Welcome to Changzhou DLX Alloy Co., Ltd.

Email:sales8@dlx-alloy.com Mobile/Whatsapp:+86 199 0611 9641

Specialized manufacturer of heaters, thermocouples and titanium,over 20 years.

Welcome to Changzhou DLX Alloy Co., Ltd.

Email:sales8@dlx-alloy.com Mobile/Whatsapp:+86 199 0611 9641

Specialized manufacturer of heaters, thermocouples and titanium,over 20 years.

Whatsapp:+86 199 0611 9641

Email:sales8@dlx-alloy.com

Add:NO.32 West Taihu Road, Xinbei District, Changzhou, Jiangsu,China

Hastelloy Alloys

Product Details

UNS N06022 Nicke Alloy Coil Hastelloy C22 Strips

Hastelloy C-22 is renowned for its exceptional corrosion resistance, particularly in environments with strong acids and chlorides, making it ideal for highly corrosive applications. This alloy also boasts impressive high-temperature strength, ensuring reliable performance in elevated temperature settings. The strip form of Hastelloy C-22 offers excellent plasticity and processability, allowing for customization to meet specific customer requirements.

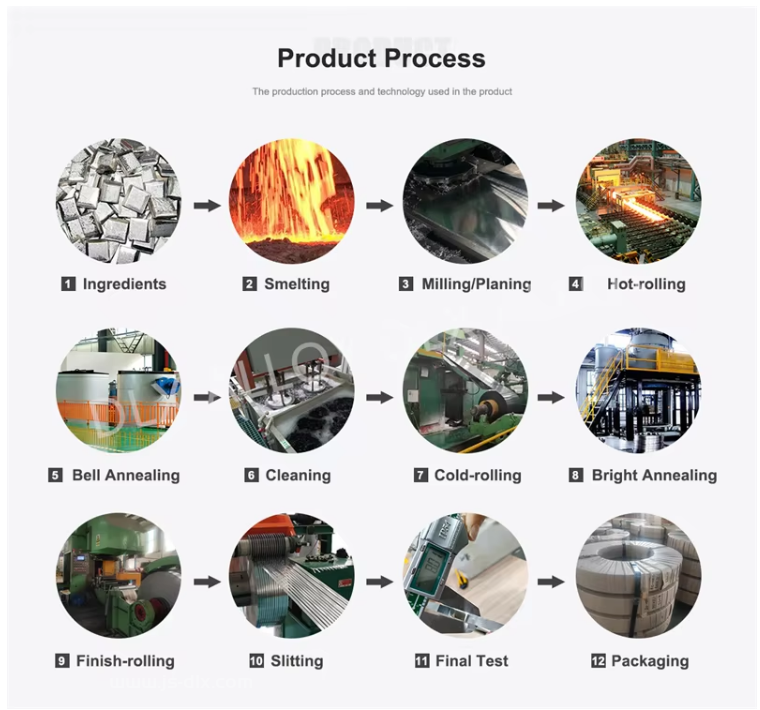

As a high-performance alloy, Hastelloy C-22 is extensively utilized across various industries, including petrochemical, chemical processing, aerospace, and marine engineering. Our Hastelloy C-22 strips adhere to ASTM B575 standards and are produced using advanced manufacturing techniques and top-quality raw materials. Each strip undergoes precision processing and rigorous testing to ensure superior surface quality, accuracy, and durability.

1. Excellent Corrosion Resistance:

Highly resistant to pitting, crevice corrosion, and stress corrosion cracking, especially in environments with strong acids and chlorides.

2. High-Temperature Strength:

Maintains mechanical strength and stability in elevated temperature applications.

3. Good Plasticity and Processability:

Easily fabricated and formed into various shapes, allowing for customization based on specific requirements.

4. Versatility:

Suitable for a wide range of applications across industries such as petrochemical, chemical processing, aerospace, and marine engineering.

5. Compliance with Standards:

Manufactured in accordance with ASTM B575 standards, ensuring quality and consistency.

6. Precision Processing:

Undergoes rigorous testing and precision processing to guarantee excellent surface quality and performance.

7. Durability:

Long-lasting performance in highly corrosive environments, reducing the need for frequent replacements.

These features make Hastelloy C-22 strip a preferred choice for demanding applications where reliability and performance are critical.

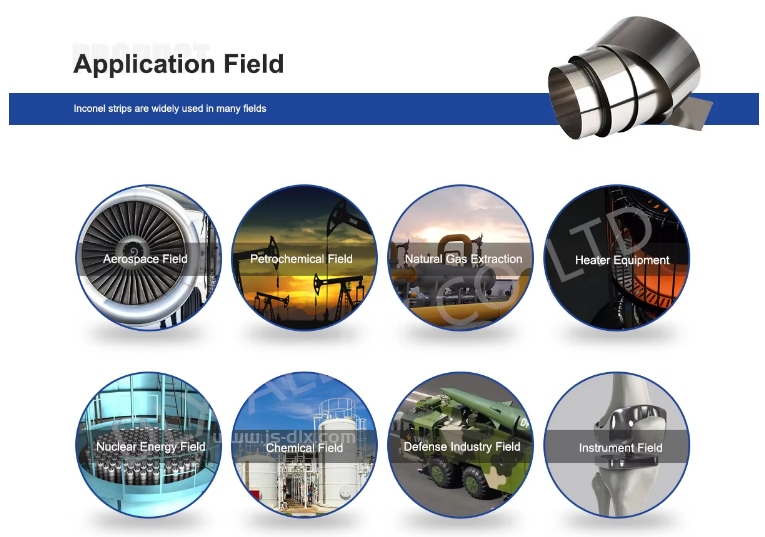

The Main Applications Of Hastelloy C22 Strips:

1. Petrochemical Industry: Used in the production of chemicals and refining processes due to its resistance to corrosive environments.

2. Chemical Processing: Ideal for equipment and components exposed to aggressive chemicals, including reactors, heat exchangers, and piping systems.

3. Aerospace: Utilized in components that require high strength and corrosion resistance at elevated temperatures.

4. Marine Engineering: Employed in seawater applications, including shipbuilding and offshore platforms, due to its excellent resistance to chloride-induced corrosion.

5. Pharmaceuticals: Used in manufacturing equipment that must withstand corrosive substances while maintaining high purity standards.

6. Nuclear Industry: Suitable for use in components that require high corrosion resistance and stability under extreme conditions.

7. Environmental Technology: Applied in waste treatment and pollution control systems, where resistance to aggressive chemicals is crucial.

These applications highlight the versatility and reliability of Hastelloy C-22 strip in demanding environments.

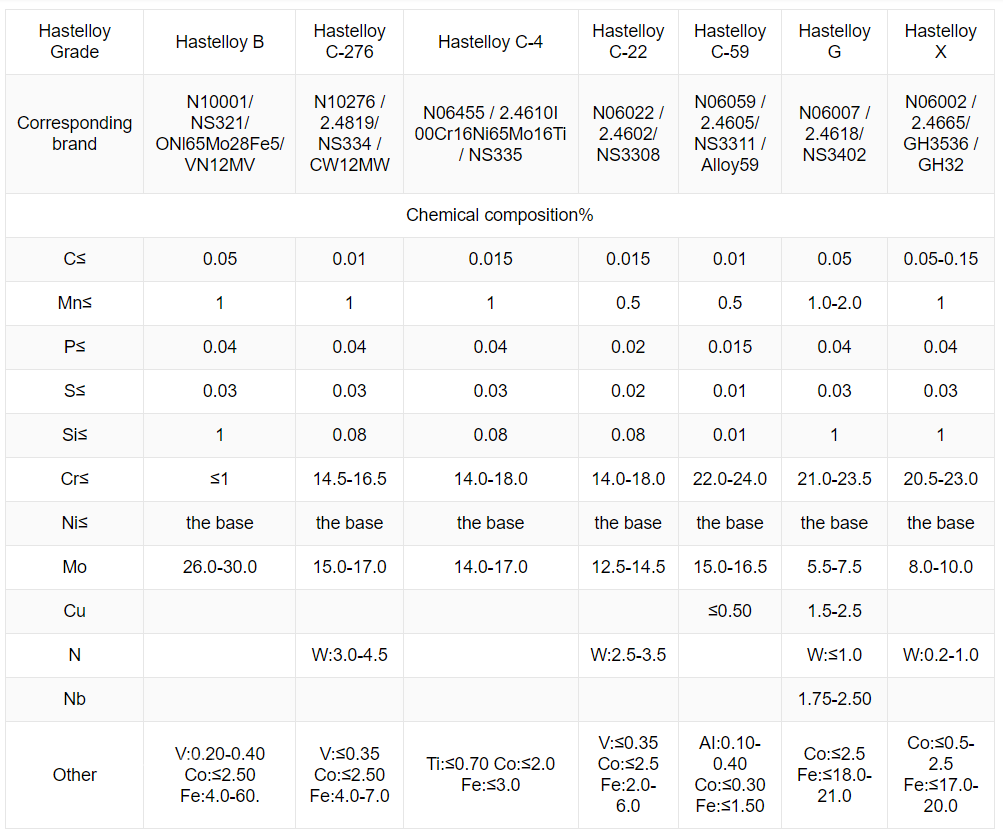

Parameter of Hastelloy Alloy Series:

What Are The Main Applications Of Hastelloy C-276 Strip?

1. Pipelines and Vessels: Used in the construction of pipelines, reactors, and storage vessels that handle corrosive chemicals, including acids and chlorides.

Heat Exchangers: Employed in heat exchangers where resistance to corrosion and high temperatures is critical.

2. Oil and Gas Industry

Downhole Equipment: Utilized in downhole tools and components that operate in harsh environments, including high temperatures and corrosive fluids.

Refinery Applications: Used in various processes within refineries, such as in distillation columns and reactors.

3. Marine Applications

Seawater Systems: Suitable for components exposed to seawater and marine environments, providing resistance to pitting and crevice corrosion.

4. Pharmaceuticals

Manufacturing Equipment: Employed in equipment used in the production of pharmaceuticals, where high purity and corrosion resistance are essential.

5. Aerospace

Engine Components: Used in aerospace applications, particularly in components that require high strength and resistance to oxidation at elevated temperatures.

6. Nuclear Industry

Nuclear Reactors: Used in components that require resistance to radiation and high temperatures, ensuring reliability and performance.

7. Environmental Applications

Scrubbers: Utilized in flue gas desulfurization systems and other pollution control equipment where corrosive gases are present.

FAQ:

What is your working time?

Monday-Saturday : 7:30AM-17:00PM (Beijing time, GMT+08.00)

We have public holiday during May.1-3, Oct.1-7 and Chinese New Year holiday . Pls email us during our holiday if u have any question.

Do you provide free samples?

Yes, we can provide a free sample for testing,buyer should bear all the shipping costs.

What is your payment terms?

T/T,L/C,D/A,D/P,Western Union,MoneyGram,Paypal

What is the lead time of sample order?

Usually sample lead time is 7-15 days after payment has been confirmed.