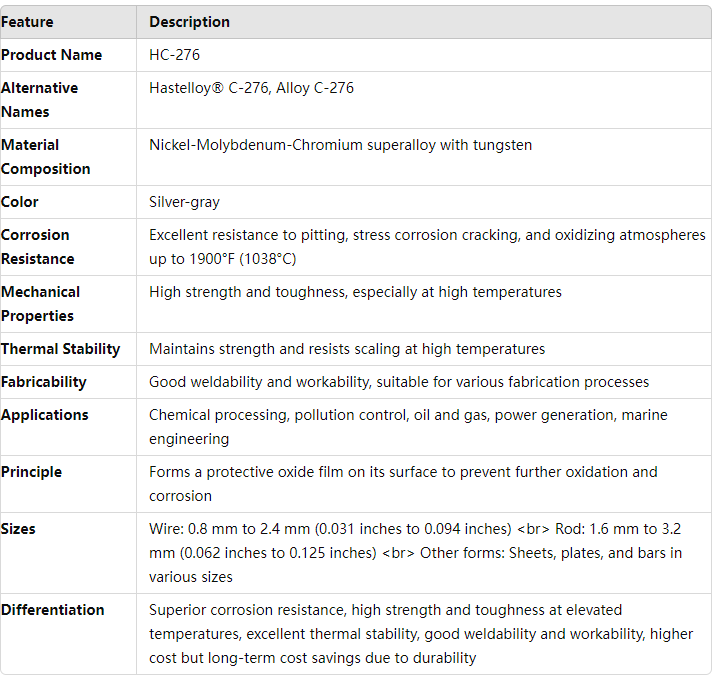

HC-276 Alloy Series

Product Name:

HC-276

Alternative Names:

Hastelloy® C-276, Alloy C-276

Material Composition:

HC-276 is a nickel-molybdenum-chromium superalloy with an addition of tungsten designed to have excellent corrosion resistance in a wide range of severe environments.

Color:

Silver-gray

Properties:

Corrosion Resistance: Excellent resistance to pitting, stress corrosion cracking, and oxidizing atmospheres up to 1900°F (1038°C).

Mechanical Properties: High strength and toughness, particularly in high-temperature environments.

Thermal Stability: Maintains strength and resists scaling at high temperatures.

Fabricability: Good weldability and workability, making it suitable for various fabrication processes including welding and machining.

Applications:

Chemical Processing: Used in chemical processing equipment due to its ability to withstand harsh chemicals.

Pollution Control: Employed in flue gas desulfurization systems.

Oil and Gas: Used in sour gas service and other oil and gas extraction processes.

Power Generation: Applied in power plants for heat exchangers and piping systems.

Marine Engineering: Utilized in marine environments due to its resistance to seawater corrosion.

Principle:

HC-276 alloy operates on the principle of forming a protective oxide film on its surface, which prevents further oxidation and corrosion. The presence of chromium and molybdenum enhances this protective layer, while tungsten adds additional resistance to localized corrosion.

Sizes:

Wire: Typically available in diameters ranging from 0.8 mm to 2.4 mm (0.031 inches to 0.094 inches).

Rod: Available in diameters from 1.6 mm to 3.2 mm (0.062 inches to 0.125 inches).

Other Forms: Sheets, plates, and bars are available in various sizes according to specific industrial requirements.

Product Differentiation of HC-276 Alloy Series

The HC-276 alloy series stands out in several key aspects that differentiate it from other alloys. These differences include its unique composition, superior properties, and specific applications, which are highlighted below:

1. Composition:

Nickel-Molybdenum-Chromium Base: The HC-276 alloy is primarily composed of nickel, molybdenum, and chromium, with the addition of tungsten. This combination provides a robust resistance to various types of corrosion.

Tungsten Addition: The presence of tungsten enhances the alloy's resistance to localized corrosion such as pitting and crevice corrosion, which is not as prominent in other alloys.

2. Corrosion Resistance:

Superior Corrosion Resistance: HC-276 exhibits exceptional resistance to both oxidizing and reducing environments, outperforming many other nickel-based alloys. It resists the formation of grain boundary precipitates in the weld heat-affected zone, maintaining corrosion resistance in the as-welded condition.

Stress Corrosion Cracking: It has outstanding resistance to stress corrosion cracking in chloride-bearing solutions, making it highly reliable in marine and chemical processing applications.

3. Mechanical Properties:

High Strength and Toughness: HC-276 maintains high strength and toughness at elevated temperatures, which is a significant advantage over other alloys that may lose mechanical properties under similar conditions.

Thermal Stability: It provides excellent thermal stability and oxidation resistance at high temperatures, which is crucial for high-temperature applications.

4. Fabricability:

Weldability: HC-276 offers good weldability, which simplifies fabrication and repair processes. Unlike some alloys, it does not require post-weld heat treatment to maintain its properties.

Workability: The alloy can be readily formed and fabricated, making it versatile for various industrial applications.

5. Applications:

Chemical Processing: HC-276 is preferred in chemical processing environments where harsh chemicals are present, outperforming other alloys that may suffer from rapid corrosion.

Marine Engineering: Its exceptional resistance to seawater corrosion makes it more suitable for marine applications compared to other alloys.

Oil and Gas: The alloy's resistance to sour gas environments differentiates it from other materials that may not perform as well under similar conditions.

6. Cost and Availability:

Cost: Due to its unique composition and superior properties, HC-276 may be more expensive than some other alloys. However, its durability and long-term performance can result in cost savings by reducing the need for frequent replacements and maintenance.

Availability: HC-276 is available in various forms including wire, rod, sheet, and plate, providing flexibility for different manufacturing needs.

In summary, the HC-276 alloy series differentiates itself through its unique composition, superior corrosion resistance, excellent mechanical properties, and versatility in a wide range of applications. These attributes make it a preferred choice for demanding environments where other alloys may fall short.

Company introduction:

CHANGZHOU DLX ALLOY CO, LTD was established in 2002 and has got Iso9001 International Quality Management System Certificate and SGS Certificate. Our factory is professional in researching and producing special alloy material. From melting, drawing, heat treatment, finishing and testing .We offer nickel-based, copper-based, and iron-based alloys, including super alloy, welding materials, anti-corrosion alloy, precision alloy, FeCrAl alloy, NiCr alloy, CuNi alloy, thermocouple and etc, in the form of wire, strip, ribbon, bar, tube, plate.