Welcome to Changzhou DLX Alloy Co., Ltd.

Email:sales8@dlx-alloy.com Mobile/Whatsapp:+86 199 0611 9641

Specialized manufacturer of heaters, thermocouples and titanium,over 20 years.

Welcome to Changzhou DLX Alloy Co., Ltd.

Email:sales8@dlx-alloy.com Mobile/Whatsapp:+86 199 0611 9641

Specialized manufacturer of heaters, thermocouples and titanium,over 20 years.

Whatsapp:+86 199 0611 9641

Email:sales8@dlx-alloy.com

Add:NO.32 West Taihu Road, Xinbei District, Changzhou, Jiangsu,China

Hastelloy Alloys

Product Details

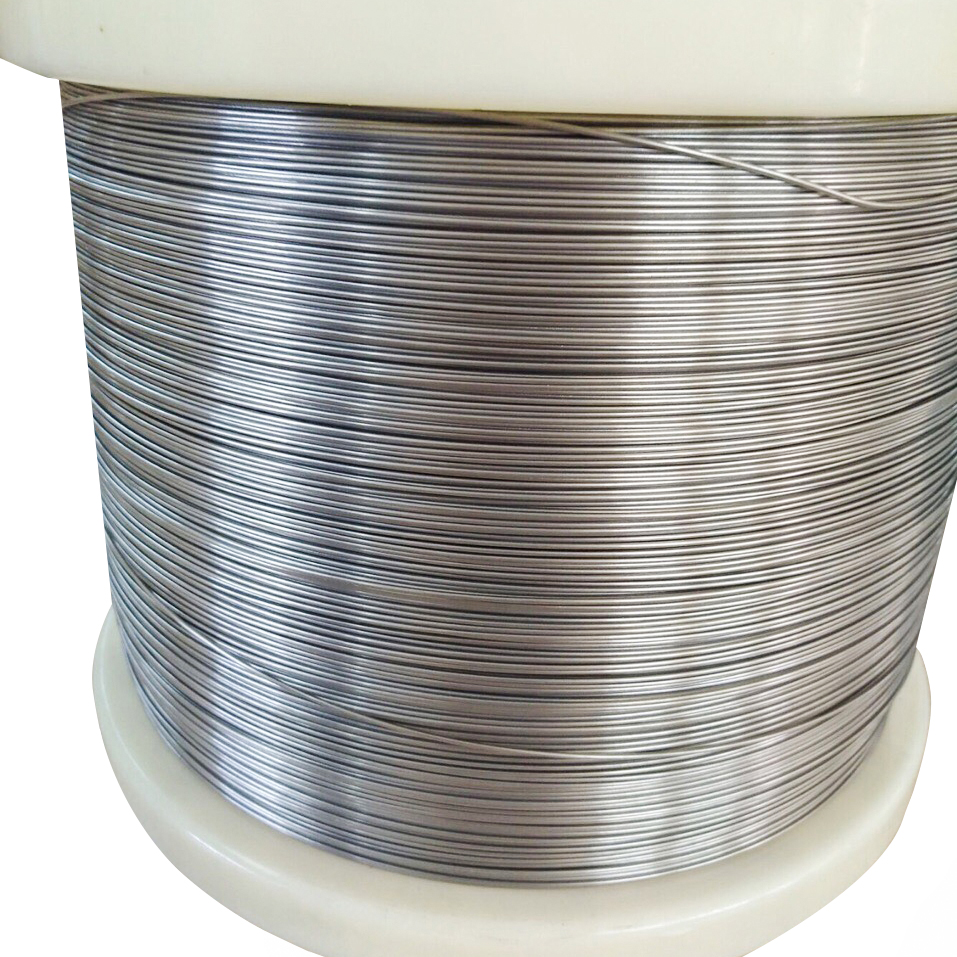

UNS N06455 Hastelloy C-4 Alloy Bright Soft / Hard Condition Wire

Hastelloy C4 wire is a high-performance nickel-based alloy wire made from Hastelloy C4, which is specifically designed for excellent resistance to corrosion in a variety of challenging environments. This alloy is particularly effective in applications involving reducing and oxidizing media, making it a versatile choice for several industrial sectors.

Hastelloy C-4 wire has several special characteristics that distinguish it from other Hastelloy alloy wires. Here are the key features:

1. Superior Corrosion Resistance

Versatility: Hastelloy C-4 offers excellent resistance to both reducing and oxidizing environments, making it suitable for a wider range of applications compared to other Hastelloy Alloys.

Localized Corrosion: It has enhanced resistance to pitting and crevice corrosion, particularly in chloride-containing environments.

2. High-Temperature Stability

Strength Retention: C-4 maintains its mechanical properties at elevated temperatures, which is essential for applications in high-heat environments.

Oxidation Resistance: The alloy exhibits good resistance to oxidation at elevated temperatures, ensuring longevity in extreme conditions.

3. Stress Corrosion Cracking Resistance

Minimized Risk: Hastelloy C-4 is designed to resist stress corrosion cracking, making it suitable for high-stress applications in corrosive environments where other alloys might fail.

4. Weldability

Ease of Fabrication: C-4 is easily weldable, and its corrosion resistance is maintained even after welding. This is crucial for creating complex structures and components without compromising integrity.

5. Ductility and Formability

Good Ductility: The alloy exhibits excellent ductility, allowing for easy shaping and forming processes, which is beneficial in various manufacturing applications.

6. Lower Carbon Content

Reduced Sensitivity: Compared to other Hastelloy alloys, C-4 has a lower carbon content, which reduces the risk of carbide precipitation during welding. This characteristic enhances its corrosion resistance in welded structures.

7. Resistance to a Wide Range of Chemicals

Chemical Compatibility: Hastelloy C-4 demonstrates compatibility with a broad spectrum of aggressive chemicals, including sulfuric and hydrochloric acids, which may not be as effectively handled by other alloys.

8. Long-Term Performance

Durability: The combination of its properties ensures long-term performance in harsh environments, making it a reliable choice for critical applications.

Summary

Hastelloy C-4 wire stands out due to its exceptional corrosion resistance, high-temperature stability, and resistance to stress corrosion cracking. Its weldability, ductility, and compatibility with a wide range of chemicals further enhance its appeal compared to other Hastelloy alloy wires, making it a preferred choice in various demanding applications.

| Hastelloy Grade | Hastelloy B | Hastelloy C-276 | Hastelloy C-4 | Hastelloy C-22 | Hastelloy C-59 | Hastelloy G | Hastelloy X |

| Corresponding brand | N10001/ NS321/ ONl65Mo28Fe5/ VN12MV | N10276 / 2.4819/ NS334 / CW12MW | N06455 / 2.4610I 00Cr16Ni65Mo16Ti / NS335 | N06022 / 2.4602/ NS3308 | N06059 / 2.4605/ NS3311 / Alloy59 | N06007 / 2.4618/ NS3402 | N06002 / 2.4665/ GH3536 / GH32 |

| Chemical composition% | |||||||

| C≤ | 0.05 | 0.01 | 0.015 | 0.015 | 0.01 | 0.05 | 0.05-0.15 |

| Mn≤ | 1 | 1 | 1 | 0.5 | 0.5 | 1.0-2.0 | 1 |

| P≤ | 0.04 | 0.04 | 0.04 | 0.02 | 0.015 | 0.04 | 0.04 |

| S≤ | 0.03 | 0.03 | 0.03 | 0.02 | 0.01 | 0.03 | 0.03 |

| Si≤ | 1 | 0.08 | 0.08 | 0.08 | 0.01 | 1 | 1 |

| Cr≤ | ≤1 | 14.5-16.5 | 14.0-18.0 | 14.0-18.0 | 22.0-24.0 | 21.0-23.5 | 20.5-23.0 |

| Ni≤ | the base | the base | the base | the base | the base | the base | the base |

| Mo | 26.0-30.0 | 15.0-17.0 | 14.0-17.0 | 12.5-14.5 | 15.0-16.5 | 5.5-7.5 | 8.0-10.0 |

| Cu | ≤0.50 | 1.5-2.5 | |||||

| N | W:3.0-4.5 | W:2.5-3.5 | W:≤1.0 | W:0.2-1.0 | |||

| Nb | 1.75-2.50 | ||||||

| Other | V:0.20-0.40 Co:≤2.50 Fe:4.0-60. | V:≤0.35 Co:≤2.50 Fe:4.0-7.0 | Ti:≤0.70 Co:≤2.0 Fe:≤3.0 | V:≤0.35 Co:≤2.5 Fe:2.0-6.0 | AI:0.10-0.40 Co:≤0.30 Fe:≤1.50 | Co:≤2.5 Fe:≤18.0-21.0 | Co:≤0.5-2.5 Fe:≤17.0-20.0 |

Application of Hastelloy Alloy Wire:

Hastelloy C22 wire is used in various demanding applications due to its excellent corrosion resistance and versatility. Here are some key applications:

1. Chemical Processing

Reactors and Heat Exchangers: Used in systems handling aggressive chemicals, including acids and chlorides.

Piping and Valves: Suitable for transporting corrosive fluids safely.

2. Pharmaceuticals

Manufacturing Equipment: Ideal for equipment that requires high purity and resistance to corrosion, ensuring product integrity.

3. Oil and Gas Industry

Downhole Tubing: Employed in oil extraction environments where resistance to corrosive fluids is crucial.

Offshore Platforms: Components exposed to seawater and harsh conditions.

4. Marine Applications

Seawater Systems: Used in pumps, valves, and other components exposed to marine environments due to its excellent resistance to saltwater corrosion.

5. Nuclear Industry

Reactor Components: Suitable for various parts of nuclear reactors, where durability and resistance to radiation and heat are essential.

6. Power Generation

Gas Turbines: Utilized in components that operate at high temperatures and require resistance to oxidation and corrosion.

7. Food Processing

Processing Equipment: Used in food manufacturing environments where cleanliness and corrosion resistance are vital.

8. Aerospace

Jet Engine Components: Employed in parts exposed to high temperatures and corrosive environments.

Hastelloy C22 wire’s exceptional properties make it a preferred choice in these industries, ensuring reliability and durability in challenging conditions.

FAQ:

What is your working time?

Monday-Saturday : 7:30AM-17:00PM (Beijing time, GMT+08.00)

We have public holiday during May.1-3, Oct.1-7 and Chinese New Year holiday . Pls email us during our holiday if u have any question.

Do you provide free samples?

Yes, we can provide a free sample for testing,buyer should bear all the shipping costs.

What is your payment terms?

T/T,L/C,D/A,D/P,Western Union,MoneyGram,Paypal

What is the lead time of sample order?

Usually sample lead time is 7 days after payment has been confirmed.