Welcome to Changzhou DLX Alloy Co., Ltd.

Email:sales8@dlx-alloy.com Mobile/Whatsapp:+86 199 0611 9641

Specialized manufacturer of heaters, thermocouples and titanium,over 20 years.

Welcome to Changzhou DLX Alloy Co., Ltd.

Email:sales8@dlx-alloy.com Mobile/Whatsapp:+86 199 0611 9641

Specialized manufacturer of heaters, thermocouples and titanium,over 20 years.

Whatsapp:+86 199 0611 9641

Email:sales8@dlx-alloy.com

Add:NO.32 West Taihu Road, Xinbei District, Changzhou, Jiangsu,China

Hastelloy Alloys

Product Details

High Corrosion Resistance Hastelloy Alloy C-4 UNS N06455 Strip

Hastelloy C-4 Alloy is a nickel-chromium-molybdenum alloy known for its excellent corrosion resistance and high-temperature strength. Here are some key characteristics of Hastelloy C-4:

Composition: The alloy primarily consists of nickel (Ni), chromium (Cr), and molybdenum (Mo), with other elements like iron (Fe) and tungsten (W) in smaller amounts. It has a nominal composition of approximately 65% nickel, 16% chromium, and 16% molybdenum.

Corrosion Resistance: Hastelloy C-4 is highly resistant to a wide range of corrosive environments, including strong oxidizers, reducing acids, and chloride-induced pitting and crevice corrosion. This makes it suitable for use in chemical processing, pollution control, and waste treatment.

Thermal Stability: The alloy maintains its mechanical properties and corrosion resistance at elevated temperatures, making it suitable for applications in high-temperature environments.

Applications: Common applications of Hastelloy C-4 include components in chemical reactors, heat exchangers, piping systems, and valves. It is also used in the manufacturing of flue gas desulfurization systems, pharmaceuticals, and food processing equipment.

Fabrication and Welding: Hastelloy C-4 can be easily fabricated using conventional techniques such as welding, machining, and forming. It has good ductility and toughness, which facilitates its use in various manufacturing processes.

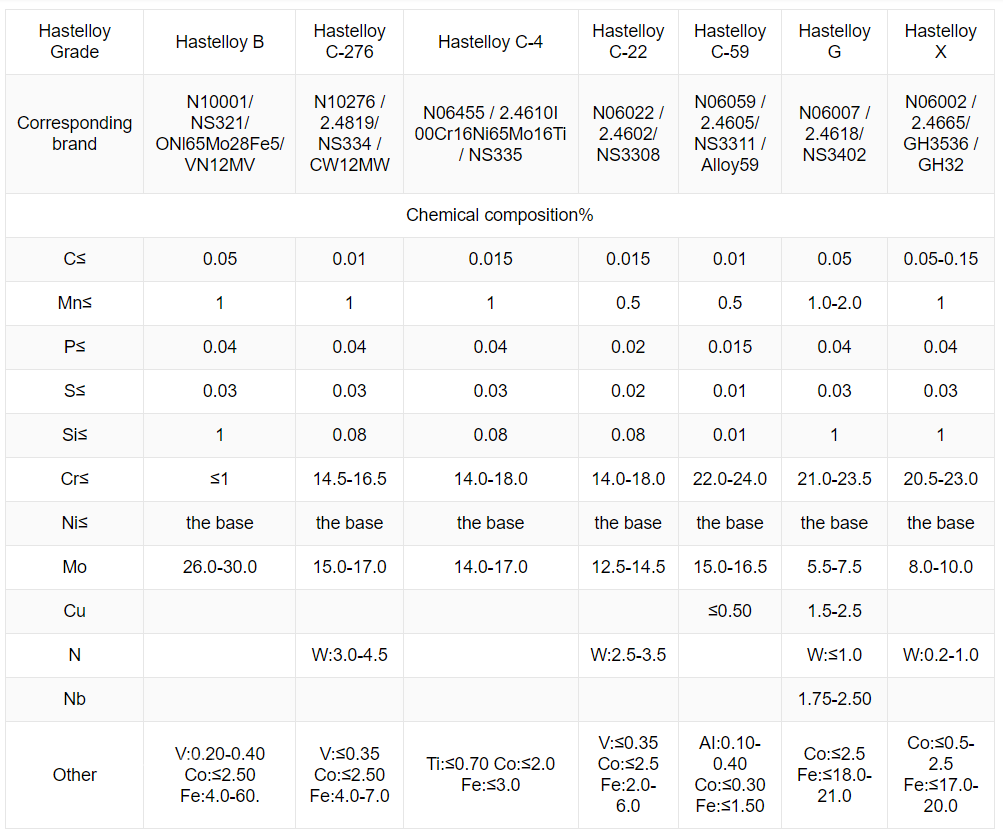

Parameter of Hastelloy Alloy Series:

| Property | Description |

|---|---|

| Chemical Composition | Nickel (65%), Chromium (16%), Molybdenum (16%), Iron (≤3%), Tungsten (≤1%), others in traces |

| Density | 8.64 g/cm³ |

| Melting Point | 1325-1370°C (2417-2498°F) |

| Corrosion Resistance | Excellent resistance to oxidizing and reducing environments, including acids and chlorides |

| Oxidation Resistance | Maintains integrity and resists scaling at high temperatures |

| Thermal Stability | Retains mechanical properties and corrosion resistance at elevated temperatures |

| Mechanical Properties | Tensile Strength: 690 MPa (100 ksi) |

| Yield Strength: 310 MPa (45 ksi) | |

| Elongation: 50% | |

| Weldability | Good, can be welded using conventional techniques |

| Fabrication | Can be easily formed, machined, and fabricated |

| Applications | Chemical processing, pollution control, flue gas desulfurization, pharmaceuticals, power generation, nuclear reactors |

| Radiation Resistance | Maintains stability under irradiation conditions |

| Oxidizing Acid Resistance | Excellent, particularly against nitric acid and mixed acid environments |

| Reducing Acid Resistance | High resistance, especially to hydrochloric acid and sulfuric acid |

| Crevice and Pitting Resistance | Strong resistance to localized corrosion in chloride-containing environments |

How Is The Hastelloy C-4 Strip Working Performance In Nuclear and Power Generation Field?

In the nuclear and power generation fields, Hastelloy C-4 strip exhibits excellent working performance due to several key properties:

High Corrosion Resistance: Hastelloy C-4 is highly resistant to a wide range of corrosive environments, including those involving strong oxidizers and reducing acids. This makes it ideal for use in nuclear reactors and other power generation systems where materials are exposed to harsh chemical environments.

High-Temperature Stability: The alloy maintains its mechanical properties and corrosion resistance at elevated temperatures, which is crucial in nuclear and power generation applications where components can be exposed to high temperatures for extended periods.

Oxidation Resistance: Hastelloy C-4 shows good resistance to oxidation, which is important in power generation systems where materials can be exposed to oxygen at high temperatures.

Radiation Resistance: The alloy's stability under irradiation conditions is a significant factor in its suitability for nuclear applications. It can withstand the effects of radiation without significant degradation of its properties.

Mechanical Strength: Hastelloy C-4 maintains its strength and structural integrity under high-temperature conditions, ensuring reliable performance in demanding applications.

Fabrication and Welding: The alloy can be readily fabricated and welded, which is important for manufacturing complex components used in nuclear reactors and power generation systems.

Nuclear Reactors: Hastelloy C-4 strips are used in various components of nuclear reactors, including heat exchangers, pressure vessels, and piping systems. The alloy's ability to resist corrosion and maintain strength at high temperatures ensures the safety and efficiency of the reactor.

Heat Exchangers: In both nuclear and conventional power plants, heat exchangers are critical components. Hastelloy C-4's excellent thermal stability and corrosion resistance make it ideal for heat exchanger tubes and plates.

Steam Generators: In nuclear power plants, steam generators convert water into steam using the heat produced by nuclear fission. Hastelloy C-4 strips are used in the construction of steam generator components due to their ability to withstand high temperatures and corrosive environments.

Turbine Blades and Components: In power generation, turbine blades and other components are exposed to high temperatures and corrosive gases. Hastelloy C-4 strips can be used in the manufacturing of these components, ensuring durability and efficiency.

Overall, Hastelloy C-4 strips provide reliable performance in nuclear and power generation applications, contributing to the safety, efficiency, and longevity of critical systems.

FAQ:

What is your working time?

Monday-Saturday : 7:30AM-17:00PM (Beijing time, GMT+08.00)

We have public holiday during May.1-3, Oct.1-7 and Chinese New Year holiday . Pls email us during our holiday if u have any question.

Do you provide free samples?

Yes, we can provide a free sample for testing,buyer should bear all the shipping costs.

What is your payment terms?

T/T,L/C,D/A,D/P,Western Union,MoneyGram,Paypal

What is the lead time of sample order?

Usually sample lead time is 7-15 days after payment has been confirmed.