Product Description

Alloy L605 rod, also known as HAYNES® 25, stands out as the strongest among the fabricable cobalt alloys and can operate continuously at temperatures up to 1800°F. Its extensive and long-standing use has made it the subject of numerous studies aimed at understanding its properties under a wide range of conditions. As a result, Alloy L605 is one of the most thoroughly characterized materials in its category. Similar to other superalloys like Alloy X and Alloy 625, it experiences a reduction in room temperature ductility after extended exposure to intermediate temperatures.

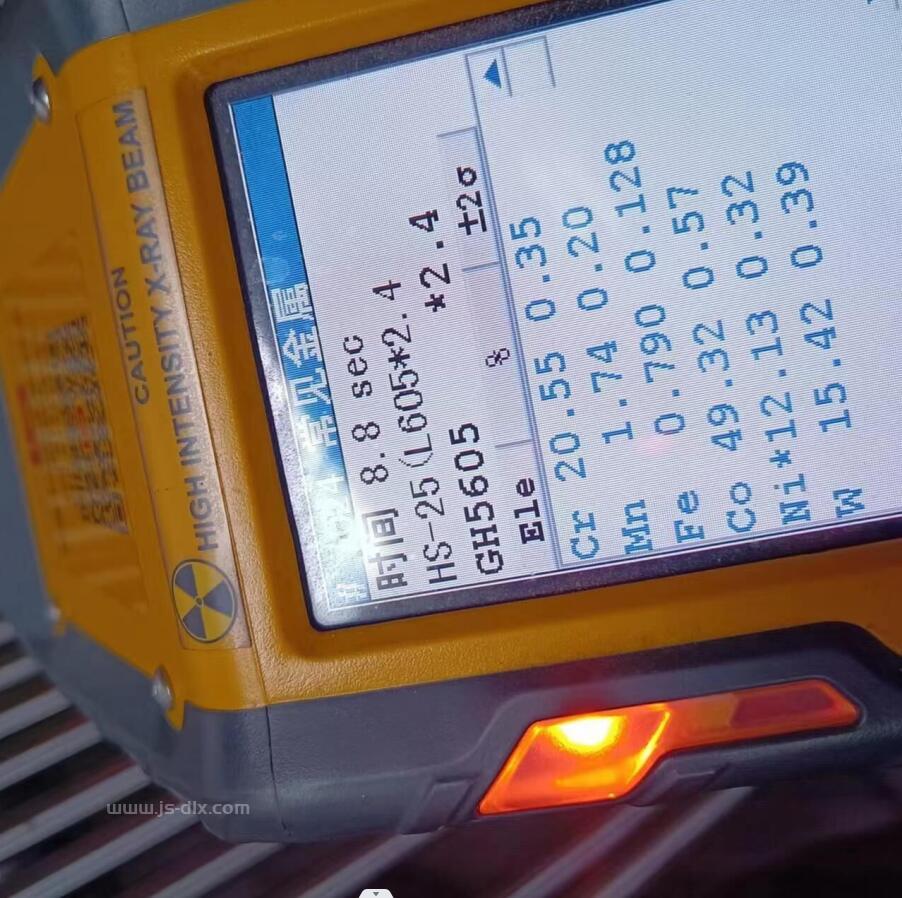

Chemical Composition For L605 Rod

| Carbon | 0.05-0.15 |

| Manganese | 1.0-2.0 |

| Silicon | 0.40 max. |

| Chromium | 19.0-21.0 |

| Nickel | 9.0-11.0 |

| Tungsten | 14.0-16.0 |

| Phosphorus | 0.040 max. |

| Sulfur | 0.030 max. |

| Iron | 3.0 max. |

| Cobalt | Balance* |

Physical Constants for L605 Rod

| Density | lb/in3 | 0.335 |

| g/cm3 | 9.27 | |

| Melting Range | °F | 2426-2570 |

| °C | 1330-1410 | |

| Specific Heat | at 70°F, Btu/lb°F | 0.092 |

| at 21 °C, J/kg°C | 385 | |

| Permeability at 200 oersted | 1.002 | |

| Thermal Conductivity | Btu•in/ft2•h•°F | 65 |

| W/m•°C | 9.4 | |

| Electrical Resistivity | (75°F), ohm•circ mil/ft | 533.2 |

| (24°C), microohm-m | 0.886 | |

Properties For L605 Rod

25) is a cobalt-based superalloy known for its excellent mechanical properties and high-temperature capabilities. Here are the key properties of Alloy L605:

25) is a cobalt-based superalloy known for its excellent mechanical properties and high-temperature capabilities. Here are the key properties of Alloy L605:1. High-Temperature Strength

Retains high strength and good oxidation resistance at temperatures up to 1800°F (980°C).

Useful in high-stress applications where sustained high temperatures are a factor.

2. Oxidation and Corrosion Resistance

Excellent oxidation resistance in air up to 2000°F (1093°C).

Resists corrosion in various environments, including oxidizing and reducing atmospheres, as well as saltwater.

3. Wear and Galling Resistance

Exhibits good resistance to wear and galling, which is useful in parts subjected to friction at elevated temperatures.

4. Fabricability

Although a strong material, Alloy L605 is still fabricable through various methods, including forming, welding, and machining.

5. Creep and Fatigue Resistance

High resistance to creep and fatigue at elevated temperatures, making it ideal for components that experience thermal cycling and mechanical stress over time.

6. Room Temperature Ductility

Shows good ductility at room temperature, although prolonged exposure to intermediate temperatures can reduce this property (common in superalloys).

7. Chemical Composition

Primary elements include cobalt (Co), chromium (Cr), tungsten (W), nickel (Ni), and a small percentage of iron (Fe).

The alloy contains around 10-20% tungsten, which contributes to its strength and corrosion resistance.

8. Applications

Frequently used in gas turbine engine components, combustion chambers, afterburners, and other high-temperature applications in aerospace and power generation industries.

These properties make Alloy L605 highly suitable for high-performance applications in extreme environments, where both heat and mechanical stress are present.

L605 Rod is a nickel-based high-temperature resistant alloy known for its excellent mechanical properties, corrosion resistance, and stability at elevated temperatures. It is primarily used in industries where materials are exposed to extreme heat, pressure, and corrosive environments. Common application areas for GH5605 include:

Aerospace industry: Used in turbine blades, combustion chambers, and other components of aircraft engines and gas turbines that require high strength and resistance to oxidation at high temperatures.

Power generation: Employed in the manufacturing of parts for gas turbines and nuclear reactors due to its ability to maintain strength under thermal stress and resist oxidation.

Petrochemical industry: Used in high-temperature chemical processing equipment, such as reactors and heat exchangers, due to its corrosion resistance in aggressive environments.

Marine applications: Applied in marine engines and offshore platforms that require materials with high resistance to saltwater corrosion and heat.

Automotive industry: Used in the production of turbochargers and exhaust valves for high-performance engines.

GH5605's versatility in high-temperature environments makes it a preferred choice for critical components in these industries.