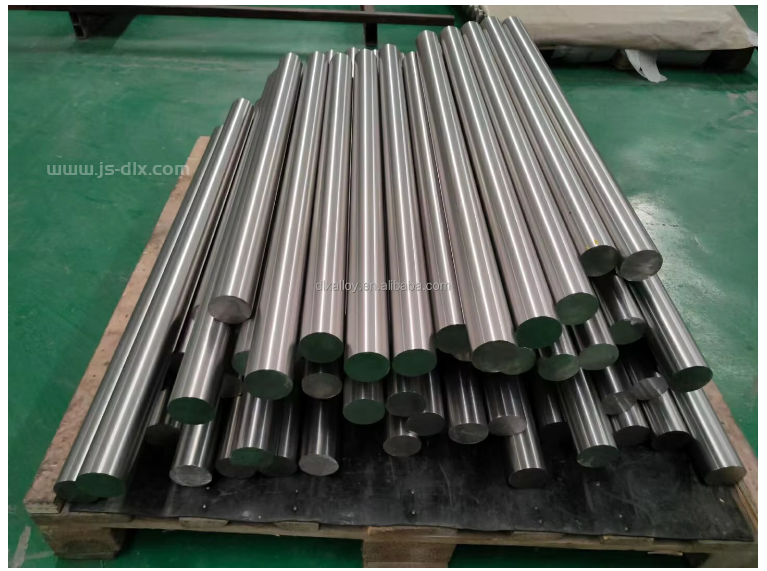

How To Produce Inconel x750 Bar?

Producing an Inconel X750 bar involves several key steps, including material selection, melting, forming, and finishing. Here's an overview of the process:

1. Material Selection

Raw Materials: Gather the necessary alloying elements, primarily nickel, chromium, iron, and small amounts of other elements like titanium and aluminum.

2. Melting

Induction or Electric Arc Furnace: The raw materials are melted in a controlled environment using either an induction furnace or an electric arc furnace to ensure homogeneity.

Alloy Composition: Monitor and adjust the composition as needed to meet the specifications for Inconel X750.

3. Casting

Ingot Casting: Pour the molten alloy into molds to form ingots. This can be done via sand casting or investment casting techniques.

Cooling: Allow the ingots to cool slowly to prevent cracking and ensure uniformity.

4. Forging

Hot Forging: The cooled ingots are heated and then forged into bars. This process improves mechanical properties by refining the grain structure.

Shaping: The bars are shaped to the desired dimensions through various forging techniques.

5. Heat Treatment

Solution Annealing: The forged bars are heated to a specific temperature, then rapidly cooled to dissolve any precipitates.

Aging: The bars are then aged at a lower temperature to enhance strength and stability, typically around 1300°F (700°C) for several hours.

6. Machining

Cutting and Shaping: The bars may be machined to precise dimensions using conventional machining techniques, such as turning, milling, and grinding.

Surface Finishing: Apply surface treatments as necessary to achieve the desired finish and surface quality.

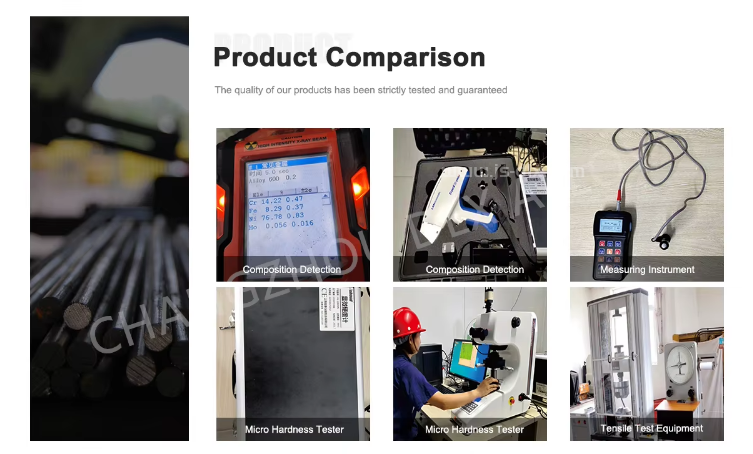

7. Inspection and Testing

Quality Control: Conduct non-destructive testing (NDT) and mechanical testing to ensure the bars meet the required specifications for strength, ductility, and corrosion resistance.

Documentation: Maintain records of the production process, material properties, and inspection results.

8. Packaging and Shipping

Final Inspection: Perform a final inspection before packaging.

Shipping: Package the bars for shipment to customers or further processing.

Our Advantages

FAQ

What is your working time?

Monday-Saturday : 7:30AM-17:00PM (Beijing time, GMT+08.00)We have public holiday during May.1-3, Oct.1-7 and Chinese New Year holiday . Pls email us during our holiday if u have any question.

mobile/whatsapp/skype/wechat:+8618961410953, Joyce

Do you provide free samples?

Yes, we can provide a free sample for testing,buyer should bear all the shipping costs.

What is your payment terms?

T/T,L/C,D/A,D/P,Western Union,MoneyGram,Paypal

What is the lead time?

Usually sample lead time is 7 days after payment has been confirmed.