Welcome to Changzhou DLX Alloy Co., Ltd.

Email:sales8@dlx-alloy.com Mobile/Whatsapp:+86 199 0611 9641

Specialized manufacturer of heaters, thermocouples and titanium,over 20 years.

Welcome to Changzhou DLX Alloy Co., Ltd.

Email:sales8@dlx-alloy.com Mobile/Whatsapp:+86 199 0611 9641

Specialized manufacturer of heaters, thermocouples and titanium,over 20 years.

Whatsapp:+86 199 0611 9641

Email:sales8@dlx-alloy.com

Add:NO.32 West Taihu Road, Xinbei District, Changzhou, Jiangsu,China

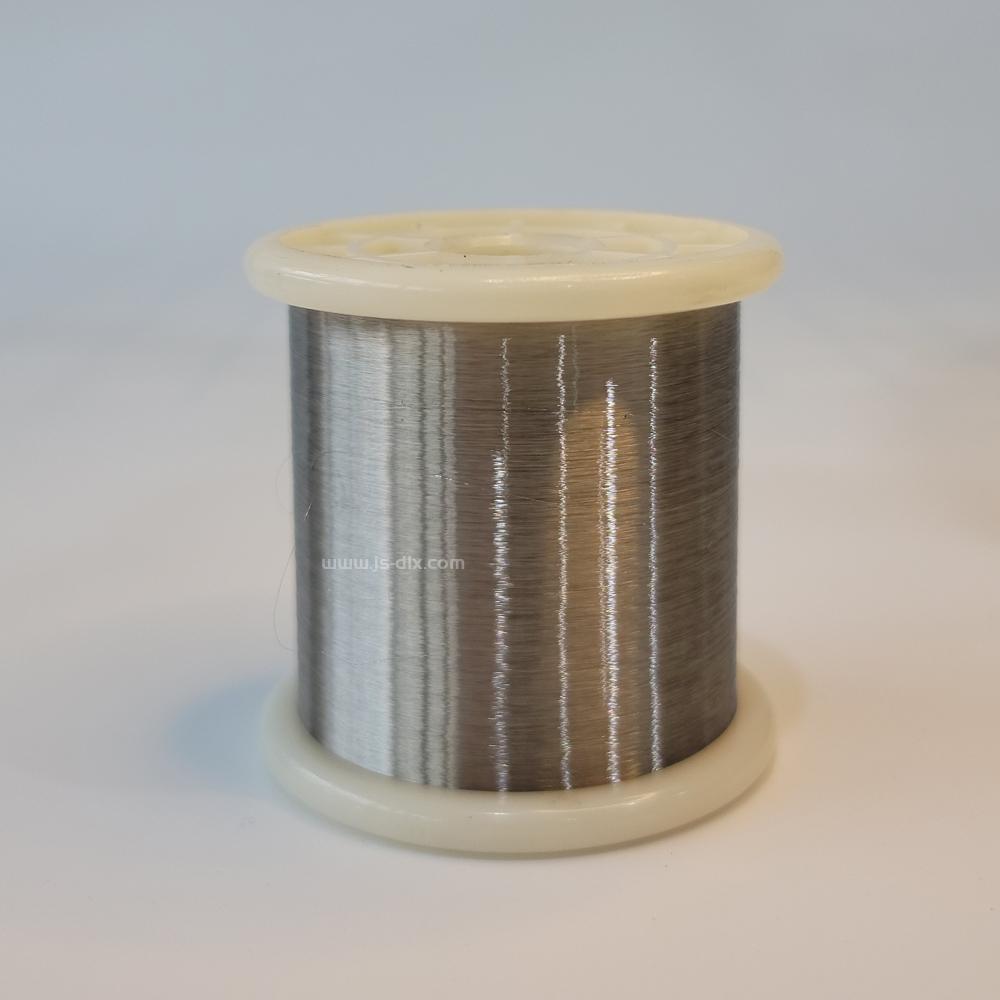

Hastelloy Alloys

Product Details

Our Hastelloy Alloy is a special type of alloy that is designed to withstand high temperatures and pressure. It is made from a combination of nickel, molybdenum, and chromium, which gives it excellent resistance to corrosion and oxidation. This makes it ideal for use in a variety of applications, including heat exchangers, chemical processing, and more.

Our Hastelloy Alloy is available in a variety of grades and models, including the N06985 model. This model has a tensile strength of 690 MPa, making it incredibly strong and durable. It is also designed to resist corrosion, making it ideal for use in harsh environments.

One of our most popular grades of Hastelloy Alloy is the Hastelloy C-276/N10276/2.4819. This grade is known for its excellent corrosion resistance and is often used in chemical processing and other applications where corrosion is a concern. It is also highly resistant to pitting and crevice corrosion, making it ideal for use in harsh environments.

Our Hastelloy Alloy is available in a variety of forms, including Hastelloy B2, Hastelloy Material, and Hastelloy C276 Plate. Each of these forms has its own unique properties and benefits, making it easy to find the perfect solution for your specific needs.

When you order our Hastelloy Alloy, you can rest assured that you are getting the highest quality product on the market. We use only the best materials and manufacturing processes to ensure that our products meet the highest standards of quality and durability.

All of our Hastelloy Alloy products come with standard export packing, making it easy to transport and store your product. Whether you need a small quantity or a large order, we can accommodate your needs and provide you with the best possible service.

So if you're looking for a high-quality alloy that can withstand high temperatures and pressure, look no further than Hastelloy Alloy. With its excellent corrosion resistance, strength, and durability, it is the perfect solution for your heat exchanger needs.

Product Name: Hastelloy Alloy

Technique: Cold-Drawn Hot Rolled

Grade: Hastelloy C-276 / N10276 / 2.4819

Special Use: Heat Exchanger

Tensile Strength: 690 MPa

Powder Or Not: Not Powder

This Hastelloy Alloy product is made of Hastelloy C-276 / N10276 / 2.4819 grade material and has a tensile strength of 690 MPa. Its technique is cold-drawn hot rolled and it is specially used for heat exchanger applications. This product is not in powder form and is ideal for various industrial uses.

| Powder Or Not | Not Powder |

| Tensile Strength | 690 MPa |

| Type Of Tube | Straight Tube, U Bend Tube, Coil Tube |

| Grade | Hastelloy C-276 / N10276 / 2.4819 |

| Tensile Strength Rm | 690 N/mm² |

| Keyword | Hasteloy Alloy B-4 Sheet |

| Yield Strength | 310 MPa |

| Features | Corrosion Resistance |

| Technique | Cold-Drawn Hot Rolled |

| Packing | Standard Export Packing |

Related keywords: Hastelloy C22, Hastelloy C 276, Hastelloy Material

One of the primary applications of the Hastelloy Alloy is in the manufacturing of heat exchangers. It is perfect for use in heat exchanger applications because of its resistance to corrosion, even in highly corrosive environments. The Hastelloy Alloy is often used in industries such as chemical processing, oil and gas, and pharmaceuticals because it can withstand high temperatures and pressures.

The DLX Hastelloy Alloy is also suitable for use in the manufacturing of pumps, valves, and pipes. It is highly resistant to pitting and crevice corrosion, making it ideal for use in harsh environments, such as offshore oil rigs.

DLX Hastelloy Alloy is available in different models, including Hastelloy C22 and Hastelloy B2. Hastelloy C22 is a versatile alloy that can resist corrosion in both oxidizing and reducing environments. It is perfect for use in chemical processing industries that use different acids, such as sulfuric acid, hydrochloric acid, and nitric acid. On the other hand, Hastelloy B2 is ideal for use in reducing environments with sulfuric acid concentrations of up to 80%.

To sum it up, the DLX Hastelloy Alloy is a high-performance alloy steel material that is suitable for use in various industrial applications. Its superior properties, which include resistance to corrosion, high tensile strength, and high temperature and pressure resistance, make it perfect for use in different industries, including chemical processing, oil and gas, pharmaceuticals, and offshore oil rigs.

Looking for product customization services for your Hastelloy Alloy needs? Look no further than DLX! Our Hastelloy Alloy, model number Hastelloy C-276 / N10276 / 2.4819, is made in China and boasts a tensile strength Rm of 690 N/mm². This material is perfect for heat exchanger applications and comes with standard export packing.

With our customization services, we can also provide you with Hastelloy C22 and other Hastelloy materials, as well as alloy steel materials to meet your specific needs. Contact us today to learn more!

Keywords: Hastelloy Alloy B-4 Sheet, Hastelloy C22, Hastelloy Material, Alloy Steel Material

Hastelloy Alloy is a high-performance material that exhibits excellent resistance to corrosion, oxidation, and other forms of degradation. To ensure the continued reliability and performance of your Hastelloy Alloy product, we offer a range of technical support and services.

Our team of experts is available to provide assistance with product selection, material testing, and design optimization. We can also offer guidance on installation, maintenance, and repair, as well as troubleshooting and problem-solving support.

In addition, we offer a range of value-added services, including custom fabrication, machining, and finishing. Our state-of-the-art facilities and experienced technicians enable us to provide high-quality solutions tailored to your specific needs.

Whether you are looking for technical support, consultation, or value-added services, our team is committed to providing you with the expertise and resources you need to get the most out of your Hastelloy Alloy product.

Product Packaging:

The Hastelloy Alloy products will be packaged securely in durable plastic bags.

The bags will be placed in sturdy cardboard boxes with adequate cushioning to prevent damage during transit.

The boxes will be labeled with the product name, size, and quantity.

Shipping:

We offer worldwide shipping via air or sea.

Shipping costs will be calculated based on the destination and weight of the package.

We will provide a tracking number once the package has been shipped.

Please note that the customer is responsible for any customs fees or taxes that may apply in their country.

Q: What is DLX Hastelloy Alloy?

A: DLX Hastelloy Alloy is a high-performance alloy made in China that is widely used in various industrial applications due to its excellent corrosion resistance and strength.

Q: What are the main features of DLX Hastelloy Alloy?

A: DLX Hastelloy Alloy is known for its exceptional resistance to corrosion, both in acidic and alkaline environments. It also has high strength and can withstand high temperatures.

Q: What are the common applications of DLX Hastelloy Alloy?

A: DLX Hastelloy Alloy is often used in chemical processing, aerospace, marine engineering, and oil and gas industries due to its resistance to corrosion and high temperatures.

Q: How is DLX Hastelloy Alloy made?

A: DLX Hastelloy Alloy is made using a combination of nickel, chromium, and molybdenum, along with other trace elements. The alloy is produced using a specialized melting process to ensure consistency and quality.

Q: What are the advantages of using DLX Hastelloy Alloy?

A: The advantages of using DLX Hastelloy Alloy include its exceptional resistance to corrosion, high strength, and ability to withstand high temperatures. It also has a long lifespan and requires minimal maintenance, making it a cost-effective choice for industrial applications.