Inconel bar Product Description:

Inconel bars, like other forms of Inconel Alloys, are known for their remarkable strength, corrosion resistance, and ability to perform under extreme conditions. These bars are typically used in environments that demand high-performance materials capable of withstanding high temperatures, corrosive substances, and mechanical stress.

The Inconel Alloy is commonly used in the production of Inconel 625 cladding, which is a type of protective layer that is applied to metal surfaces to prevent corrosion and wear. The Inconel Alloy is an ideal material for this application due to its high strength and resistance to corrosion.

In addition to its use in Inconel 625 cladding, the DLX Inconel Alloy is also used in a variety of other applications. It is commonly used in the aerospace industry for engine components, as well as in the chemical and petrochemical industries for pipes, valves, and fittings.

The DLX Inconel Alloy is produced in China, and is known for its high quality and consistency. It is a non-magnetic material, which makes it suitable for use in applications where magnetic properties are a concern. The thermal expansion coefficient of the Inconel Alloy is 13-17 µm/mK, which makes it suitable for use in applications where thermal stability is important.

The specific heat capacity of the DLX Inconel Alloy is 0.431 J/g-°C, which makes it suitable for use in applications where heat transfer is important. The Inconel Alloy also has excellent low temperature resistance, down to -253°C, which makes it suitable for use in cryogenic applications.

If you are looking for an Incoloy Alloy 20 plate sheet, the DLX Inconel Alloy is an excellent choice. It is a high-quality material that is suitable for use in a wide range of applications, and is known for its excellent corrosion resistance, thermal stability, and low temperature resistance.

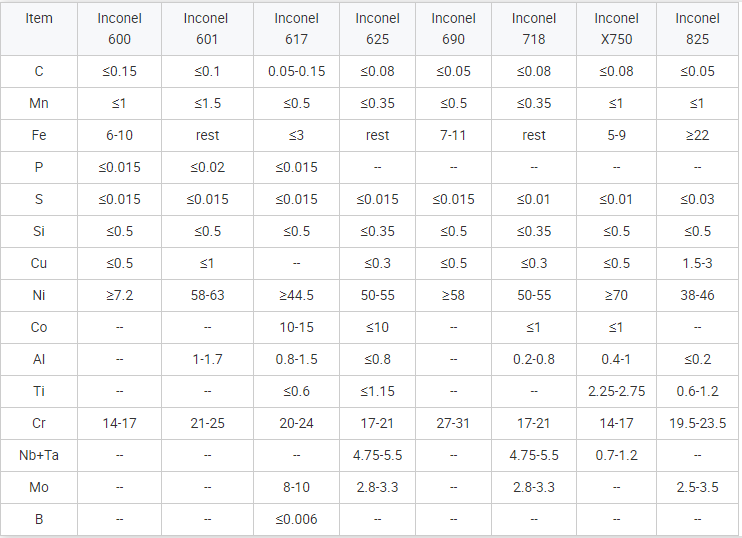

Common Inconel Grades for Bars:

Inconel 625 Bar: Known for its exceptional resistance to pitting, crevice corrosion, and oxidation, as well as its high strength. It is often used in marine, aerospace, and chemical processing applications.

Inconel 600 Bar: Excellent oxidation and corrosion resistance, particularly at elevated temperatures. It is used in furnace components, heat exchangers, and chemical processing.

Inconel 718 Bar: Offers high strength and corrosion resistance, with good weldability. It is widely used in aerospace and gas turbine engines, especially for components like turbine blades and rocket engines.

Inconel 601 Bar: Noted for its high-temperature oxidation resistance, making it suitable for applications in thermal processing, heat treatment, and gas turbines.

Key Characteristics of Inconel Bars:

Corrosion Resistance: Inconel bars offer outstanding resistance to a broad range of corrosive environments, including acids, alkalis, and seawater.

High-Temperature Performance: The bars retain their mechanical properties even at high temperatures, often above 1000°C (1832°F), making them suitable for use in heat-treating equipment, jet engines, and power generation.

Mechanical Strength: Inconel bars have excellent tensile strength, fatigue resistance, and creep resistance, allowing them to endure extreme mechanical stress.

Fabricability and Weldability: These bars can be easily fabricated, machined, and welded, with some alloys like Inconel 625 not requiring post-weld heat treatment.

Applications:

Aerospace: Inconel bars are used in high-stress applications such as jet engine components, gas turbines, and exhaust systems due to their high strength and heat resistance.

Chemical Processing: The bars are used in chemical plants for components exposed to corrosive chemicals and high temperatures, including heat exchangers and reactor vessels.

Marine and Offshore: Inconel bars are ideal for applications in seawater environments, where they resist corrosion and pitting, making them suitable for marine hardware and offshore platforms.

Nuclear Industry: Inconel bars are used in nuclear reactors and related equipment because of their ability to withstand radiation and extreme temperatures.

Sizes and Specifications:

Inconel bars are available in various shapes and sizes, including round bars, square bars, hexagonal bars, and flat bars. They are manufactured according to industry standards such as ASTM B446 for Inconel 625 and ASTM B166 for Inconel 600, ensuring quality and performance.

Product Description:

Our Inconel Alloy is made of alloy steel metal, a durable and versatile material that offers exceptional strength and excellent resistance to corrosion and oxidation. It is commonly used in chemical processing, aerospace, and marine applications, and other industries that require materials that can withstand extreme temperatures and harsh environments.

Our Inconel Alloy meets the ASTM and ASME standards, ensuring that it is manufactured to the highest quality standards. It undergoes rigorous testing and inspection to ensure that it meets the specific requirements of our clients.

One of the key features of our Inconel Alloy is its specific heat capacity of 0.431 J/g-°C. This means that it can absorb and release heat efficiently, making it an ideal material for use in heat exchangers, furnaces, and other high-temperature applications.

Another important feature of our Inconel Alloy is its thermal expansion rate of 13-17 µm/mK. This means that it can expand and contract uniformly in response to temperature changes, minimizing the risk of damage and deformation. This makes it a popular choice for applications that require materials that can withstand high temperatures and thermal cycling.

In conclusion, our Inconel Alloy is a high-quality alloy product that is ideal for use in high-temperature applications that require excellent corrosion resistance and durability. It is made of alloy steel metal, meets the ASTM and ASME standards, and has a specific heat capacity of 0.431 J/g-°C and a thermal expansion rate of 13-17 µm/mK. Contact us today to learn more about our Inconel Alloy and how it can benefit your business.

Customization:

Customize your DLX Inconel Alloy product according to your specific requirements with our product customization services. Our product is an alloy steel product made in China with the model number of Inconel Alloy. It is a high-quality alloy that can withstand low temperatures down to -253°C and has a melting range of 1332-1380 ℃. Our product meets the standard requirements of ASTM and ASME. The brand number for our product is Alloys 625 NS3306 NO6625 2.4856.

With our product customization services, you can optimize your product to meet your specific needs. Our alloy agent in steel can help you achieve the desired characteristics for your application. Choose from a variety of customization options to create a unique product that fits your requirements.

Our product is also commonly known as Incoloy Alloy 20 Plate Sheet. Trust in DLX for all your alloy steel product needs.

Support and Services:

The Inconel Alloy product technical support and services include:

Expert consultation on product selection and application

Guidance on proper handling, storage, and transportation of the product

Assistance with product installation and maintenance

Technical troubleshooting and problem-solving

Training programs for end-users and technicians

Warranty support and product repair services

Packing and Shipping:

Product Packaging:

The Inconel Alloy product will be packed in a sturdy wooden crate to ensure safe transportation.

The crate will be lined with foam to prevent any damage during transit.

The product will be securely strapped to the base of the crate to ensure it doesn't move during shipping.

Shipping:

The Inconel Alloy product will be shipped via air or sea depending on the customer's preference.

The shipping cost will depend on the destination and mode of transportation.

The customer will be provided with a tracking number to monitor the delivery status of their product.

About Us:

Our company Principle is " Quality first, Customer first".

CHANGZHOU DLX ALLOY CO, LTD was established in 2002 and has got Iso9001 International Quality Management System Certificate and SGS Certificate. Our factory is professional in researching and producing special alloy material. From melting, drawing, heat treatment, finishing and testing .We offer nickel-based, copper-based, and iron-based alloys, including super alloy, welding materials, anti-corrosion alloy, precision alloy, FeCrAl alloy, NiCr alloy, CuNi alloy, thermocouple and etc, in the form of wire, strip, ribbon, bar, tube, plate.

FAQ:

Q: What is the brand name of this product?

A: The brand name of this product is DLX.

Q: What is the model number of this product?

A: The model number of this product is Inconel Alloy.

Q: Where is this product manufactured?

A: This product is manufactured in China.

Q: What are the applications of Inconel Alloy?

A: Inconel Alloy is widely used in high-temperature applications such as gas turbine engines, chemical processing, and nuclear reactors.

Q: What are the physical properties of Inconel Alloy?

A: Inconel Alloy has high strength, excellent resistance to corrosion and oxidation, and good mechanical properties at elevated temperatures.