Welcome to Changzhou DLX Alloy Co., Ltd.

Email:sales8@dlx-alloy.com Mobile/Whatsapp:+86 199 0611 9641

Specialized manufacturer of heaters, thermocouples and titanium,over 20 years.

Welcome to Changzhou DLX Alloy Co., Ltd.

Email:sales8@dlx-alloy.com Mobile/Whatsapp:+86 199 0611 9641

Specialized manufacturer of heaters, thermocouples and titanium,over 20 years.

Whatsapp:+86 199 0611 9641

Email:sales8@dlx-alloy.com

Add:NO.32 West Taihu Road, Xinbei District, Changzhou, Jiangsu,China

Hastelloy Alloys

Product Details

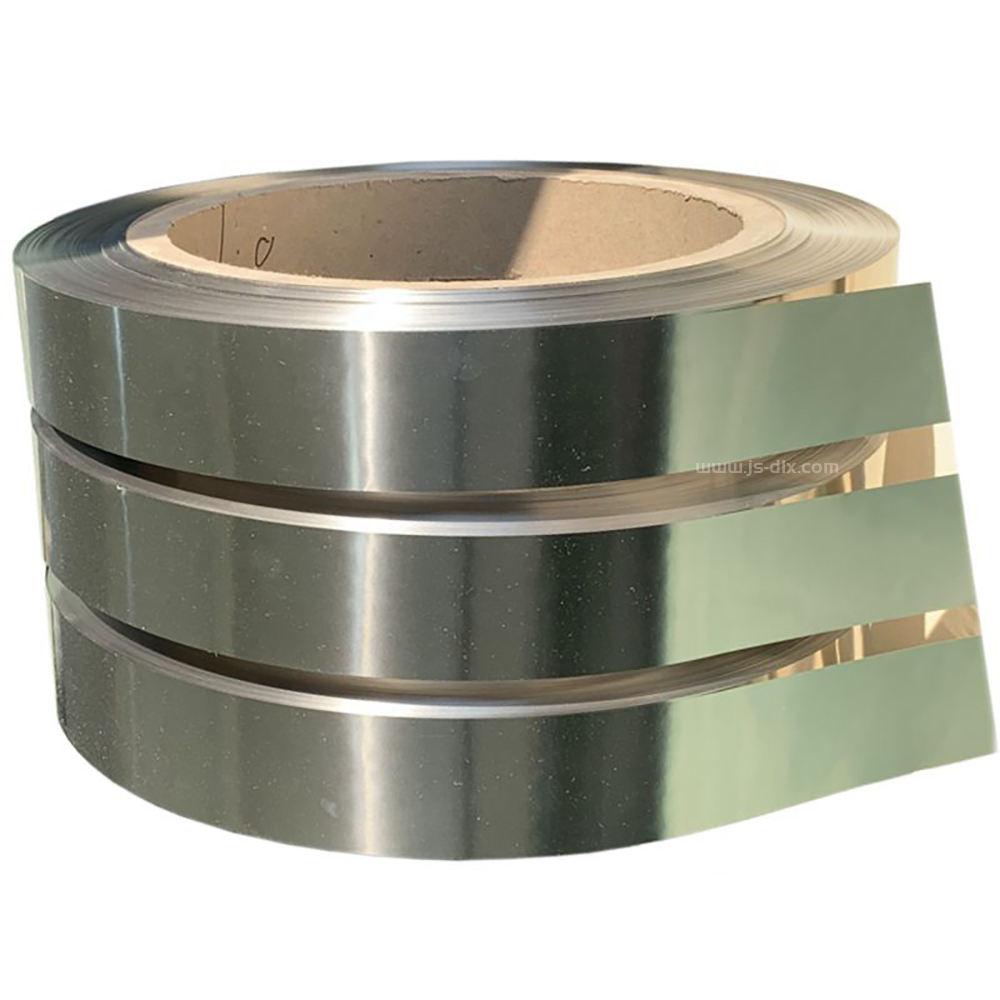

High Oxidation Resistance Hastelloy Alloy N (UNS N10003) Coil Strip

Hastelloy N is a nickel-based alloy developed specifically for high-temperature applications and environments where resistance to molten fluoride salts is crucial. Initially developed in the 1950s for use in molten salt reactors (MSRs) as part of the U.S. nuclear energy program, Hastelloy N remains an important material in nuclear and chemical processing industries due to its excellent resistance to both high temperatures and corrosion.

High-Temperature Stability: Hastelloy N exhibits excellent stability at high temperatures, making it suitable for applications where temperatures can exceed 1000°F (540°C). The alloy maintains its strength and mechanical properties even under prolonged exposure to high temperatures, which is critical in high-temperature nuclear and chemical environments.

Resistance to Molten Fluoride Salts: One of the defining features of Hastelloy N is its exceptional resistance to corrosion in molten fluoride salts, such as those used in molten salt reactors. These reactors use molten salts as both coolant and fuel, and the material used must withstand this harsh environment without degrading over time. Hastelloy N meets this requirement, which is why it was chosen for early molten salt reactor experiments.

Good Oxidation Resistance: In addition to its resistance to molten salts, Hastelloy N also provides good resistance to oxidation in air, making it suitable for applications where the material may be exposed to both corrosive environments and oxidizing atmospheres.

Low Creep and Fatigue: Hastelloy N exhibits low creep and fatigue under high-stress and high-temperature conditions, contributing to its durability in applications like nuclear reactors, where materials are subjected to extreme conditions over long periods.

Ease of Fabrication: Like other nickel-based alloys, Hastelloy N can be easily fabricated using standard techniques. It can be welded and machined without excessive difficulty, which facilitates its use in complex industrial applications.

Nuclear Reactors: The most notable application of Hastelloy N is in molten salt reactors (MSRs). MSRs operate at high temperatures and utilize molten fluoride salts as both coolant and fuel. Hastelloy N’s ability to withstand corrosion in this environment makes it an ideal choice for reactor components such as heat exchangers, piping, and containment vessels.

Chemical Processing: Hastelloy N is also used in chemical processing industries, particularly in environments involving hot fluoride salts or other highly corrosive substances. It can be found in equipment like reactors, heat exchangers, and piping systems that are exposed to harsh chemicals and elevated temperatures.

High-Temperature Environments: Hastelloy N's ability to maintain its mechanical properties at high temperatures makes it suitable for other high-temperature applications, including furnaces and industrial heating systems.

Aerospace and Energy: In the aerospace and energy sectors, Hastelloy N is used in components that require high-temperature resistance, such as turbine engines, gas turbines, and other heat-intensive applications.

Exceptional resistance to molten fluoride salts: Ideal for use in MSRs and chemical processing involving such salts.

High-temperature stability: Capable of maintaining its mechanical properties at elevated temperatures.

Good oxidation resistance: Performs well in environments where oxidation could be a concern.

Durability: Offers excellent creep and fatigue resistance under high stress and temperature conditions

Hastelloy N is a highly specialized nickel-based alloy designed for high-temperature and corrosive environments, particularly where exposure to molten fluoride salts is a concern. Initially developed for nuclear reactors, the alloy has found applications in chemical processing, aerospace, and other industries where extreme conditions prevail. With its exceptional resistance to corrosion, oxidation, and thermal stress, Hastelloy N remains a critical material in high-performance applications that demand both reliability and longevity.

Why Hastelloy N Alloy Are Very Suitable For Nuclear Applications?

Hastelloy N is particularly well-suited for nuclear applications, especially in environments involving molten salts, due to a combination of its unique properties and characteristics. Here’s a detailed explanation of why Hastelloy N is an ideal choice for nuclear applications:

Primary Suitability: One of the most critical requirements in nuclear reactors, especially molten salt reactors (MSRs), is the ability to withstand the corrosive nature of molten fluoride salts. These salts are used as both coolant and fuel in MSRs, which operate at high temperatures. Hastelloy N exhibits exceptional resistance to these corrosive salts, making it one of the few materials capable of enduring long-term exposure in such environments without significant degradation.

Protection Against Corrosion: The alloy’s composition, which includes nickel, molybdenum, and chromium, provides it with excellent resistance to chemical attacks from molten salts. This helps prevent issues like cracking or material loss, which are critical concerns in nuclear environments where safety and material integrity are paramount.

Sustaining Mechanical Properties: Hastelloy N is designed to maintain its mechanical properties even at elevated temperatures, which are typical in nuclear reactors. It can withstand temperatures exceeding 1000°F (540°C) without losing its strength, which is crucial in reactors that operate at high thermal conditions.

Creep and Fatigue Resistance: Nuclear reactors often subject materials to high stresses over long periods. Hastelloy N offers excellent resistance to creep (the tendency of a material to deform permanently under mechanical stress) and fatigue (weakening of material caused by repeated stress cycles). This ensures the structural integrity of critical components under the reactor’s harsh operating conditions.

Neutron Economy: In nuclear reactors, it is essential to minimize the absorption of neutrons by the structural materials, as neutrons are necessary for sustaining the nuclear fission chain reaction. Hastelloy N has a relatively low neutron absorption cross-section compared to other materials, meaning it does not significantly interfere with the reactor’s neutron economy. This is particularly important in thermal reactors, where the efficient utilization of neutrons is critical for the reactor’s performance and safety.

Radiation Stability: Materials in nuclear reactors are constantly bombarded by radiation, which can cause changes in the microstructure of the material, leading to embrittlement and other forms of degradation. Hastelloy N has been shown to resist radiation damage better than many other materials, maintaining its mechanical properties and corrosion resistance over extended periods of exposure to high radiation levels.

Reduced Helium Embrittlement: When exposed to neutron radiation, materials can sometimes generate helium within their structure, leading to embrittlement. Hastelloy N is engineered to minimize this effect, reducing the risk of embrittlement over the reactor’s operational life.

Ease of Manufacturing: Hastelloy N can be easily fabricated into complex shapes and components required for nuclear reactors. Its good weldability allows for the construction of large and intricate structures without compromising material integrity. This is essential in nuclear reactor designs, where components must meet stringent safety and reliability standards.

Minimal Risk of Phase Formation: During welding and heat treatment, certain alloys can form undesirable phases that reduce corrosion resistance and mechanical properties. Hastelloy N is less prone to forming these detrimental phases, making it a reliable choice for the construction of nuclear reactors.

Prolonged Service Life: Nuclear reactors are designed to operate for many years, often decades, without significant maintenance. Hastelloy N’s combination of high-temperature strength, corrosion resistance, and resistance to radiation damage ensures that reactor components made from this alloy can last for extended periods, reducing the need for frequent replacements or repairs.

Safety and Reliability: The longevity of Hastelloy N in corrosive and high-radiation environments contributes to the overall safety and reliability of nuclear reactors. By maintaining its structural integrity and resistance to degradation, the alloy helps minimize the risk of failures that could lead to accidents or downtime.

Extensive Research and Development: Hastelloy N was specifically developed in the 1950s and 1960s for use in molten salt reactors under the U.S. nuclear energy program. Its properties were fine-tuned to address the unique challenges posed by nuclear environments, and it has undergone extensive testing and validation in these applications.

Proven Track Record: Hastelloy N has been successfully used in various experimental nuclear reactors, particularly MSRs, demonstrating its effectiveness in real-world conditions. This proven track record makes it a trusted material in the nuclear industry.

Hastelloy N is particularly suitable for nuclear applications due to its exceptional resistance to molten fluoride salts, high-temperature stability, low neutron absorption, resistance to radiation damage, and long-term durability. These characteristics make it an ideal choice for critical components in nuclear reactors, especially in molten salt reactors, where both corrosion resistance and material stability under extreme conditions are essential. Its development history and proven performance further solidify its position as a reliable material in the nuclear energy sector.

s.

What is your working time?

Monday-Saturday : 7:30AM-17:00PM (Beijing time, GMT+08.00)

We have public holiday during May.1-3, Oct.1-7 and Chinese New Year holiday . Pls email us during our holiday if u have any question.

Do you provide free samples?

Yes, we can provide a free sample for testing,buyer should bear all the shipping costs.

What is your payment terms?

T/T,L/C,D/A,D/P,Western Union,MoneyGram,Paypal

What is the lead time of sample order?

Usually sample lead time is 7-15 days after payment has been confirmed.