Basic Info.

| Model NO. | Haynes 230 | Production Capacity | 1000kg Per Week |

| Shape | Wrie, Pipe,Bar,Strip, Plate | Surface | Bright/Black |

| Technique | Cold Treatment | Manufacturing Process | Solution Treatment |

| Specification | GB, AISI, ASTM, DIN, EN, SUS, UNS | Trademark | DLX |

| Origin | Changzhou, Jiangsu, China | Transport Package | Carton or Wooden Case |

Product Description

Haynes 230 is a nickel-chromium-tungsten-molybdenum alloy known for its exceptional combination of high-temperature strength and oxidation resistance. Here's a breakdown of its key properties and applications:

Properties

High-Temperature Strength: Haynes 230 maintains its mechanical properties even at elevated temperatures, performing well in environments up to 2100°F (1150°C).

Oxidation Resistance: The alloy exhibits excellent oxidation resistance, making it suitable for long-term exposure to extreme temperatures without significant degradation.

Fabricability: It is easily fabricated and welded, which makes it suitable for producing complex components.

Carburization and Nitridation Resistance: Haynes 230 resists carburization and nitridation, common in high-temperature processing environments (High Temp Metals).

Applications

Aerospace: Used in turbine engines, combustor cans, and other hot section components due to its ability to withstand extreme temperatures.

Industrial Heating: Ideal for use in heat exchangers, furnace parts, and other high-temperature equipment.

Chemical Processing: Frequently used in equipment that requires stability under both oxidizing and reducing conditions.

Application field:

High temperature components, such as turbine blades, guide vanes, turbine disks, high pressure compressor disks,machine manufacturing and combustion chambers used in the manufacture of aviation, naval and industrial gas turbines.

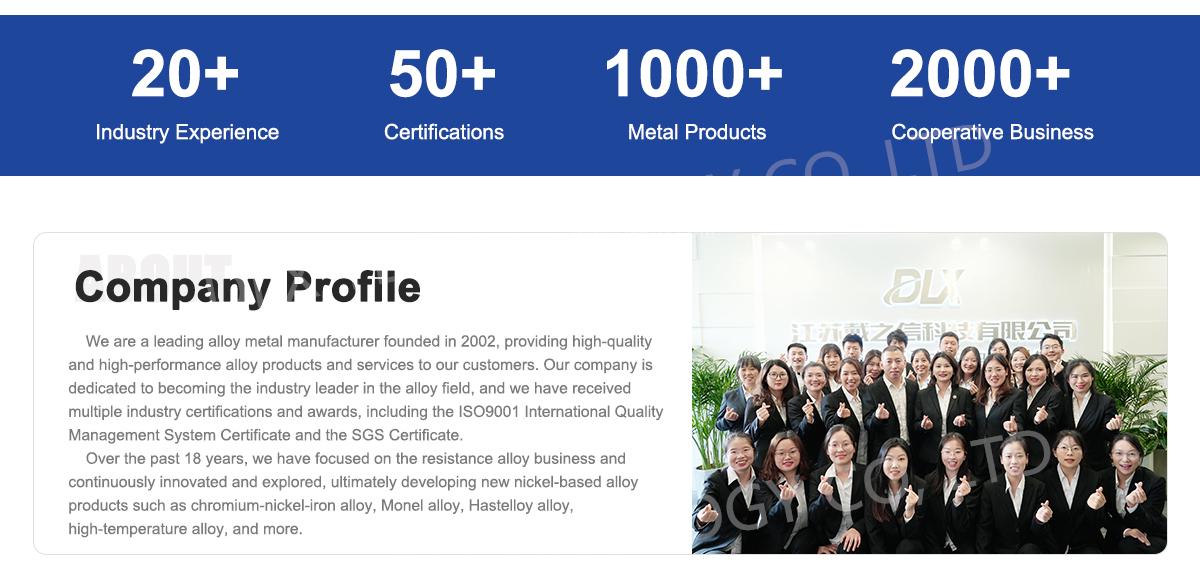

About Us:

Our company Principle is " Quality first, Customer first".

CHANGZHOU DLX ALLOY CO, LTD was established in 2002 and has got Iso9001 International Quality Management System Certificate and SGS Certificate. Our factory is professional in researching and producing special alloy material. From melting, drawing, heat treatment, finishing and testing .We offer nickel-based, copper-based, and iron-based alloys, including super alloy, welding materials, anti-corrosion alloy, precision alloy, FeCrAl alloy, NiCr alloy, CuNi alloy, thermocouple and etc, in the form of wire, strip, ribbon, bar, tube, plate.

FAQs:

Question: Are you a trading company or manufacturer?

Answer: We're manufacturer.

Question: Could you help to design the product?

Answer: Yes, we have excellent R&D team, OEM/ODM orders are all welcome.

Question: Could you supply samples?

Answer: Yes, wecould supply samples according to your requirement.

Question: could we visit your factory?

Answer: Sure, factory visit is warmly welcome.