Welcome to Changzhou DLX Alloy Co., Ltd.

Email:sales8@dlx-alloy.com Mobile/Whatsapp:+86 199 0611 9641

Specialized manufacturer of heaters, thermocouples and titanium,over 20 years.

Welcome to Changzhou DLX Alloy Co., Ltd.

Email:sales8@dlx-alloy.com Mobile/Whatsapp:+86 199 0611 9641

Specialized manufacturer of heaters, thermocouples and titanium,over 20 years.

Whatsapp:+86 199 0611 9641

Email:sales8@dlx-alloy.com

Add:NO.32 West Taihu Road, Xinbei District, Changzhou, Jiangsu,China

Hastelloy Alloys

Product Details

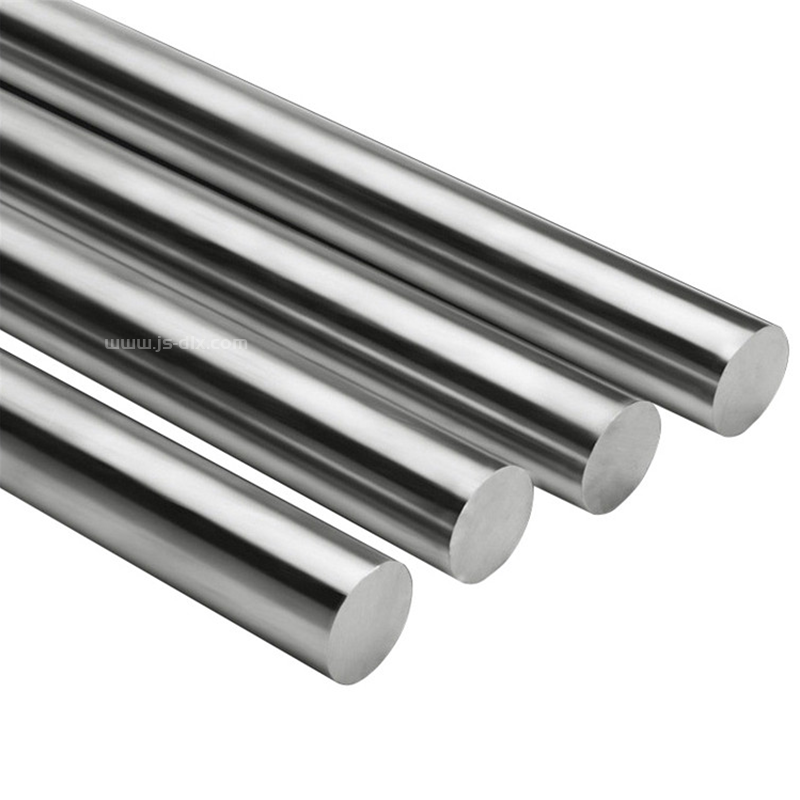

ASTM B574 Nickel Alloy Hastelloy C22 Bar: High Corrosion Resistance & Excellent Durability

Hastelloy C22 bars are renowned for their exceptional resistance to corrosion and high-temperature environments, making them a crucial material in industries that require superior performance under harsh conditions. Developed as part of the nickel-chromium-molybdenum alloy family, Hastelloy C22 offers a unique blend of properties that makes it an ideal choice for a wide range of applications, including chemical processing, petrochemical, pharmaceuticals, and pollution control.

Hastelloy C22 is primarily composed of nickel (approximately 56%), chromium (20-22%), and molybdenum (12.5-14.5%), with the addition of tungsten, iron, and small amounts of other elements. This specific composition enhances its resistance to various types of corrosion, including:

Pitting and Crevice Corrosion: Its high molybdenum content provides excellent resistance to localized attacks, such as pitting and crevice corrosion, which are common in chloride-rich environments.

Oxidizing and Reducing Environments: The balanced mixture of chromium, molybdenum, and tungsten enables Hastelloy C22 to resist both oxidizing and reducing acids, such as sulfuric, hydrochloric, and nitric acids.

Stress Corrosion Cracking: The nickel content imparts resistance to stress corrosion cracking, which is critical in environments where temperature and stress factors can degrade other materials.

Hastelloy C22 bars are not just resistant to corrosion but also maintain excellent mechanical properties across a wide temperature range. Key mechanical properties include:

High Yield Strength: The bars have a high yield strength, which provides stability and resistance to deformation under load.

Excellent Ductility and Toughness: Hastelloy C22 retains its toughness even at cryogenic temperatures, allowing it to withstand impact and stress without fracturing.

Thermal Stability: It exhibits outstanding performance in both high and low temperatures, making it suitable for a variety of thermal applications.

Hastelloy C22 bars are produced in accordance with stringent international standards to ensure quality and consistency. Common standards include:

ASTM B574: This specification covers nickel-molybdenum-chromium-tungsten alloy bars used in various applications.

ASME SB574: The ASME standard is aligned with ASTM, ensuring the material’s suitability for pressure-containing parts.

ISO 6208: This international standard further ensures the bar's suitability for global industrial applications, offering confidence in its performance.

One of the standout features of Hastelloy C22 is its excellent weldability. It can be welded using conventional methods, including gas tungsten arc welding (GTAW), gas metal arc welding (GMAW), and shielded metal arc welding (SMAW). This allows for the creation of complex components without compromising the integrity of the material. The alloy also shows good formability and machinability, making it adaptable for various industrial processes.

Hastelloy C22 bars are employed across a range of industries due to their robustness and adaptability:

Chemical Processing: The alloy is used in reactors, heat exchangers, and piping systems that handle highly corrosive chemicals.

Pharmaceuticals: It is utilized in equipment where cleanliness and resistance to aggressive cleaning agents are paramount.

Oil and Gas: Hastelloy C22’s durability under extreme conditions makes it ideal for equipment exposed to sour gas environments.

Pollution Control: The bars are used in systems for flue gas desulfurization and other processes that involve aggressive gases and liquids.

Compared to other corrosion-resistant alloys, Hastelloy C22 offers superior versatility and reliability. Its ability to withstand a wide range of corrosive environments, combined with its mechanical strength, makes it a preferred choice over stainless steels and other nickel alloys in demanding applications.

Hastelloy C22 bars represent a pinnacle of material engineering, offering a combination of excellent corrosion resistance, high mechanical strength, and adaptability across numerous industries. Whether dealing with highly acidic, oxidizing, or reducing environments, Hastelloy C22 provides a robust solution that ensures long-term performance and reliability. As industries continue to demand materials that can endure more aggressive conditions, Hastelloy C22 stands out as a versatile and essential alloy.

Composition of various Hastelloy Alloys:

| Alloy | Nickel (Ni) | Chromium (Cr) | Molybdenum (Mo) | Iron (Fe) | Tungsten (W) | Cobalt (Co) | Manganese (Mn) | Carbon (C) | Silicon (Si) | Other Elements |

|---|---|---|---|---|---|---|---|---|---|---|

| Hastelloy C22 | 56 | 20-22 | 12.5-14.5 | 2-6 | 2.5-3.5 | 2.5 max | 0.5 max | 0.015 max | 0.08 max | Cu: 0.5 max, P: 0.02 max |

| Hastelloy C276 | 57 | 14.5-16.5 | 15-17 | 4-7 | 3-4.5 | 2.5 max | 1 max | 0.01 max | 0.08 max | Cu: 0.5 max, P: 0.02 max |

| Hastelloy B2 | Balance | 1 max | 26-30 | 1-2 | - | 1 max | 1 max | 0.01 max | 0.08 max | - |

| Hastelloy X | 47 | 20.5-23 | 8-10 | 17-20 | 0.2-1 max | 0.5-2.5 | 1 max | 0.15 max | 0.5 max | Al: 0.2 max, Ti: 0.6 max |

Physical properties of various Hastelloy alloys:

| Alloy | Density (g/cm³) | Melting Range (°C) | Thermal Conductivity (W/m·K) | Specific Heat Capacity (J/kg·K) | Electrical Resistivity (µΩ·cm) | Modulus of Elasticity (GPa) | Poisson’s Ratio |

|---|---|---|---|---|---|---|---|

| Hastelloy C22 | 8.69 | 1325-1370 | 11.7 | 450 | 1.05 | 210 | 0.31 |

| Hastelloy C276 | 8.89 | 1325-1370 | 12.0 | 450 | 1.07 | 210 | 0.31 |

| Hastelloy B2 | 9.24 | 1330-1380 | 11.5 | 430 | 1.02 | 205 | 0.31 |

| Hastelloy X | 8.22 | 1260-1355 | 12.5 | 460 | 1.08 | 200 | 0.33 |

What is your working time?

Monday-Saturday : 7:30AM-17:00PM (Beijing time, GMT+08.00)

We have public holiday during May.1-3, Oct.1-7 and Chinese New Year holiday . Pls email us during our holiday if u have any question.

What is your payment terms?

T/T,L/C,D/A,D/P,Western Union,MoneyGram,Paypal

What is the lead time of sample order?

Usually sample lead time is 7-15 days after payment has been confirmed.