Welcome to Changzhou DLX Alloy Co., Ltd.

Email:sales8@dlx-alloy.com Mobile/Whatsapp:+86 199 0611 9641

Specialized manufacturer of heaters, thermocouples and titanium,over 20 years.

Welcome to Changzhou DLX Alloy Co., Ltd.

Email:sales8@dlx-alloy.com Mobile/Whatsapp:+86 199 0611 9641

Specialized manufacturer of heaters, thermocouples and titanium,over 20 years.

Whatsapp:+86 199 0611 9641

Email:sales8@dlx-alloy.com

Add:NO.32 West Taihu Road, Xinbei District, Changzhou, Jiangsu,China

Hastelloy Alloys

Product Details

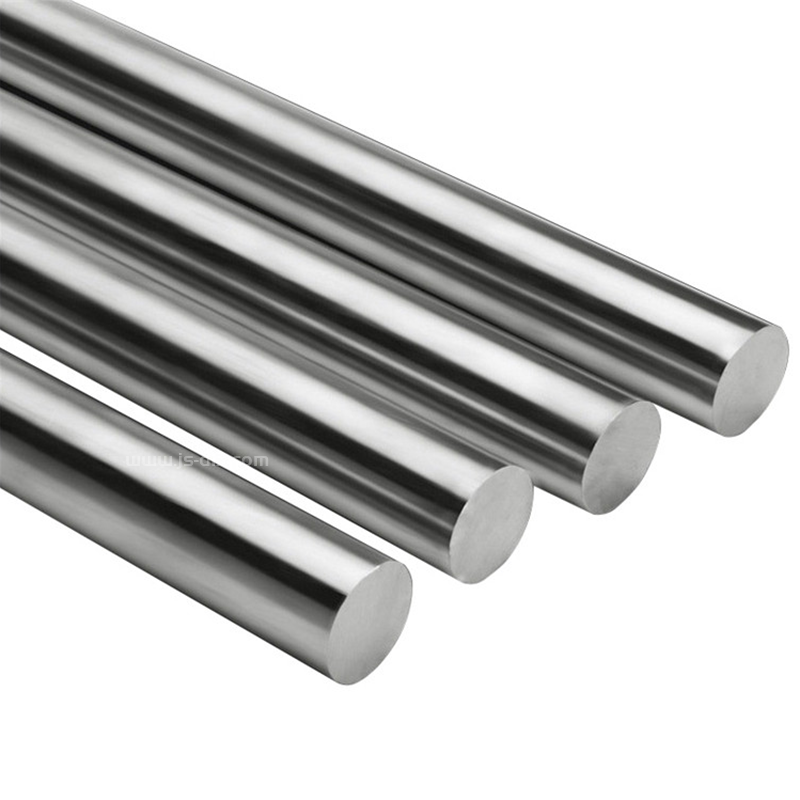

UNS N10276 Nickel Alloy C276 Hastelloy C-276 Round Bars for Extreme Corrosion Resistance

Hastelloy C276 Bar is a high-performance alloy known for its exceptional resistance to a wide range of corrosive environments. This alloy is a nickel-molybdenum-chromium superalloy with the addition of tungsten, designed to withstand some of the harshest conditions, including strong oxidizing and reducing acids, pitting, crevice corrosion, and stress corrosion cracking. The unique combination of elements in Hastelloy C276 makes it one of the most versatile corrosion-resistant materials available, widely used in chemical processing, pollution control, oil and gas, marine, and other industries where high corrosion resistance is paramount.

Why Hastelloy C276 Have High Resistant To Various Forms Of Corrosion?

Hastelloy C276 exhibits high resistance to various forms of corrosion due to its unique chemical composition and microstructure, which provide a synergistic effect against a wide range of corrosive environments. Here’s why Hastelloy C276 is so effective at resisting corrosion:

Role: Nickel forms the base of Hastelloy C276 and constitutes about 57% of the alloy.

Effect: High nickel content contributes significantly to the alloy’s overall corrosion resistance, particularly in reducing environments. It provides excellent resistance to a wide variety of acids, including hydrochloric acid and sulfuric acid, and also prevents stress corrosion cracking.

Role: Molybdenum is present in the alloy at 15-17%.

Effect: Molybdenum enhances the resistance to pitting and crevice corrosion, which are localized forms of attack common in chloride-containing environments. It also improves the alloy’s performance in reducing environments, such as those found in chemical processing plants.

Role: Chromium is another key component, present at 14.5-16.5%.

Effect: Chromium imparts resistance to oxidizing environments by forming a stable, passive oxide film on the surface of the alloy. This film acts as a barrier that protects the underlying metal from further corrosion, making Hastelloy C276 effective against strong oxidizers like ferric and cupric chlorides, chlorine, and nitric acid.

Role: Tungsten is included at 3-4.5%.

Effect: Tungsten further enhances pitting resistance, particularly in environments with aggressive chlorides. Its presence complements the effects of molybdenum, providing a robust defense against localized attack.

Role: Carbon is kept at very low levels (0.01% max).

Effect: Low carbon content minimizes the risk of carbide precipitation during welding, which could otherwise lead to intergranular corrosion. This makes the alloy easier to weld without compromising its corrosion resistance.

Effect: Hastelloy C276’s balanced composition enables it to resist both acidic and alkaline environments. This versatility is crucial in applications where the pH may vary or where multiple corrosive agents are present.

Role: The combination of nickel, chromium, and molybdenum facilitates the formation of a stable passive film on the alloy’s surface.

Effect: This film is self-repairing if damaged, which enhances the alloy’s durability and longevity in corrosive environments, as it continually protects against further attack.

Role: The alloy’s composition, particularly the high nickel and chromium content, helps prevent stress corrosion cracking, a form of corrosion that occurs under tensile stress in the presence of specific ions like chlorides.

Effect: This makes Hastelloy C276 suitable for high-stress applications where conventional materials might fail.

Effect: Hastelloy C276 maintains a stable microstructure even at high temperatures, which helps prevent phase separation and other changes that could reduce corrosion resistance.

These combined factors make Hastelloy C276 one of the most corrosion-resistant alloys available, capable of withstanding harsh and varied environments where other materials would degrade quickly. Its broad-spectrum resistance to corrosion ensures that it remains a top choice for critical applications in industries like chemical processing, oil and gas, and pollution control.

| Element | Composition (Weight %) | Remarks |

|---|---|---|

| Nickel (Ni) | 57.0 min | Base metal, primary element providing corrosion resistance. |

| Chromium (Cr) | 14.5 - 16.5 | Enhances oxidation and corrosion resistance. |

| Molybdenum (Mo) | 15.0 - 17.0 | Increases strength, hardness, and resistance to pitting. |

| Iron (Fe) | 4.0 - 7.0 | Minor element, balances alloy and improves workability. |

| Tungsten (W) | 3.0 - 4.5 | Adds to corrosion resistance and enhances the alloy's high-temperature strength. |

| Cobalt (Co) | 2.5 max | Present as a minor impurity, not intentionally added. |

| Manganese (Mn) | 1.0 max | Minor element, can impact the alloy's hardness and strength. |

| Vanadium (V) | 0.35 max | Improves strength, though present in small quantities. |

| Silicon (Si) | 0.08 max | Minor element, should be kept low to maintain weldability. |

| Carbon (C) | 0.01 max | Low carbon content to prevent carbide precipitation and enhance weldability. |

| Phosphorus (P) | 0.04 max | Trace element, should be minimized as it can affect mechanical properties. |

| Sulfur (S) | 0.03 max | Impurity that should be minimized to avoid compromising corrosion resistance. |

| Parameter | Value | Remarks |

|---|---|---|

| Density | 8.89 g/cm³ | High density due to the heavy alloying elements. |

| Melting Point | 1325-1370°C | High melting point for high-temperature applications. |

| Tensile Strength | 690 MPa (min) | Indicates the maximum stress the material can withstand while being stretched or pulled. |

| Yield Strength | 283 MPa (min) | Stress at which the material begins to deform plastically. |

| Elongation | 40% | Measures ductility; higher values indicate better ductility. |

| Hardness (Rockwell B) | 85 (max) | Moderate hardness, suitable for various industrial applications. |

| Modulus of Elasticity | 205 GPa | Measures stiffness; a high modulus indicates a rigid material. |

| Thermal Conductivity | 10.2 W/m·K | Lower thermal conductivity typical of high-performance alloys. |

| Electrical Resistivity | 1.28 µΩ·m | High resistivity, typical of alloys with nickel and chromium. |

What is your working time?

Monday-Saturday : 7:30AM-17:00PM (Beijing time, GMT+08.00)

We have public holiday during May.1-3, Oct.1-7 and Chinese New Year holiday . Pls email us during our holiday if u have any question.

What is your payment terms?

T/T,L/C,D/A,D/P,Western Union,MoneyGram,Paypal

What is the lead time of sample order?

Usually sample lead time is 7-15 days after payment has been confirmed.